Adsorption array and cryogenic pump with adsorption array

A cryogenic plate and adsorption material technology, applied in pumps, liquid displacement machines, machines/engines, etc., can solve the problems of not being able to directly and quickly reach the adsorption material and affect the pumping speed, so as to improve the pumping speed, improve performance, The effect of increasing the adhesion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

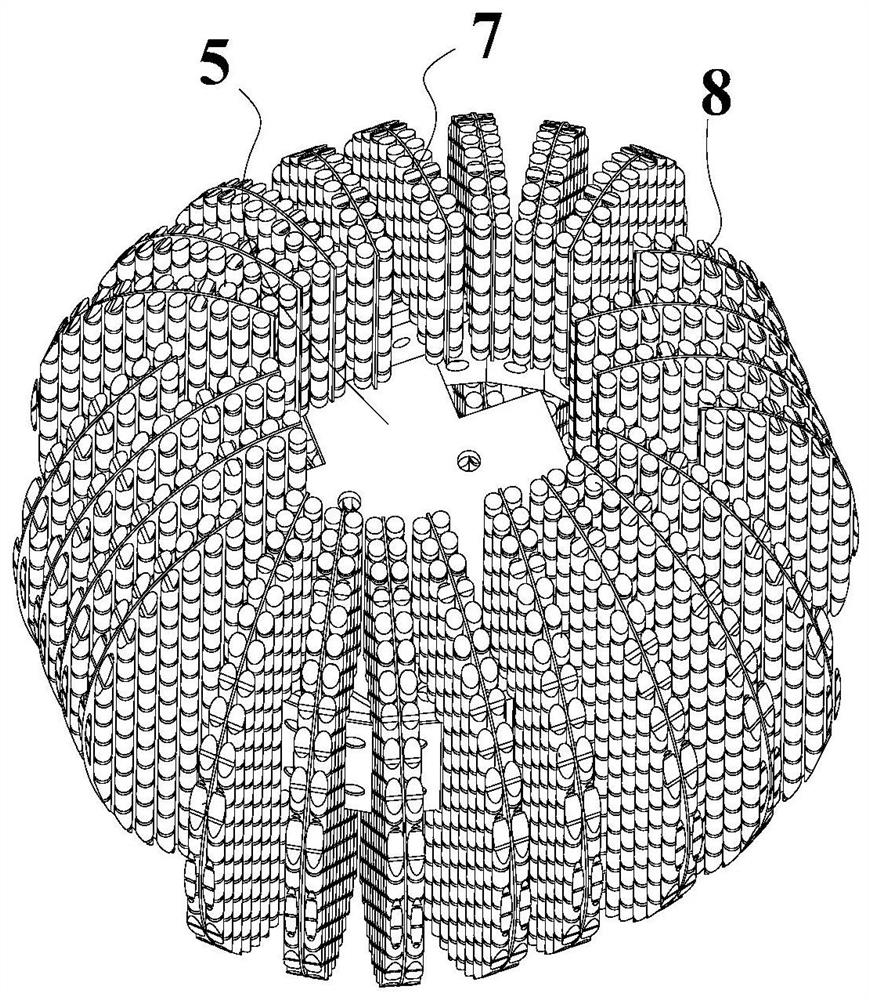

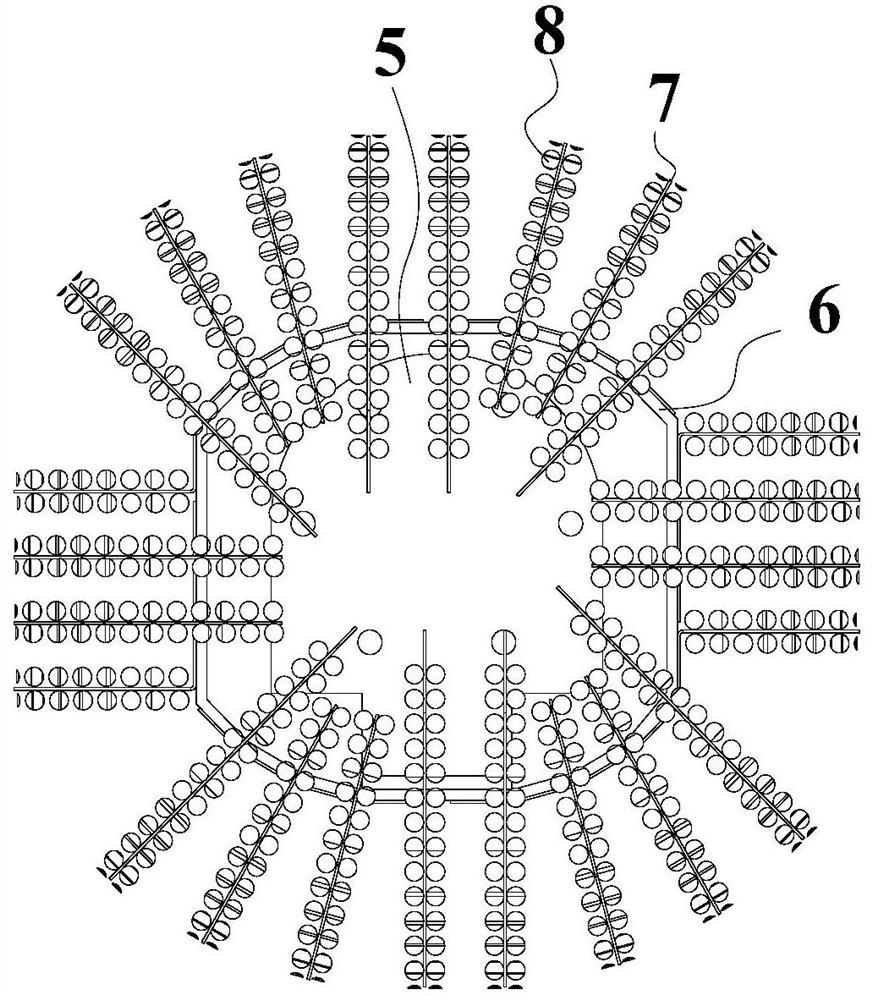

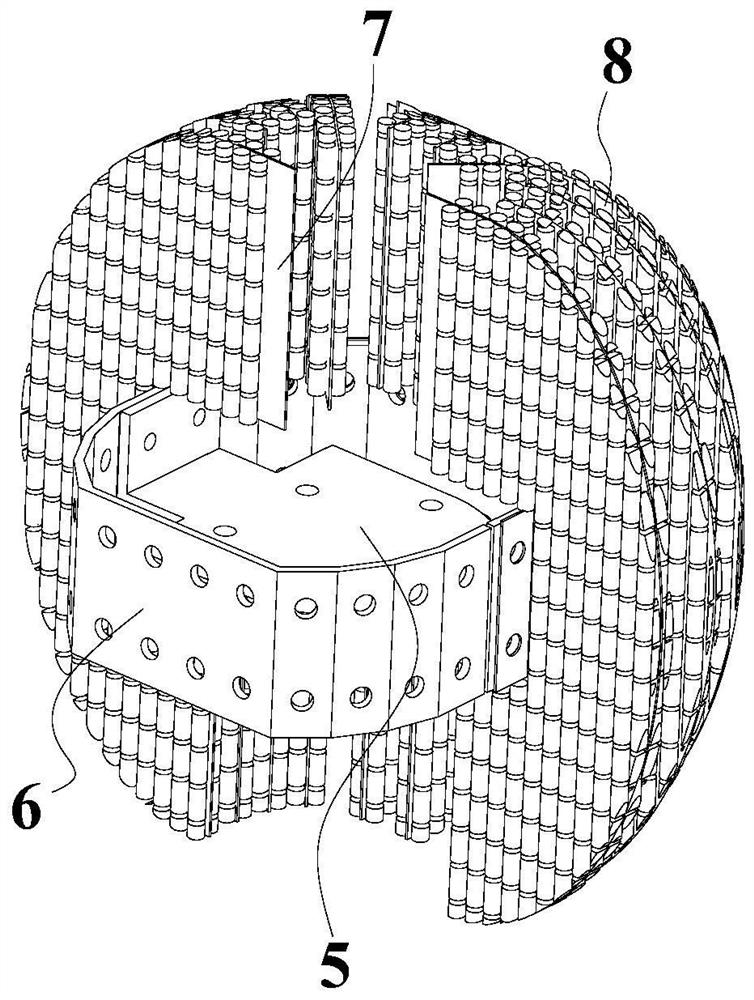

[0050] like figure 1 , 2 As shown, an adsorption array includes a connection plate 5 , a heat transfer plate 6 , a cryogenic plate 7 , and an adsorption material 8 .

[0051] like Figure 5 As shown, the heat transfer plate 6 is annular, and the inside of the heat transfer plate 6 is provided with a connection plate 5, and the surface of the heat transfer plate 6 is perpendicular to the connection plate 5; Figure 1-3 As shown, several low-temperature panels 7 are arranged on the outer surface of the heat transfer plate 6, all the low-temperature panels 7 are perpendicular to the connecting plate 5, and the low-temperature panels 7 are perpendicular to the surface of the heat transfer plate 6 where they are located. The inner side of the cryopanel 7 faces the inside of the heat transfer plate 6, and the outer contour of the cryopanel 7 is arc-shaped; further, the outer contours of all the cryopanels 7 are located on the same virtual spherical surface, and the cryopanel 7 is ...

Embodiment 2

[0064] like Figure 12 , 13As shown, a cryopump includes the above-mentioned adsorption array, and also includes a refrigerator 1 , a casing 2 , a radiation cold shield 3 , and a baffle 4 .

[0065] like Figure 12 , 13 As shown, the primary cooling stage 11 and the secondary cooling stage 12 of the refrigerator 1 are located in the casing 2 . In this embodiment, the low-temperature cold source adopts a G-M refrigerator, which has the characteristics of simple structure, low frequency, and few low-temperature moving parts. The refrigerator adopts bipolar refrigeration, which has a primary cooling stage 11 with a first cooling temperature and a secondary cooling stage 12 with a second cooling temperature. The primary cooling stage 11 is cooled to 65-100K, and the secondary cooling stage 12 is cooled to 10-15K.

[0066] The shell 2 is a cylindrical first shell, the bottom of the first shell is a spherically raised bottom, a horizontal cylinder is arranged on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com