Design and construction method of T-shaped rectangular steel tube-corrugated steel plate composite wall

A technology of rectangular steel pipes and combined walls, which is applied in the direction of walls, building components, building types, etc., can solve the problems of complex structure of T-shaped shear wall-steel beam joints, difficult on-site connection of vertical components, and high overall cost, so as to improve Common work performance, reduction of fire protection coating area, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions provided by the present application will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present application will become clearer in conjunction with the following description.

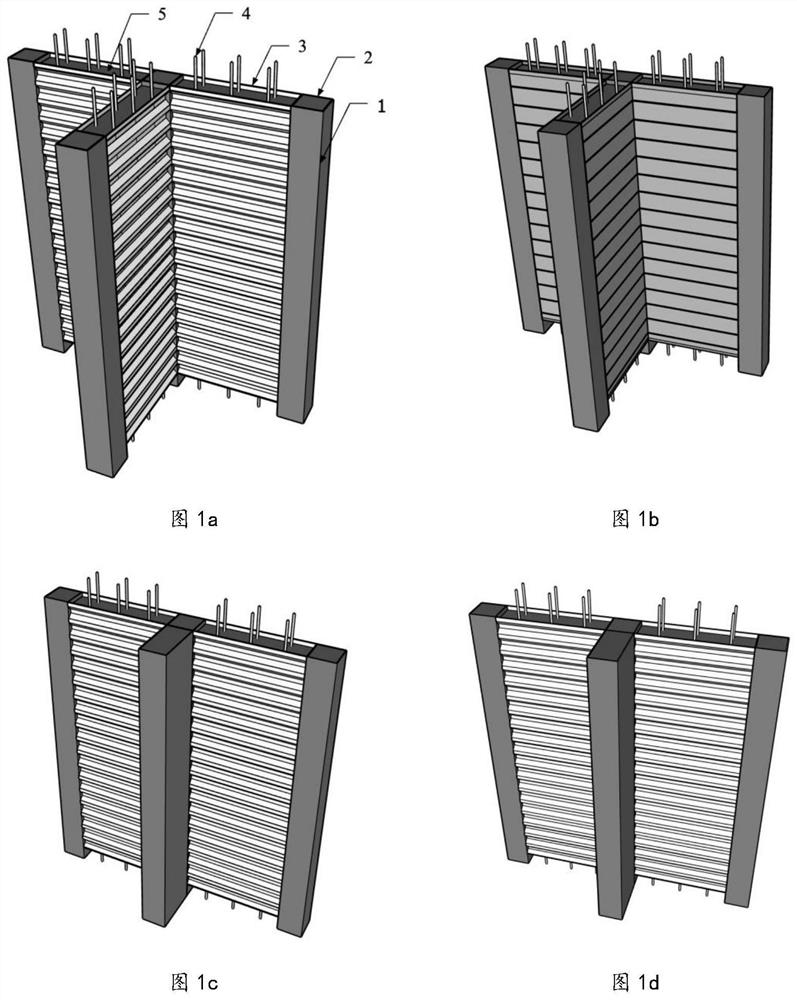

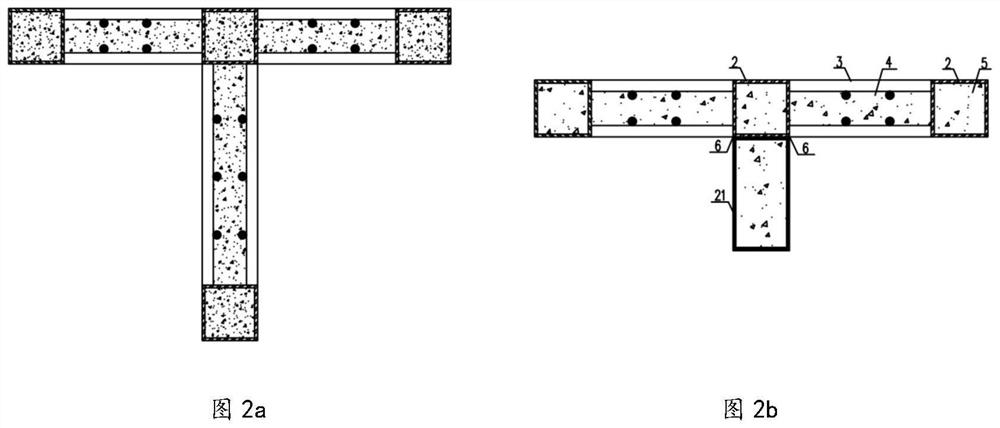

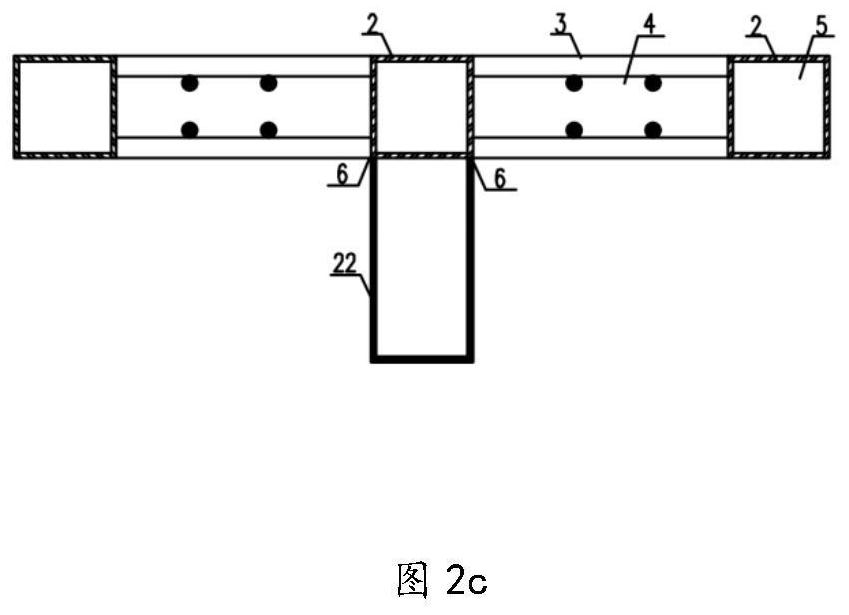

[0041] A method for designing and implementing a T-shaped rectangular steel pipe-corrugated steel plate composite wall (1), characterized in that:

[0042] Process 1: Factory prefabrication

[0043] In terms of composition, it includes a rectangular steel pipe column (2), a corrugated steel plate (3), and a steel mesh sheet (4), wherein: the rectangular steel pipe column (2) can be formed by cold bending or welded by steel plates; The end rectangular steel pipes (2) are connected by welds, and are placed horizontally along the corrugation, and the outermost sides of the crests are flush with the outer sides of the rectangular steel pipes; the steel mesh (4) is formed by spot welding or bind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com