500MPa-grade hot-rolled coiled reinforced bar and production method thereof

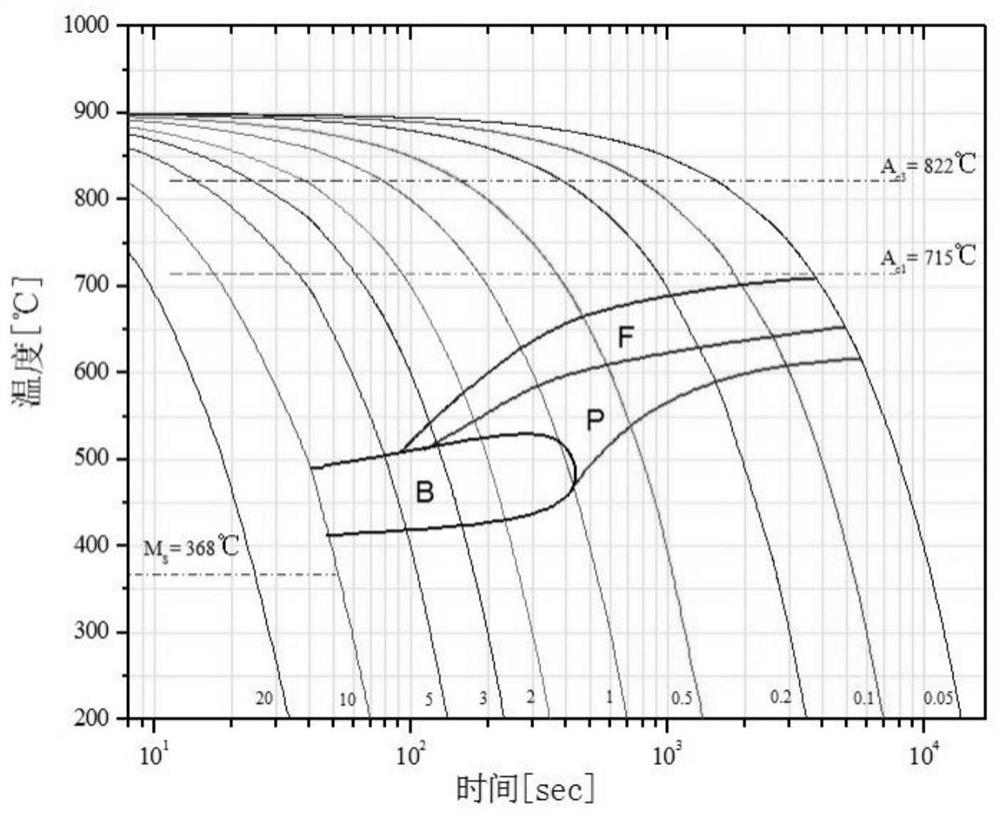

A production method and coiling technology, which are applied in 500MPa hot-rolled coiling and its production field, can solve the problems of unfavorable heating temperature for solid solution of niobium element, insufficient production power, and only high strength of steel bars, etc., so as to facilitate on-site operation and The effects of forward production, reduction of bainite nucleation and growth, and improvement of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention are described in detail below, which, as a part of the description, illustrate the principle of the present invention through examples, and other aspects, features and advantages of the present invention will become clear through the detailed description.

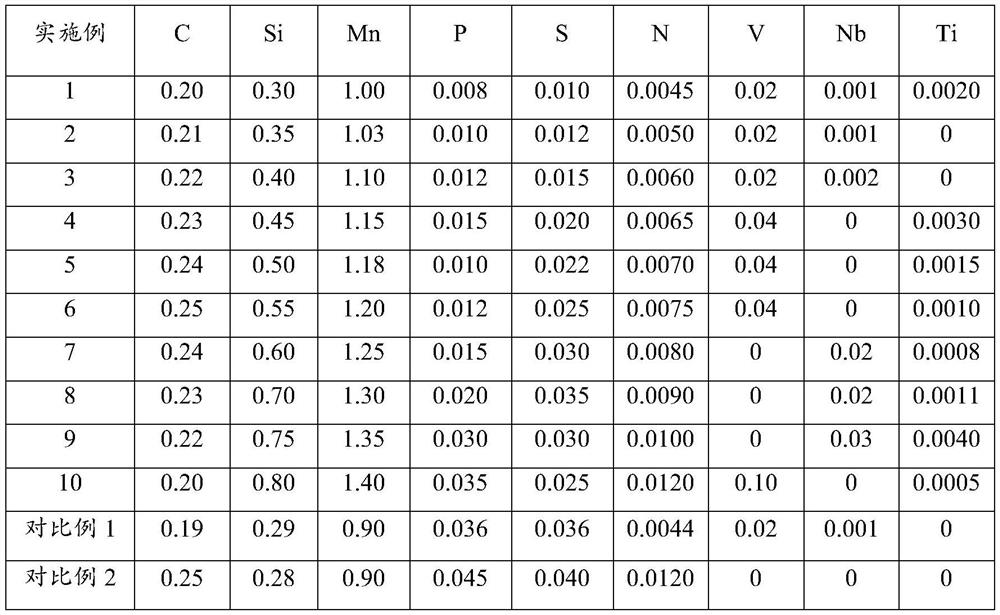

[0044] Table 1 is the value of the chemical composition of each embodiment of the present invention and comparative examples;

[0045] Table 2 is each embodiment of the present invention and comparative example smelting process technological parameter;

[0046] Table 3 is each embodiment of the present invention and comparative example rolling process technological parameter;

[0047] Table 4 is the experimental results of various embodiments of the present invention and comparative examples.

[0048] Each embodiment of the present invention is produced according to the following steps:

[0049] (1) Hot metal pretreatment, the P and S contents of the hot metal from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com