Locking and sealing connection structure for load-bearing cable

A technology for connecting structures and cables, applied in the direction of connections, connections, and parts of connecting devices where permanent deformation is active, it can solve problems such as affecting the construction process, low connection reliability, and long construction period, saving time and improving On-site operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

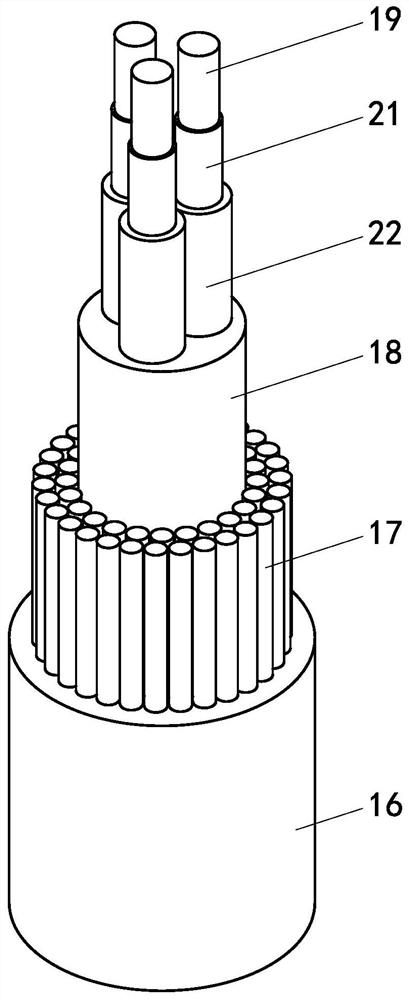

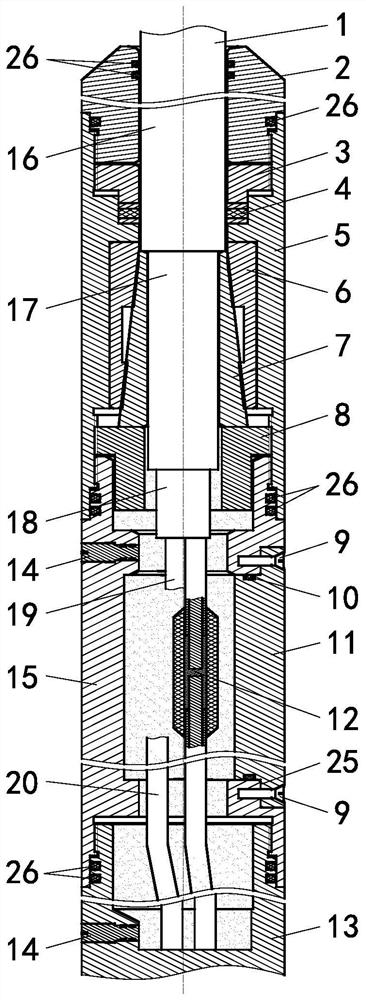

[0025] Push the load-carrying cable 1 into the figure 1 As shown, peel off layer by layer from top to bottom and from outside to inside. The outermost layer is an outer sheath 16, and the outer sheath 16 is composed of two layers of steel wires to form an armor layer 17. The armor layer 17 is provided with an inner sheath 18, and a group of copper wires 19 are arranged inside the inner sheath 18. The copper wires 19 An F46 insulating layer 22 is arranged on the outside, and a layer of polyimide film 21 is also arranged between the copper wire 19 and the F46 insulating layer 22 .

[0026] In this example, the figure 1 The load-bearing cable 1 shown is safely and reliably connected to the lead wire 20 on the instrument body 13 .

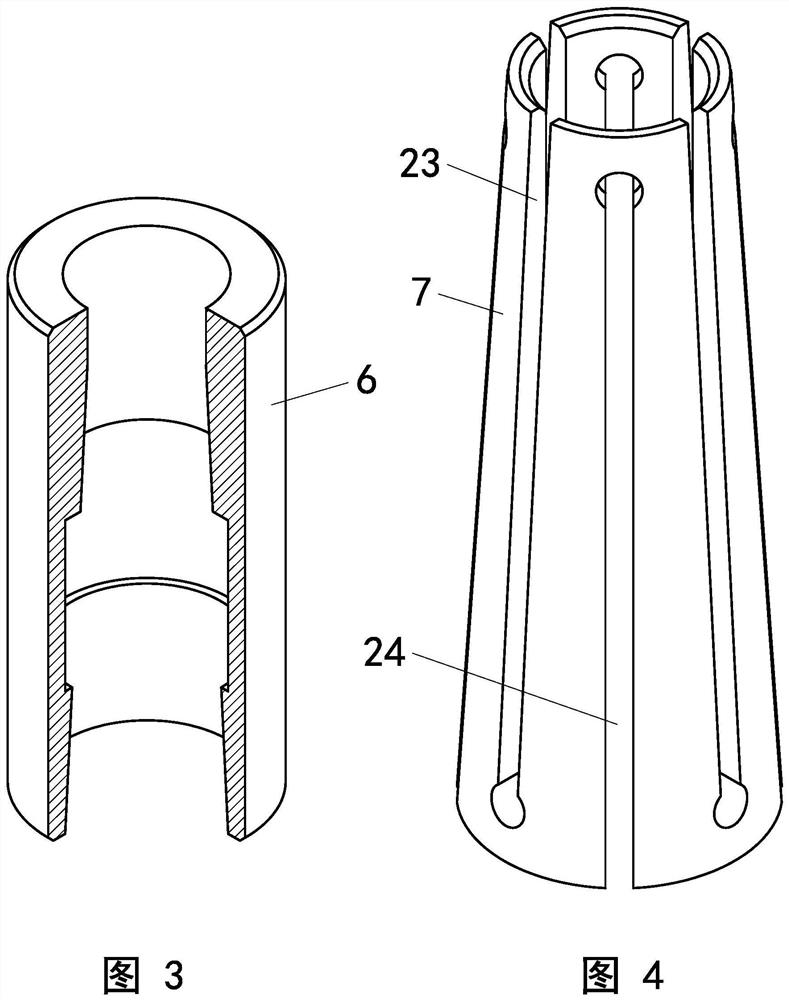

[0027] During specific implementation, first press the load-bearing cable 1 figure 1 Layers shown peeled away. Another example figure 2 As shown, put the weight 2, screw plug 3 and seal 4 on the stripped load-bearing cable 1 in sequence, insert t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com