Self-adaptive multi-working-condition steel secondary energy generation amount dynamic prediction method

A technology for secondary energy and dynamic prediction, applied in prediction, nuclear methods, artificial life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

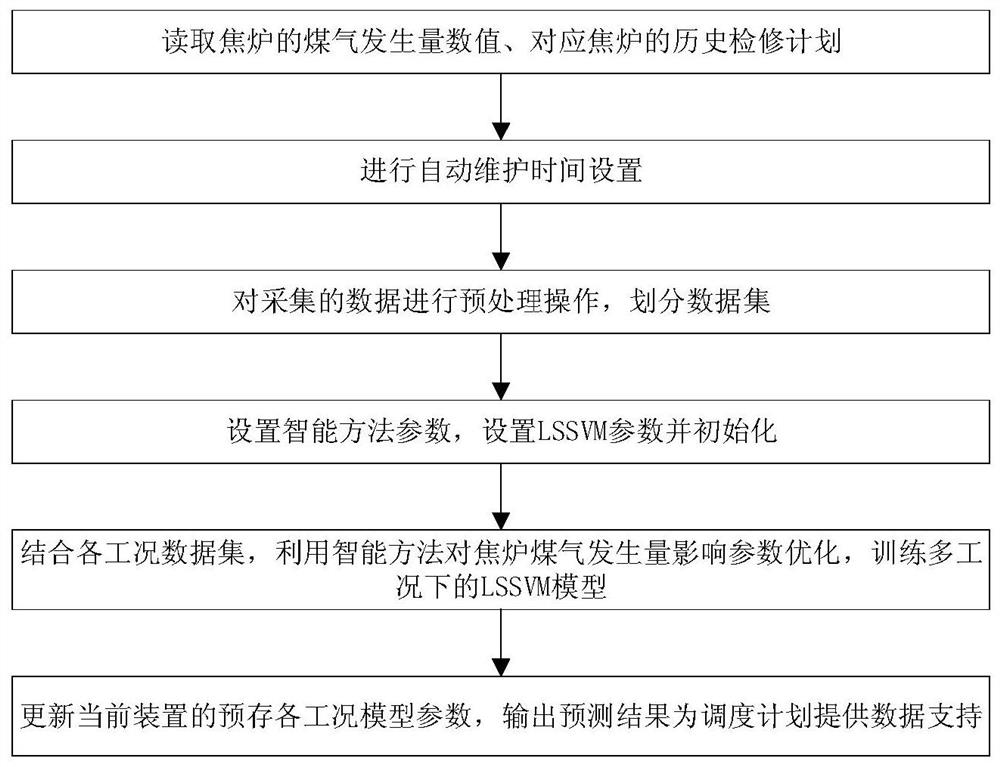

[0073] An adaptive multi-working-condition dynamic prediction method for secondary energy generation of steel, such as figure 1 shown, including the following steps:

[0074] Step 1: Obtain the historical data of coke oven gas generation under multiple working conditions; read the historical data of coke oven gas generation and the historical data of coke oven maintenance time, and ensure that the time steps are aligned. The working condition is marked and stored in the computer database;

[0075] Step 2: Set the coke oven gas generation data preprocessing time interval, read the system clock data, and enter the next step when the time interval is reached;

[0076] Step 3: Perform preprocessing operations on the collected coke oven gas generation data, and divide multi-working condition data sets;

[0077] Step 3.1: Perform data denoisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com