A suction-combined electrochemical micro-additive preparation method and device thereof

An electrochemical and combined technology, applied in the field of additive manufacturing, can solve the problems of poor shape of finished products, difficult control of meniscus size, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

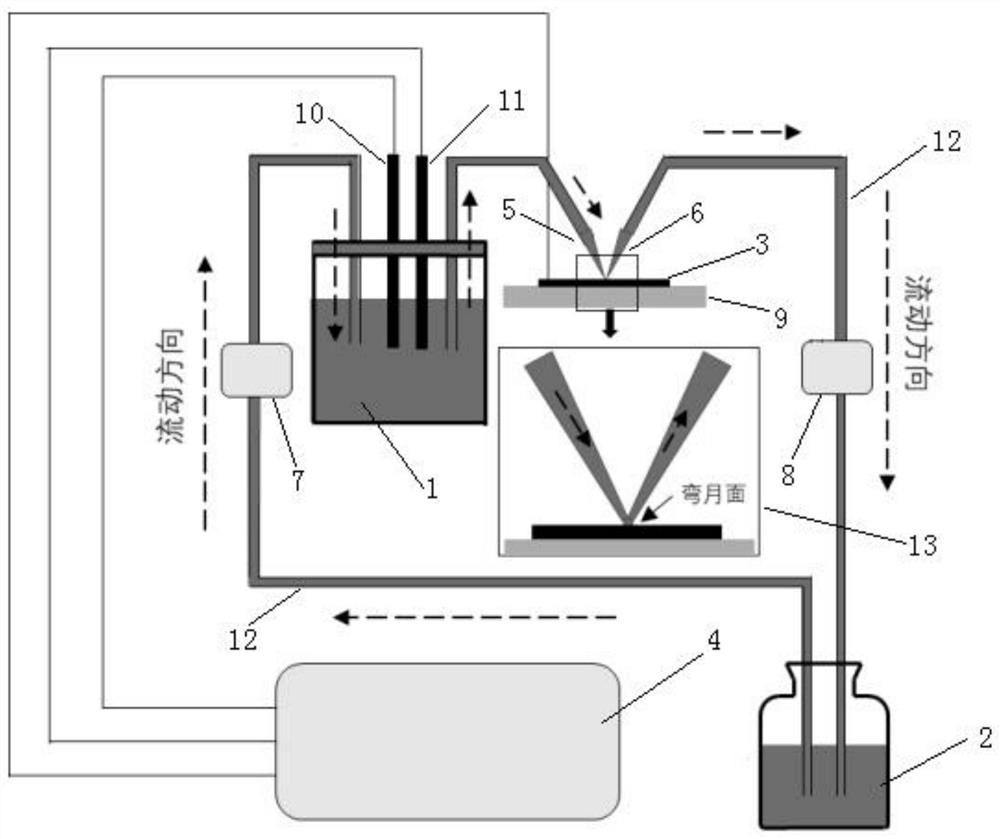

[0039] Example 1 A suction-combined electrochemical micro-additive device

[0040] like figure 1As shown, the suction combined electrochemical micro-additive device includes a sealed electrolytic cell 1, a liquid storage tank 2, a substrate 3, an electrochemical workstation 4, a nozzle, an electrode, a pump and a three-dimensional translation platform 9, and the substrate 3 is fixed on the three-dimensional displacement stage 9, and the electrodes include a reference electrode 10, a counter electrode 11 and a working electrode with the substrate 3 as electrodes arranged in the sealed electrolytic cell 1, the reference electrode 10, the counter electrode 11 and the The working electrodes are all electrically connected to the electrochemical workstation 4 (that is, the reference electrode 10, the counter electrode 11, and the working electrode are electrically connected to the reference electrode clip, the counter electrode clip, and the working electrode clip of the electrochem...

Embodiment 2

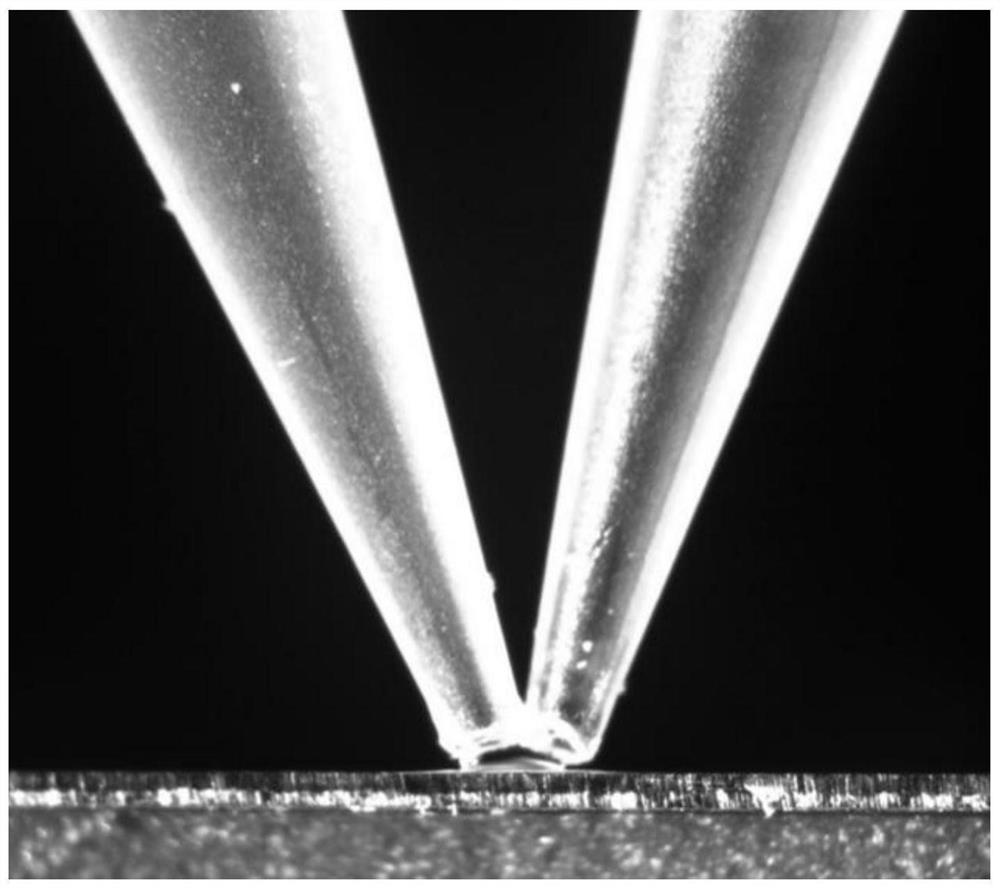

[0044] Example 2 A method for preparing a suction-combined electrochemical micro-additive material using DC voltage

[0045] Using the additive device of Example 1, the preparation method of this example specifically includes the following steps:

[0046] (1) Cut the polished copper sheet to a size of 3cm×3cm as the substrate 3, paste it on the glass sheet and place it on the XY plane of the three-dimensional translation stage 9, and connect it to the working electrode clamp of the electrochemical workstation 4.

[0047] (2) Fill 2 / 3 of the electrolyte in the sealed electrolytic cell 1, insert the reference electrode 10, the counter electrode 11, and the inlet and outlet conduit 12 and then tighten the cover to ensure tightness. The reference electrode 10 and the counter electrode 11 are respectively connected to the electrochemical The reference electrode clamp and the counter electrode clamp of the workstation 4 are first connected with the liquid storage tank 2, the No. 1 p...

Embodiment 3

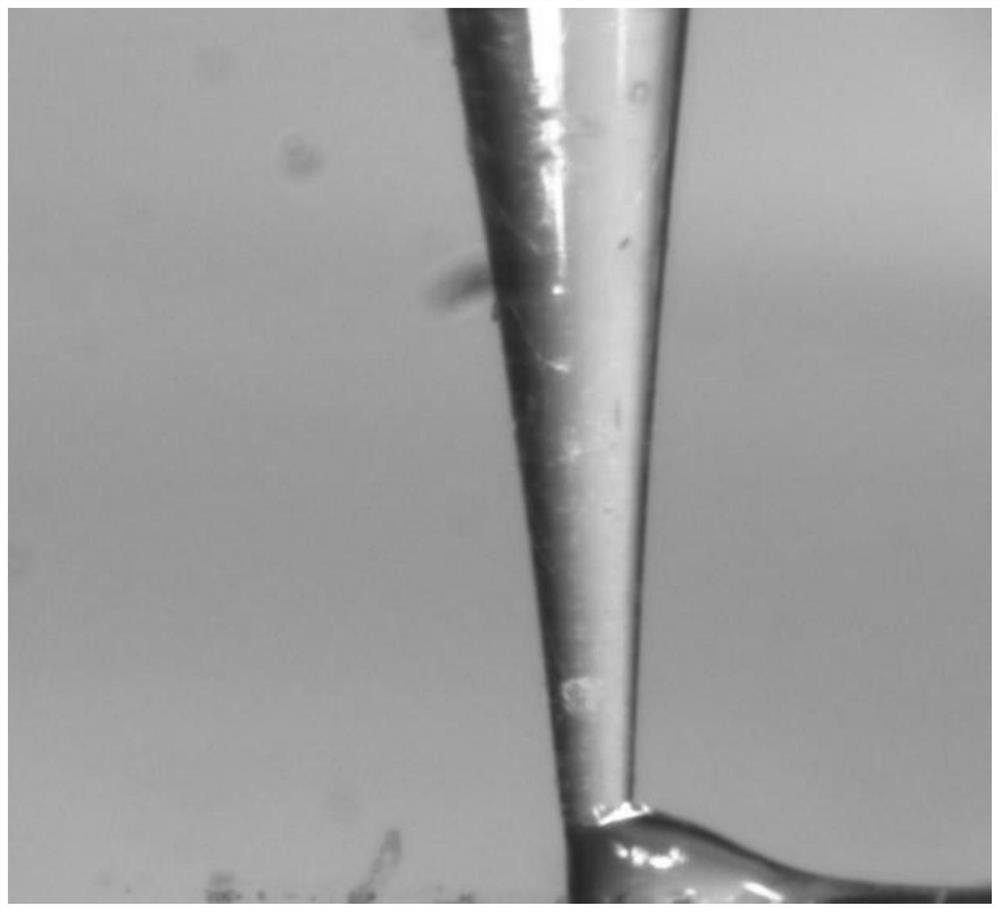

[0052] Example 3 A preparation method of pumping combined electrochemical micro-addition using pulse voltage

[0053] Using the additive device of Example 1, the preparation method of this example specifically includes the following steps:

[0054] (1) Cut the insulated PET plate on which the Cu seed layer with a thickness of 150nm was evaporated to a size of 3cm × 3cm as the substrate 3, paste it on the glass slide and place it on the XY plane of the three-dimensional displacement stage 9, and connect the electrochemical workstation 4 Working electrode clip.

[0055] (2) Fill 2 / 3 of the electrolyte in the sealed electrolytic cell 1, insert the reference electrode 10, the counter electrode 11, and the inlet and outlet conduit 12 and then tighten the cover to ensure tightness. The reference electrode 10 and the counter electrode 11 are respectively connected to the electrochemical The reference electrode clamp and the counter electrode clamp of the workstation 4 are first conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com