A kind of rolling saggar rolling progressive mechanism and rolling progressive method

A technology for a rotary drive mechanism and a saggar is applied in the field of high-temperature sintering furnaces, which can solve the problems of the uncontrolled rotation speed of the sagger, reduce the reliability of the whole machine, reduce the reliability and life of the whole machine, etc. Gear occlusion failure, rich effects applicable to scenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

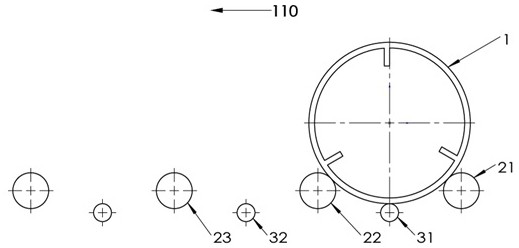

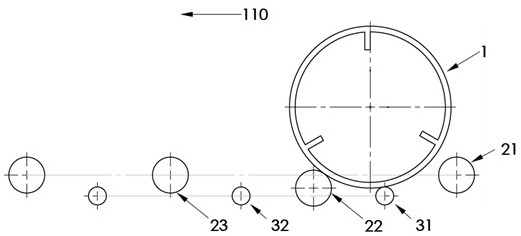

[0037] The present embodiment provides a rolling sagger tumbling and advancing mechanism. like figure 1 Shown is a schematic cross-sectional view of the first rolling saggar tumbling and advancing mechanism of the present invention in the first state, which includes a saggar 1, three equidistantly spaced elevating wheels and two equidistantly spaced supporters wheel. The lifting wheel and the supporting wheel are cylindrical bodies made of ceramic materials. The outer contour of the saggar 1 is a cylinder. The axes of the lifting wheel, the supporting wheel and the saggar 1 are parallel to each other in three-dimensional space.

[0038] The lift wheels include a first lift wheel 21 , a second lift wheel 22 and a third lift wheel 23 . The supporting roller includes a first supporting roller 31 and a second supporting roller 32 . The above-mentioned lifting wheels and supporting wheels are arranged at intervals, that is, there is a lifting wheel between every two supporting...

Embodiment 2

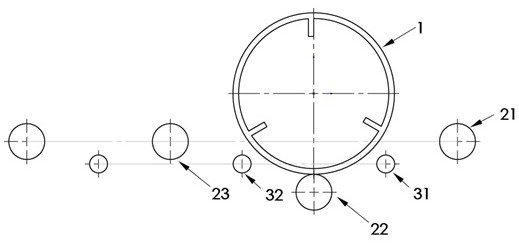

[0048] Image 6 Shown is a schematic cross-sectional view of another rolling saggar tumbling and advancing mechanism provided by an embodiment of the present invention, including: a saggar 1 , a first lifting wheel 21 , a second lifting wheel 22 , and a third lifting wheel 23 . The lifting wheel is a cylinder made of ceramic material. The outer contour of the saggar 1 is a cylinder. The axes of the lifting wheel and the saggar 1 are parallel to each other in three-dimensional space. The distance between the axes of two adjacent lifting wheels is smaller than the radius of the cross section of the outer contour of the saggar 1 . The outer contour of the saggar 1 is tangent to the two adjacent lifting wheels for support. Each lifting wheel is connected with an independent lifting mechanism (not shown in the figure) so that each lifting wheel can be lifted and lowered independently in the vertical direction. And each lift wheel is also connected with an independent rotary dri...

Embodiment 3

[0056] Except for the following description, the tumbling and advancing method of the tumbling and advancing mechanism of the rolling sagger provided in this embodiment is the same as that of the second embodiment. In the third state, while the third lifting wheel 23 descends, the second lifting wheel 22 rises. Under the combined action of gravity and the rising thrust of the second lifting wheel 22, the saggar 1 rolls in the forward direction 110, during which the saggar 1 rolls over. , the second lift wheel 22 and the third lift wheel 23 remain tangent. When the heights of the third lifting wheel 23 and the second lifting wheel 22 are the same, the Figure 9 the fourth state shown. The third lifting wheel 23 does not continue to descend, but turns to rise in synchronization with the second lifting wheel 22, and finally reaches the fifth state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com