Pressure sensing intelligent fabric and preparation method and application thereof

A pressure and intelligent technology, applied in the direction of fluid pressure measurement, measurement force, and instrument by changing ohmic resistance, can solve the problems of poor air permeability and flexibility of smart fabrics, inability to wash and care, and smart fabrics without wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

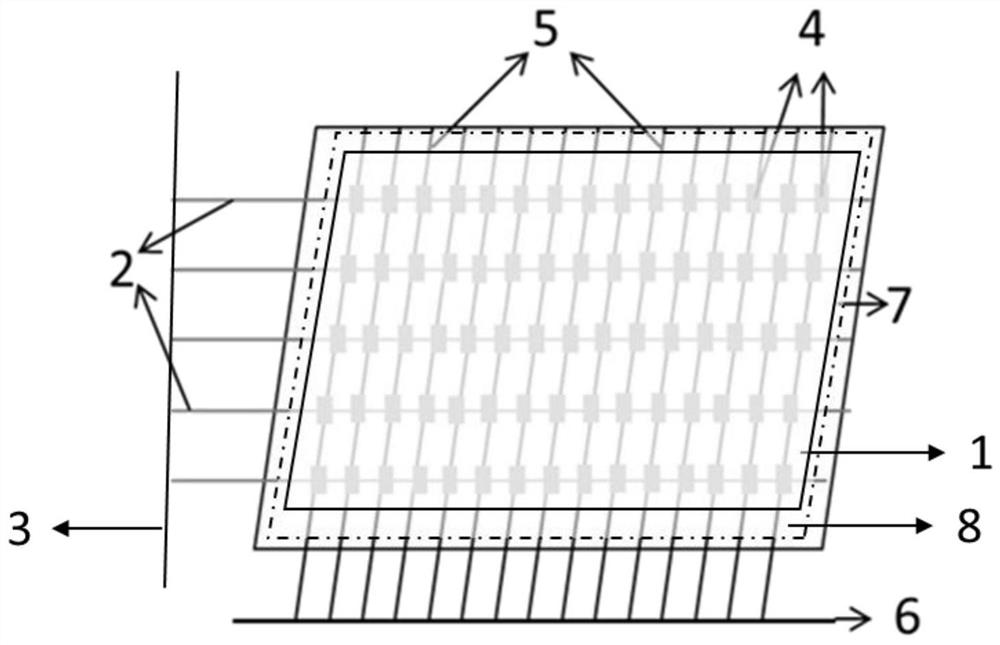

[0051] The present invention provides a method for preparing a pressure-sensing smart fabric described in the above technical solution, comprising the following steps:

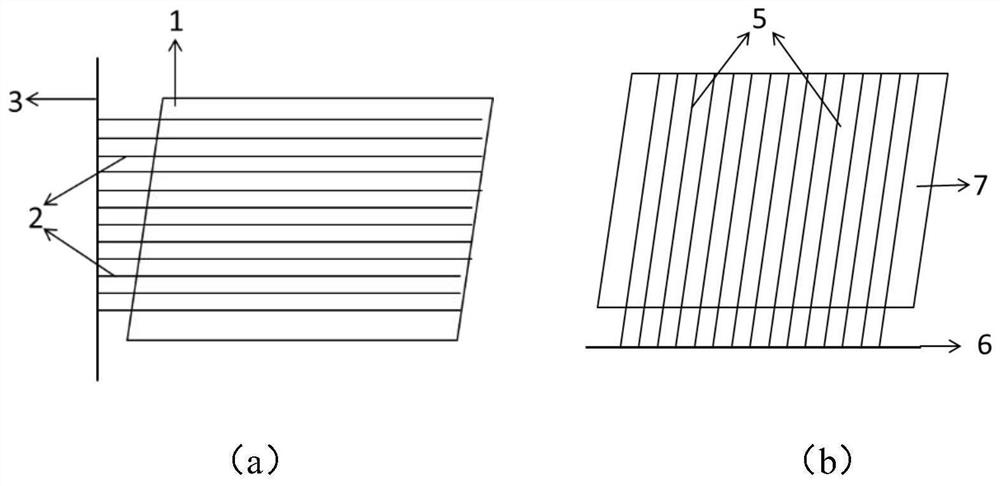

[0052] fixing a plurality of first conductive yarns to the inner surface of the first flexible fabric base layer;

[0053] fixing a plurality of second conductive yarns to the inner surface of the second flexible fabric base layer;

[0054] fixing the pressure-sensitive material on the first conductive yarn and / or the second conductive yarn in the form of strips or dots;

[0055] positioning the flexible fabric base layer with the conductive yarns and the pressure sensitive material secured thereto and the flexible fabric base layer with the conductive yarns secured thereto such that the first conductive yarns and the second conductive yarns intersect and are secured together Arranged in a matrix, point-like pressure-sensitive materials are distributed on the intersection of the matrix;

[0056] The first co...

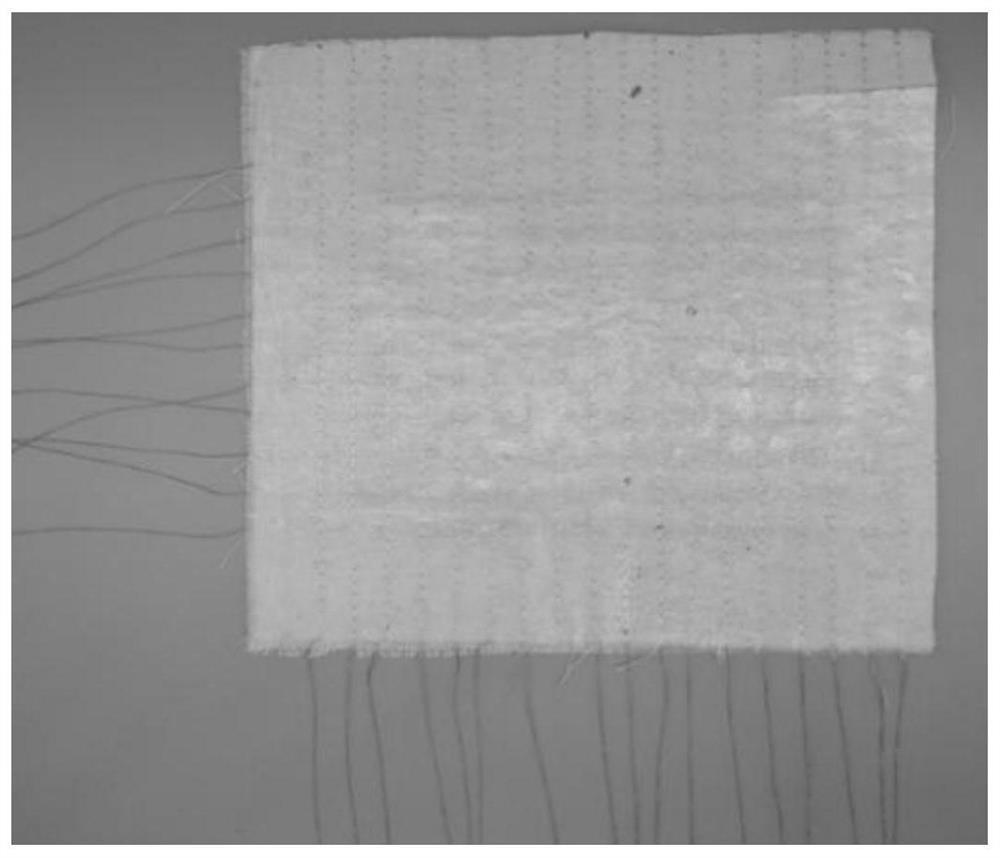

Embodiment 1

[0067] A pressure-sensing smart fabric, composed of the following materials:

[0068] The first flexible fabric base layer and the second flexible fabric base layer are pure cotton plain weave fabrics, and the mass per unit area of the fabric is 185g / m 2 , the warp and weft yarn densities are 24tex, the first flexible fabric base layer and the second flexible fabric base layer are subjected to flame-retardant and water-repellent finishing, and the composition of the flame-retardant and water-repellent treatment liquid is: organosilicon softener (amino silicone oil) 5wt% , resin crosslinking agent (triallyl isocyanurate) 2wt%, flame retardant (dimethylphenyl phosphate) 20wt%, fluorine-free water repellent (alkylamine and acrylate polymer) 3wt%, The rest is water; the method of flame-retardant and water-repellent finishing is as follows: the first flexible fabric base layer and the second flexible fabric base layer are placed in the flame-retardant and water-repellent treatmen...

Embodiment 2

[0076] A pressure-sensing smart fabric, composed of the following materials:

[0077] The first flexible fabric base layer and the second flexible fabric base layer are polyester-cotton blended plain weave fabrics, and the mass per unit area of the fabric is 115g / m 2 , the warp and weft yarn density is 520 / 10cm; the first flexible fabric base layer and the second flexible fabric base layer are subjected to flame-retardant and water-repellent finishing, and the composition of the flame-retardant and water-repellent treatment liquid is: organosilicon softener (amino Silicone oil) 3wt%, resin crosslinking agent (triallyl isocyanurate) 1wt%, flame retardant (xylyl phosphate) 15wt%, fluorine-free water repellent (alkylamine and acrylate polymer ) 1wt%, and the rest is water; the flame-retardant and water-repellent finishing method is as follows: the first flexible fabric base layer and the second flexible fabric base layer are respectively placed in the flame-retardant and water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com