Device for treating hydrogen sulfide gas on underground coal roadway driving working surface through gas atomization alkaline fluid

A hydrogen sulfide and alkaline gas technology, which is applied in chemical instruments and methods, dispersed particle separation, earthwork drilling, etc. Simple structure, obvious governance effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

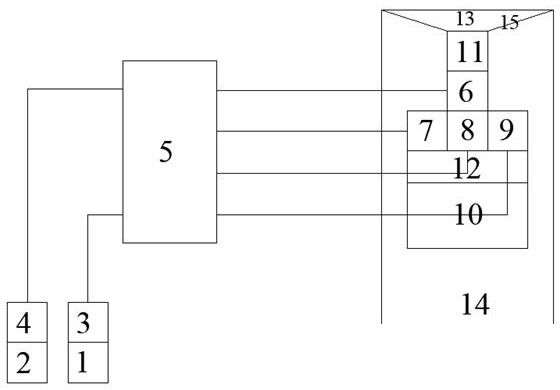

[0038] The hydrogen sulfide gas device for gas atomized alkaline fluid treatment of underground coal roadway driving face is characterized in that the device is composed of pressure air 1, pressure water-soluble alkaline liquid 2, pressure air pipeline 3, and pressure water-soluble alkaline liquid pipeline 4 , Treatment of hydrogen sulfide gas atomized alkaline fluid generator 5, the first alkaline aerosol nozzle group 6, the second alkaline aerosol nozzle 7, the third alkaline aerosol nozzle 8, the fourth alkaline aerosol nozzle 9, Coal roadway excavator 10, coal roadway excavator cutting head part 11, coal roadway excavator cutting head power part 12, coal wall and broken coal wall in the direction of excavation advance direction 13, coal wall of excavation roadway 14, hydrogen sulfide gas 15, etc. Composition; first, the pressure air 1 with a working pressure of 0.3Mpa is connected to the pressure air inlet on the lower left side of the hydrogen sulfide gas atomized alkaline...

Embodiment approach 2

[0053] The hydrogen sulfide gas device for gas atomized alkaline fluid treatment of underground coal roadway driving face is characterized in that the device is composed of pressure air 1, pressure water-soluble alkaline liquid 2, pressure air pipeline 3, and pressure water-soluble alkaline liquid pipeline 4 , Treatment of hydrogen sulfide gas atomized alkaline fluid generator 5, the first alkaline aerosol nozzle group 6, the second alkaline aerosol nozzle 7, the third alkaline aerosol nozzle 8, the fourth alkaline aerosol nozzle 9, Coal roadway excavator 10, coal roadway excavator cutting head part 11, coal roadway excavator cutting head power part 12, coal wall and broken coal wall in the direction of excavation advance direction 13, coal wall of excavation roadway 14, hydrogen sulfide gas 15, etc. Composition; first, the pressure air 1 with a working pressure of 0.5Mpa is connected to the pressure air inlet on the lower left side of the hydrogen sulfide gas atomized alkaline...

Embodiment approach 3

[0068] The hydrogen sulfide gas device for gas atomized alkaline fluid treatment of underground coal roadway driving face is characterized in that the device is composed of pressure air 1, pressure water-soluble alkaline liquid 2, pressure air pipeline 3, and pressure water-soluble alkaline liquid pipeline 4 , Treatment of hydrogen sulfide gas atomized alkaline fluid generator 5, the first alkaline aerosol nozzle group 6, the second alkaline aerosol nozzle 7, the third alkaline aerosol nozzle 8, the fourth alkaline aerosol nozzle 9, Coal roadway excavator 10, coal roadway excavator cutting head part 11, coal roadway excavator cutting head power part 12, coal wall and broken coal wall in the direction of excavation advance direction 13, coal wall of excavation roadway 14, hydrogen sulfide gas 15, etc. Composition; first, the pressure air 1 with a working pressure of 0.8Mpa is connected to the pressure air inlet on the lower left side of the hydrogen sulfide gas atomized alkaline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com