Light composite insulation board flatness detection device and detection method

A technology of composite insulation and detection device, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of affecting the detection results, fixing the insulation board, and unable to meet the work needs of modern people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

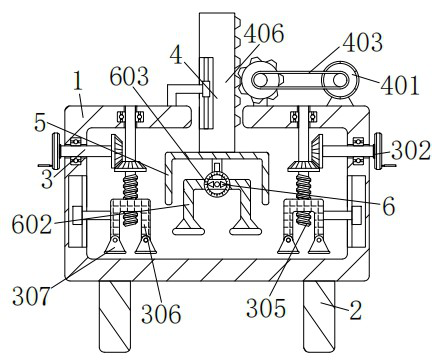

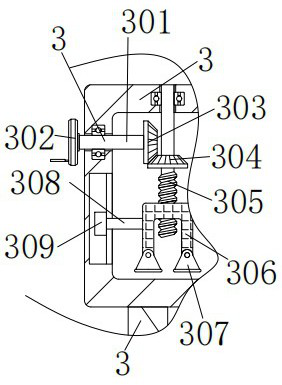

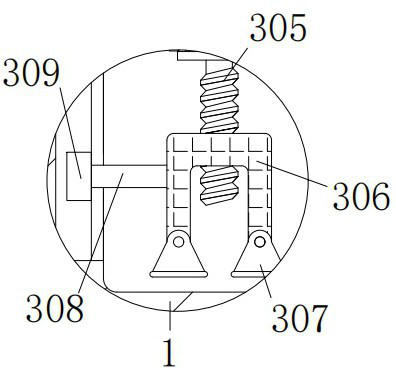

[0032] A light-weight composite thermal insulation plate flatness detection device, including a first shell 1 and a pillar 2, the left and right sides of the bottom of the first shell 1 are provided with pillars 2, the front of the first shell 1 is an open design, two pillars The top of 2 is fixedly connected with the bottom of the first housing 1, and the left and right sides of the inner wall of the first housing 1 are provided with a fixing device 3, and the fixing device 3 includes a cross bar 301, a handle 302, a first bevel gear 303, a second bevel gear Shaped gear 304, screw rod 305, the first curved plate 306, trapezoidal block 307, cross plate 308 and slide block 309, the outer wall left side of cross bar 301 is connected with the upper left side of first shell 1 by bearing rotation, and cross bar 301 can be Through bearing rotation, the left side of cross bar 301 is fixedly connected with the right side of handle 302, handle 302 can rotate cross bar 301 conveniently, ...

Embodiment 2

[0034] As an option, see figure 1 , 4And 5, the flatness detection device of light composite thermal insulation board, the top of the first shell 1 is provided with lifting device 4, and lifting device 4 comprises motor 401, first sheave 402, belt 403, second sheave 404, gear 405, The rack 406, the slide bar 407, the sliding sleeve 408 and the second bent plate 409, the model of the motor 401 is ECMA-E11320RS, the bottom of the motor 401 is fixedly connected with the top right side of the first shell 1 through the bracket, the output end of the motor 401 Fixedly connected with the rear end face of the first sheave 402, the output end of the motor 401 can drive the first sheave 402 to rotate, and the outer wall of the first sheave 402 is connected with the second sheave 404 through the belt 403, and the first sheave 402 When rotating, the second sheave 404 can be driven to rotate by the belt 403, the rear end surface of the second sheave 404 is fixedly connected with the front...

Embodiment 3

[0037] As an option, see figure 1 and 6 , the flatness detection device of light-weight composite insulation board, the inside of the second housing 5 is provided with a measuring device 6, the measuring device 6 includes a wide plate 601, a curved plate 602, a dial 603 and a slant plate 604, the top of the wide plate 601 is connected to the second The top of the inner wall of the second shell 5 is fixedly connected. An arrow is arranged on the front of the wide plate 601, so that the test results can be observed more intuitively. The bottom of the wide plate 601 is connected with a curved plate 602 through the rotation of the pin shaft, and the curved plate 602 can be rotated through the pin shaft. , the front of the curved plate 602 is provided with a dial 603, the top of the dial 603 is fixedly connected with a slant plate 604, and the top of the rear end of the slant plate 604 is fixedly connected with the front of the wide plate 601.

[0038] The solution in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com