Digital production line Internet of Things teaching system and management method and device thereof

A technology of the Internet of Things system and teaching system, which is applied in the field of intelligent manufacturing teaching, can solve the problems of lack and inability to train students

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

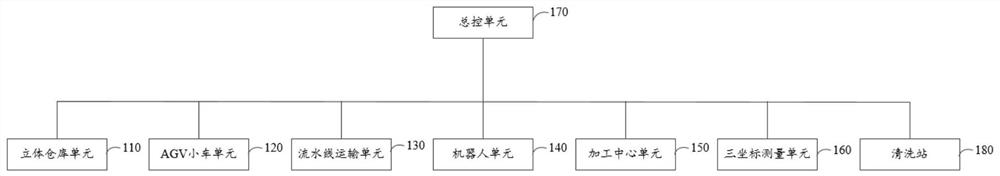

[0044] like figure 1 As shown, it is a structural block diagram of a digital production line Internet of Things system provided in the implementation of the present invention. In one embodiment, the digital production line Internet of Things system may specifically include:

[0045] Three-dimensional warehouse unit 110, AGV trolley unit 120, assembly line transportation unit 130, robot unit 140, machining center unit 150, three-coordinate measurement unit 160 and master control unit 170; said three-dimensional warehouse unit 110, said AGV trolley unit 120, all The assembly line transport unit 130, the robot unit 140, the machining center unit 150, and the three-coordinate measurement unit 160 are respectively connected to the master control unit 170 by communication;

[0046] The three-dimensional warehouse unit 110 is used to simulate intelligent material management;

[0047] The AGV trolley unit 120 is used to pick up materials from the three-dimensional warehouse unit 110 ...

Embodiment 2

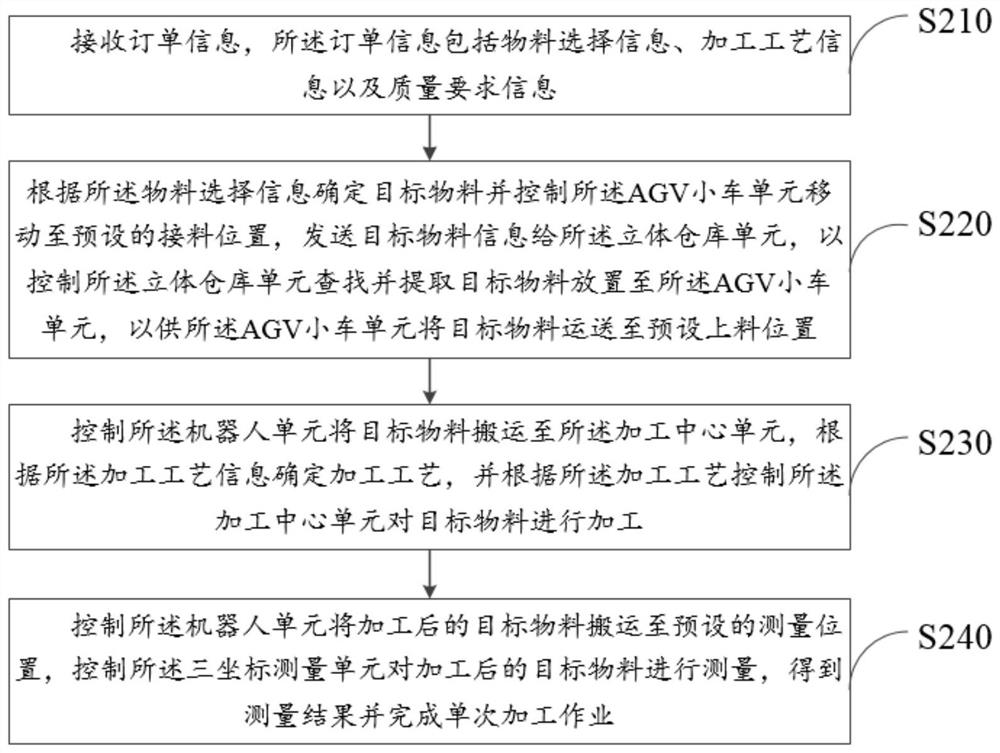

[0064] Such as figure 2 As shown, it is a flowchart of a digital production line Internet of Things system management method provided in the embodiment of the present invention. The digital production line Internet of Things system management method provided in the embodiment of the present invention is used to control and manage the digital production line Internet of Things system. Specifically include:

[0065] Step S210, receiving order information, said order information including material selection information, processing technology information and quality requirement information;

[0066] Step S220, determine the target material according to the material selection information and control the AGV trolley unit to move to the preset material receiving position, and send the target material information to the three-dimensional warehouse unit, so as to control the three-dimensional warehouse unit to search and extract the target material The material is placed on the AGV t...

Embodiment 3

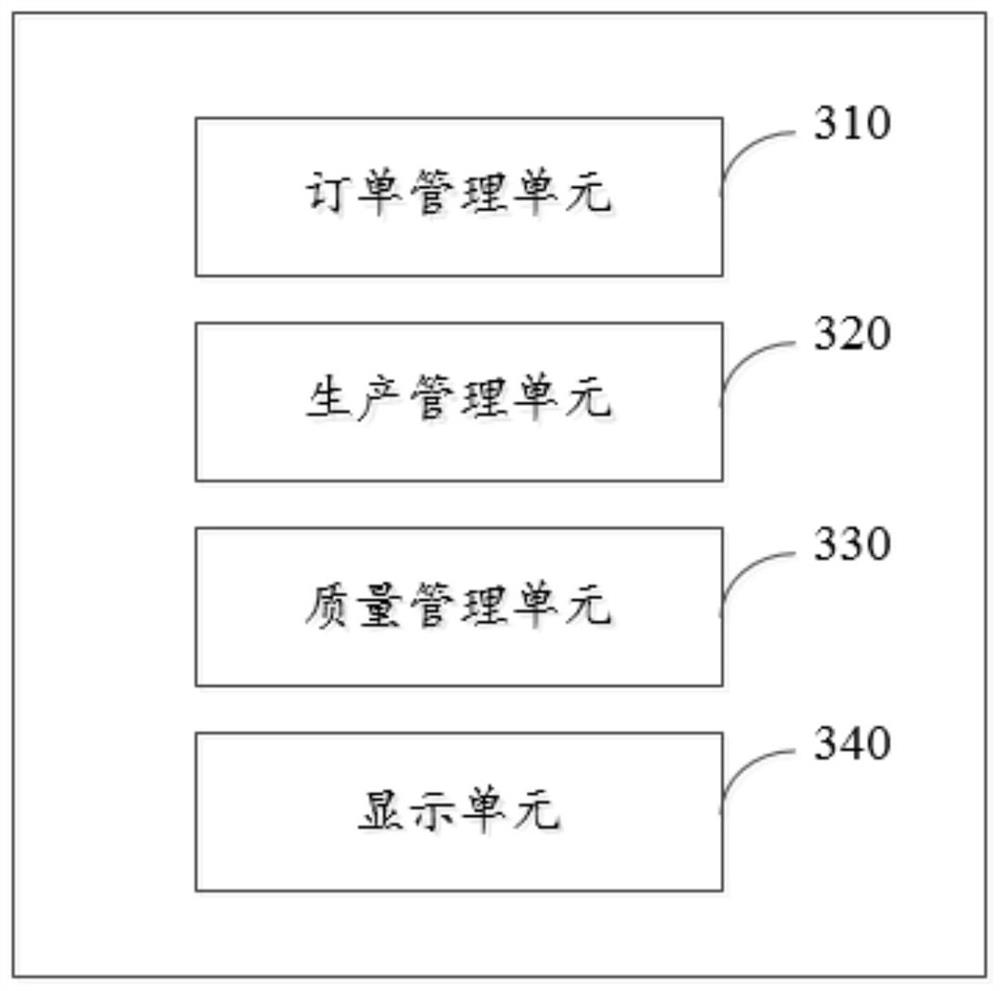

[0082] Such as image 3 As shown, it is a structural block diagram of a digital production line Internet of Things teaching system management device provided in the embodiment of the present invention. It should be noted that the management device in the embodiment of the present invention can inherit the master control unit described in the previous embodiment , some or all of the steps of the management method are performed. Specifically, a digital production line Internet of Things teaching system management device is used to control and manage the digital production line Internet of Things system, including:

[0083] The order management unit 310 is configured to receive order information, form an order report according to the order information, and perform order management according to the order report, and the order information includes material selection information, processing technology information and quality requirement information;

[0084] The production manageme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com