Water-cooled combustor and condensing boiler

A burner, water-cooled technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of burner surface blockage, reduction of boiler output, burner damage, etc., to reduce combustion intensity and improve combustion efficiency. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

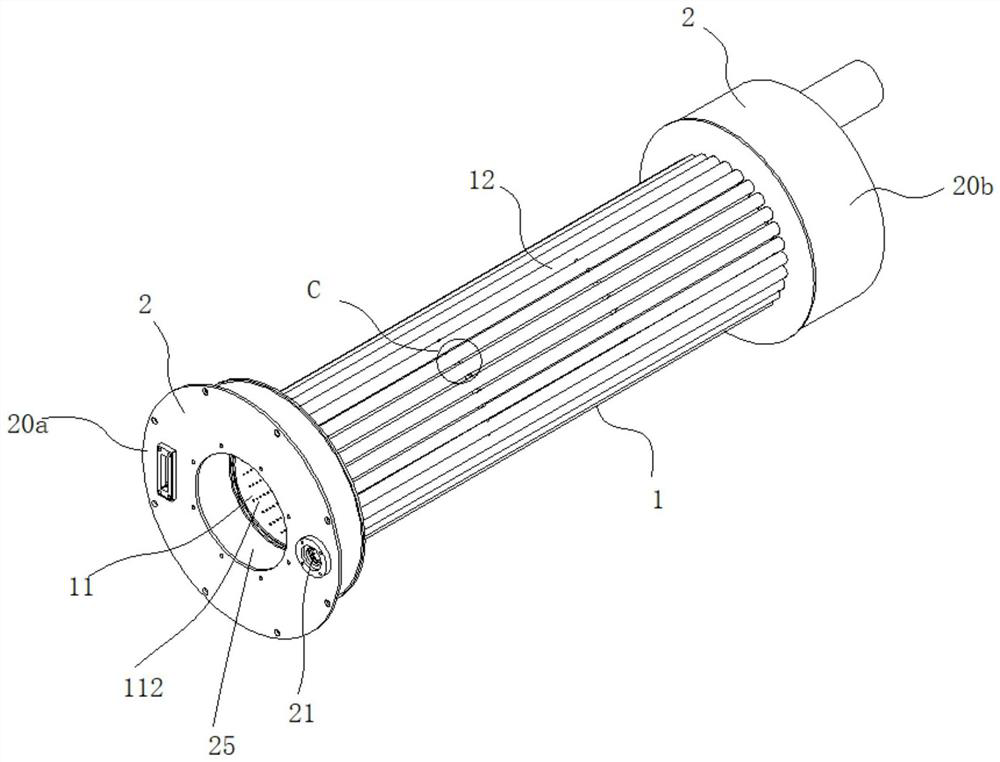

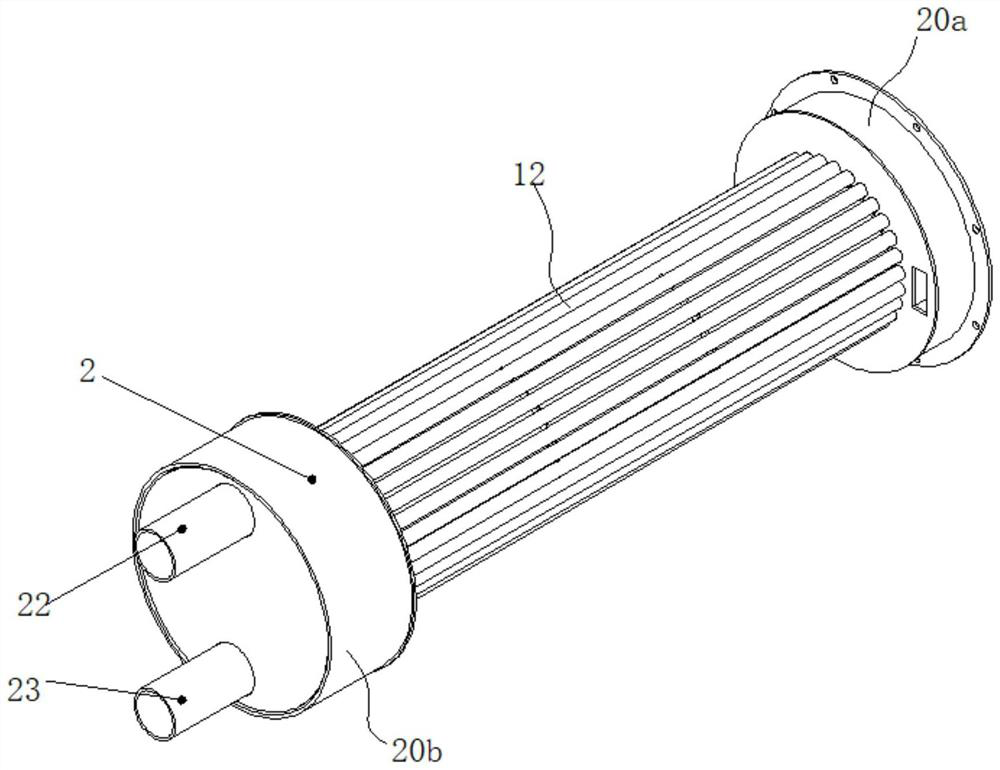

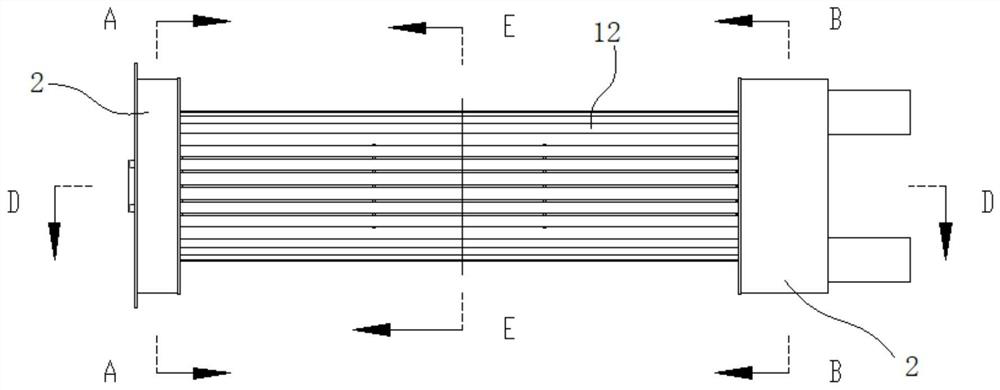

[0049]The present invention provides a water-cooled burner, which includes a tubular body 1 and a fluid box 2 connected to both ends of the tubular body 1. The tubular body 1 includes an inner tube 11 and a plurality of outer tubes 12 located outside the inner tube. .

[0050] The inner cylinder 11 extends along the central axis and has an inner surface and an outer surface. The inner surface forms a mixing chamber 112 , and the inner cylinder is provided with a plurality of rows of holes 111 .

[0051] The tube wall thickness of the inner tube 11 is 0.2-0.8mm, preferably, the tube wall thickness of the inner tube 11 is 0.8mm, and the inner diameter of the inner tube 11 will be reasonably matched according to the size of the furnace. In the example, the tube wall thickness of the inner cylinder 11 is 0.8mm, and the inner diameter of the inner cylinder 11 is 200mm.

[0052] The axial direction of the plurality of rows of holes 111 is consistent with the axial direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com