Gas-roller conveying-type catalytic infrared heating peeling method for tomatoes

An infrared heating technology for tomatoes, applied in vegetable or fruit peeling, food science, application, etc., can solve problems such as poor heating uniformity, shortened processing time, unreasonable structural design, etc., to achieve uniform heating, shortened processing time, Promote high value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

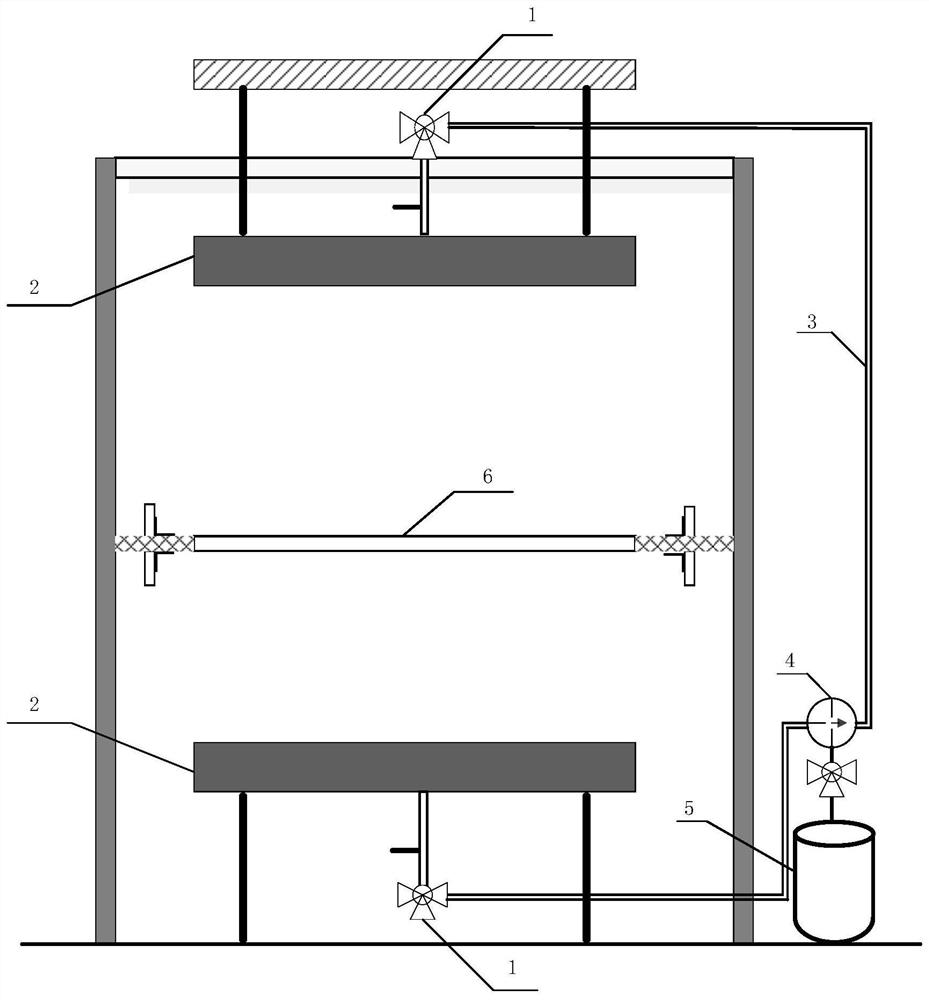

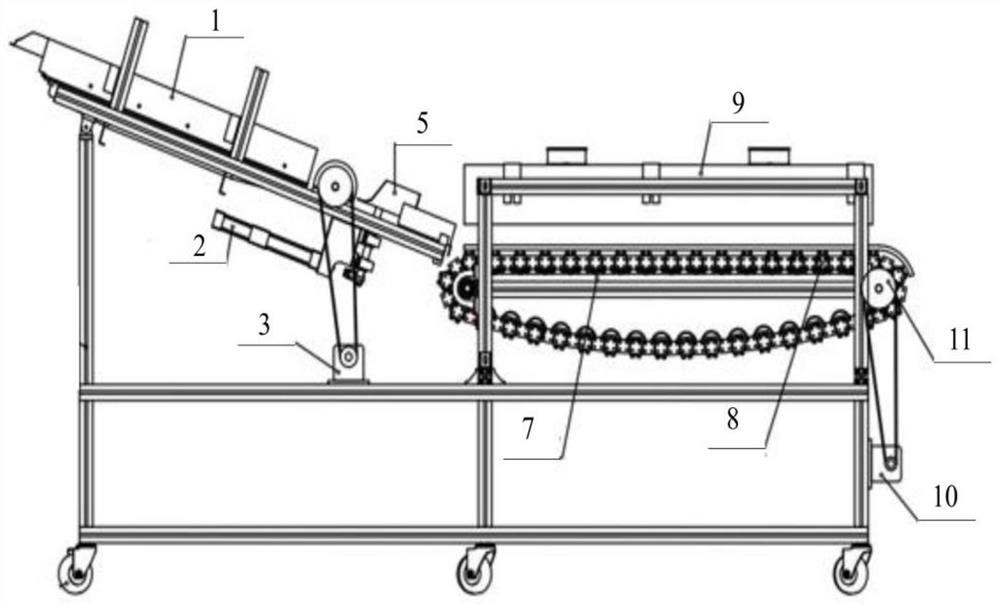

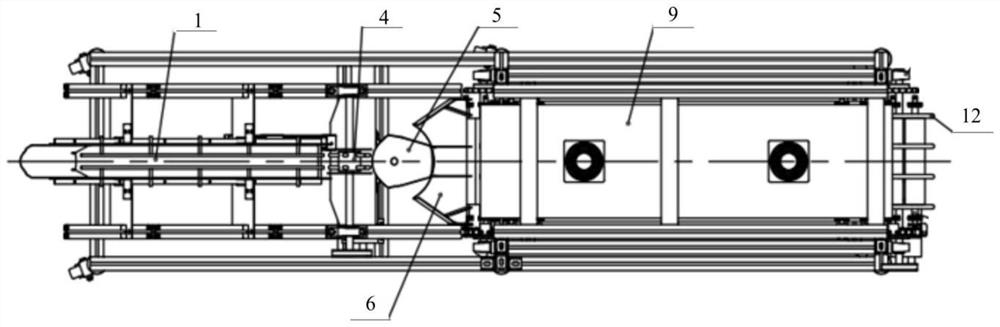

[0031] Embodiment 1: Gas-Roller Transmission Catalytic Infrared Heating Peeling

[0032]The gas-fired-roller transmission type catalytic infrared heating peeling method of fresh tomatoes is carried out according to the following steps:

[0033] (1) Turn on the button of the catalytic infrared generator to preheat the electric heating for 15 minutes, then turn off the electric heating, and turn on the liquefied gas valve to raise the temperature of the catalytic infrared panel to the set heating temperature of 350°C.

[0034] (2) Turn on the gas generator in the front section, let the tomatoes enter the combustion flame in order to be heated for 5 seconds; then through the reversing groove, let the tomatoes enter the three conveying roller chains in sequence, and then realize the tomato by the forward movement of the speed regulating motor and the rack. Tumbling forward at 360° on the conveyor roller chain, the tomatoes are heated at a catalytic infrared heating temperature of ...

Embodiment 2

[0042] The test treatment process is the same as in Example 1, except that the flame heating time is 10s. The specific results are shown in Table 1.

Embodiment 3

[0044] The test treatment process is the same as in Example 1, the difference being that the flame heating time is 15s, and the specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com