In-situ leaching uranium mining well pattern and in-situ leaching uranium mining construction method

A technology of in-situ leaching for uranium mining and construction methods, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low return on investment, increase contact area, reduce labor intensity, and improve in-situ leaching efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] It should be noted that the "leach solution" in this application refers to the unreacted stock solution, and the "reaction solution" refers to the solution after the leach solution enters the ore layer 1 and reacts with the uranium-containing part therein.

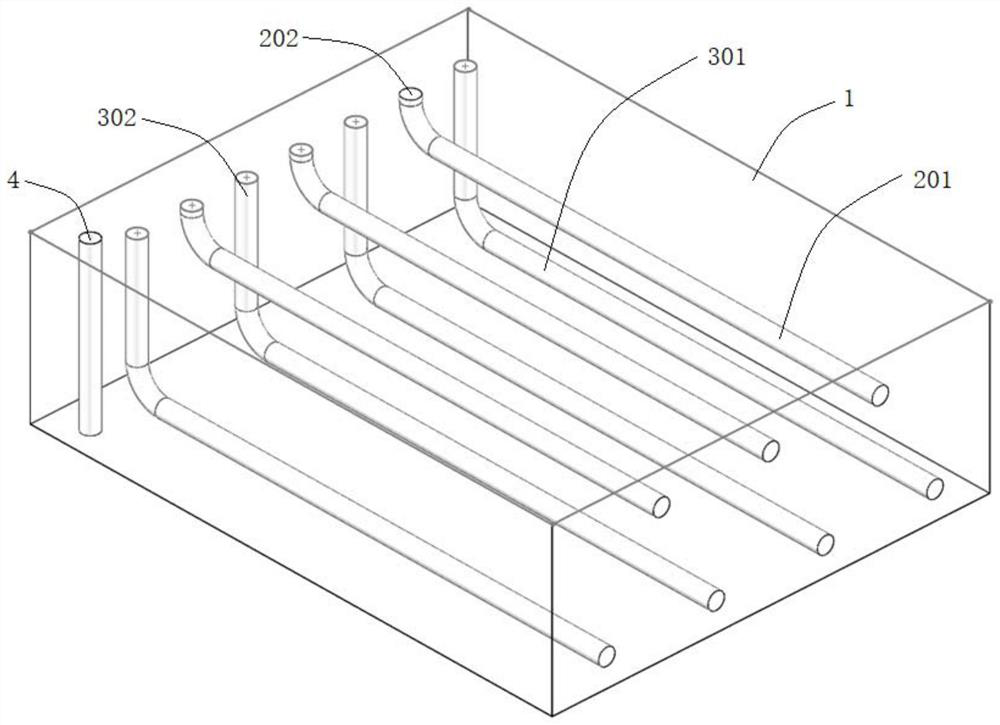

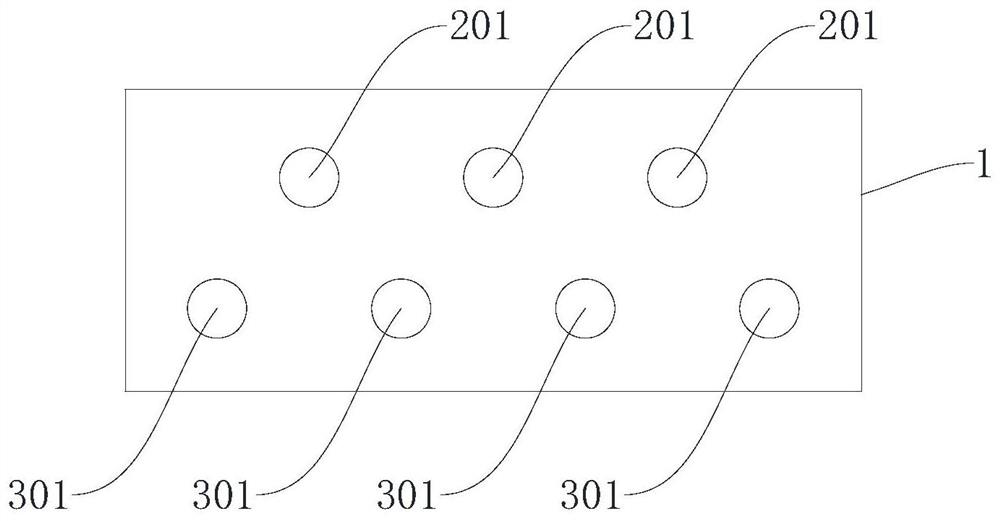

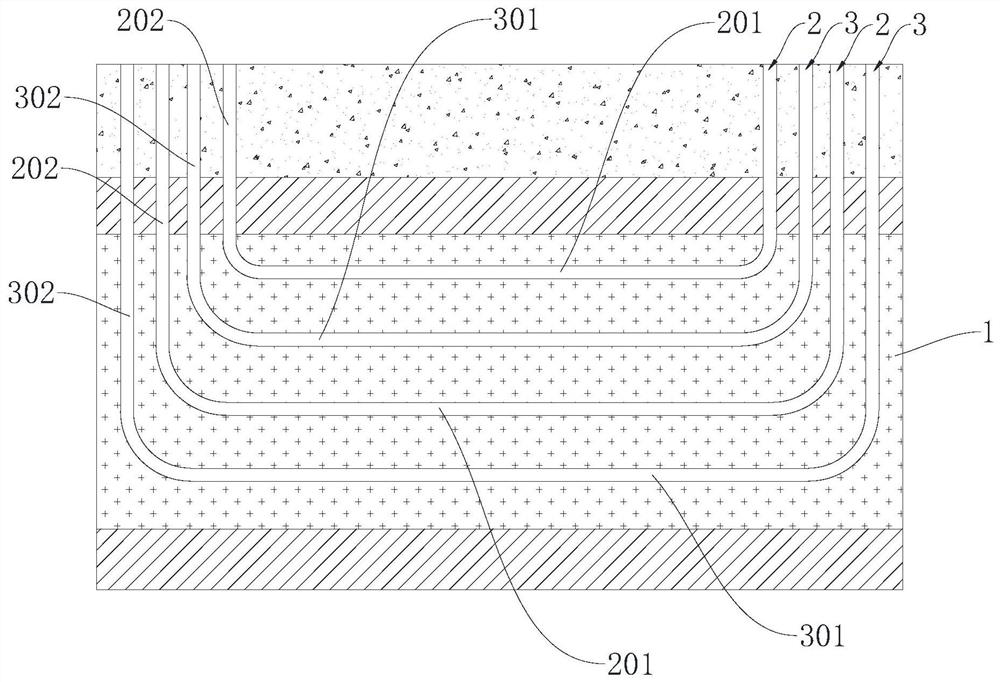

[0034] Please also refer to Figure 1 to Figure 4 , the in-situ leaching uranium mining well pattern provided by the present invention is now described. The in-situ leaching uranium well pattern includes a horizontal injection well group and a horizontal pumping well group, the horizontal liquid injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com