System for recycling waste materials and wastewater in concrete mixing plant

A waste water recovery and mixing station technology, applied in the direction of filtration circuit, filtration separation, separation method, etc., can solve the problems of low efficiency of waste water and waste treatment, achieve the effect of improving efficiency, increasing the contact area of the tank wall, and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

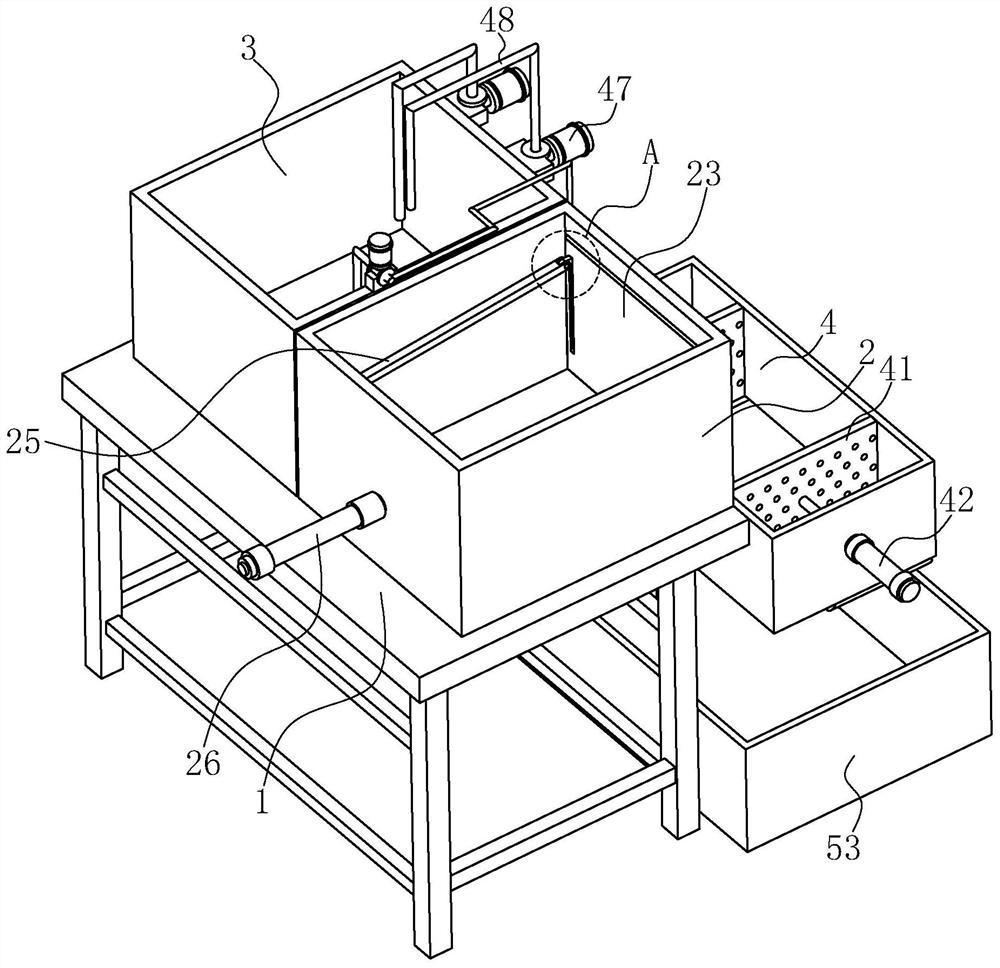

[0041] Contraction below Figure 1-8 Further detailed description of the present application.

[0042] The present application discloses a concrete mixing station wastewater recovery and utilization system. Refer figure 1 The wastewater recovery system includes a rack 1, a processing pool 2, and a collecting pool 3, a processing pool 2 and a collecting pool 3 are fixedly mounted on the rack 1, the treatment pool 2 and the collecting pool 3 are all open.

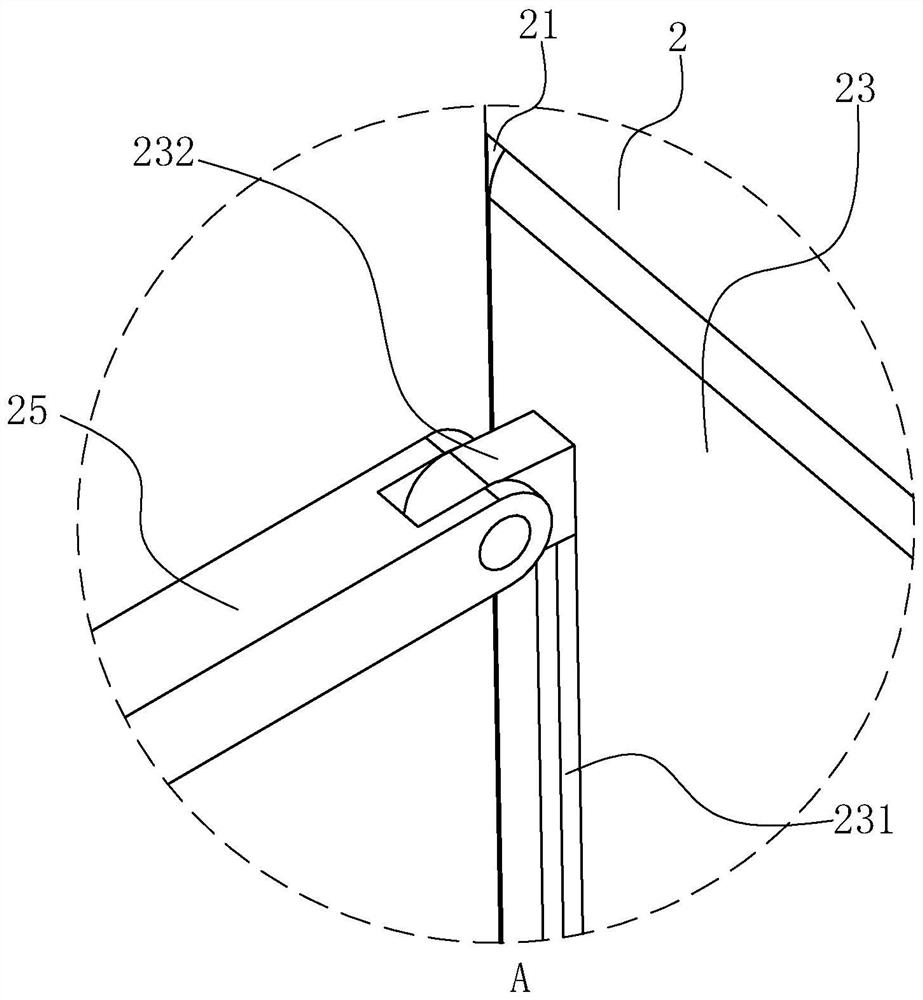

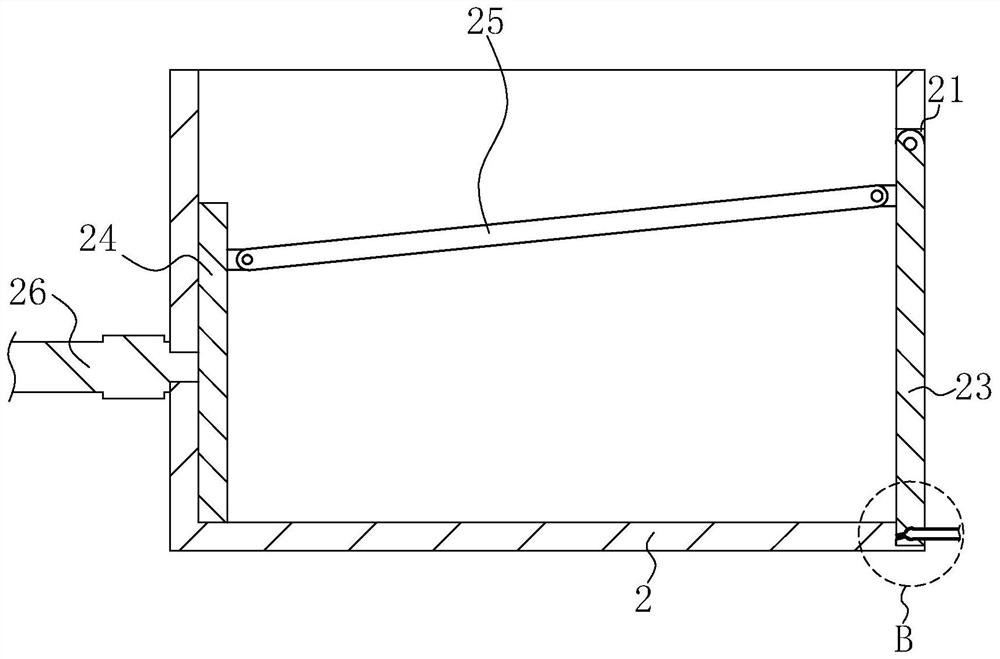

[0043] Refer figure 2 with image 3 The discharge port 21 is provided on one side of the processing pool 2, and the processing pool 2 is provided with a baffle 23, and one end of the baffle 23 is hinged at one end of the opening of the discharge port 21 close to the processing pool 2. The other end of the baffle 23 extends toward the other end of the discharge port 21, and the baffle 23 is connected to the hinge shaft connected to the horizontal direction and extends along the edge of the discharge port 21; the processing pool 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com