Welding device with dust and slag removal functions and application method thereof

A welding device and function technology, applied in the field of welding devices with dust removal and slag removal functions, can solve the problems of inability to purify smoke and dust, pollution of the working environment, inability to treat dust and slag, and achieve good practicability, increase efficiency, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

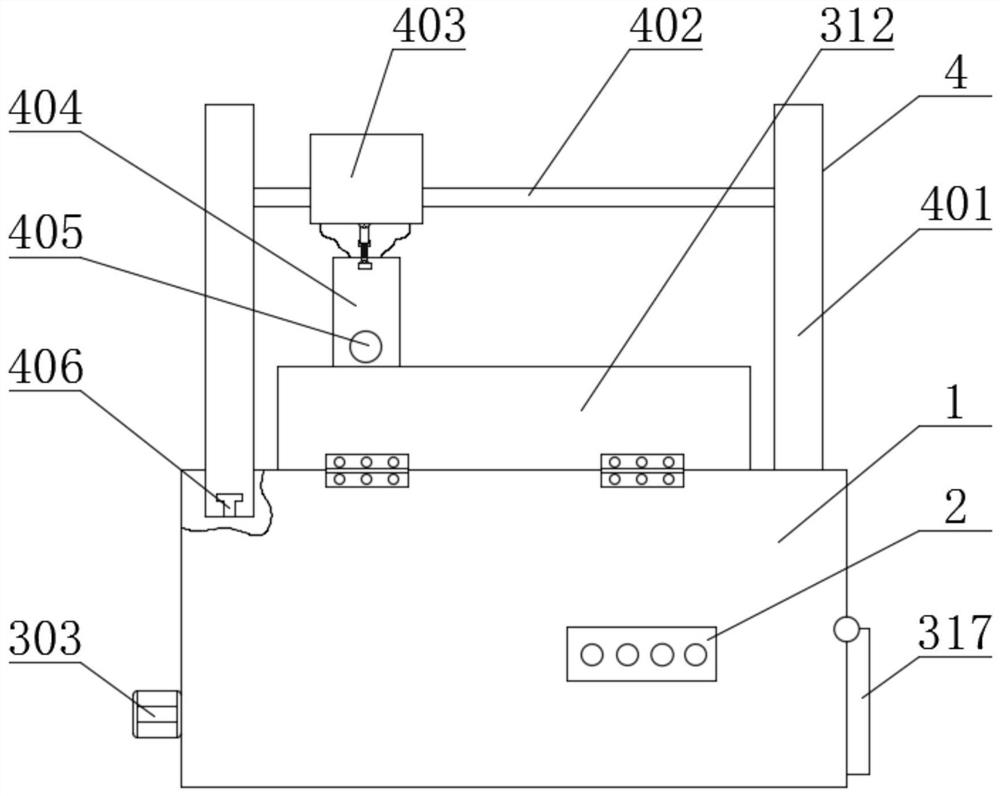

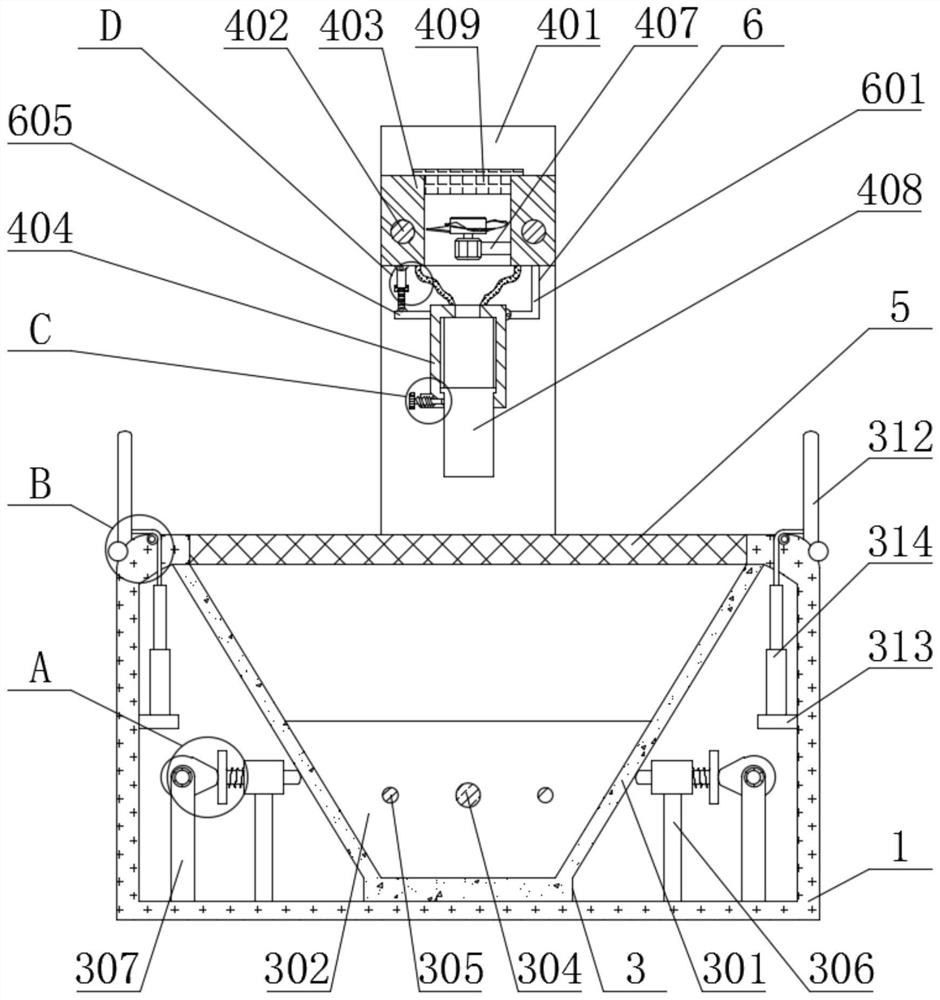

[0032] see Figure 1-7 , the present invention provides a technical solution:

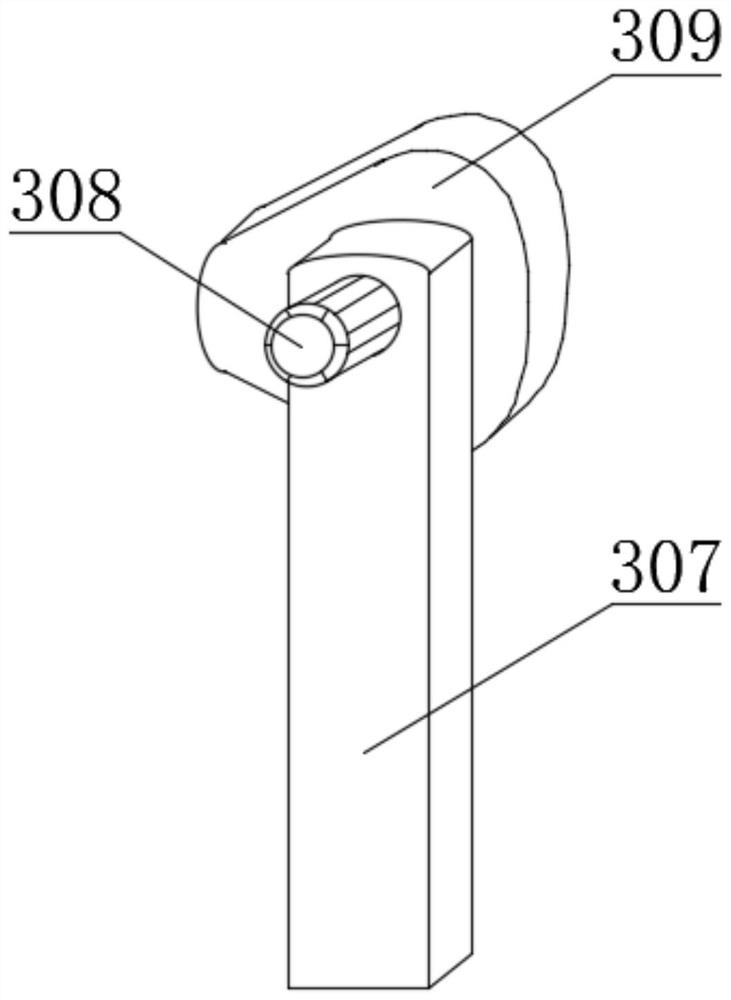

[0033]A welding device with the function of removing dust and slag, comprising a housing 1, a controller 2 at the front end of the housing 1, and a grid plate 5 inside the top end of the housing 1. A slag collecting device 3 is arranged on the inner side of the housing 1, and The slag collecting device 3 comprises a collection tank 301, a support plate 307, a limit ring 306, a connecting plate 313, a first motor 303, a first limit rod 305 and a side plate 312, and the support plate 307 and the limit ring 306 are all fixedly connected to the The inner side of the bottom of the housing 1 and the inner side of the top of the limit ring 306 are slidingly connected to the knock rod 310. The knock rod 310 is arranged on one side of the collection tank 301. The outer side of the knock rod 310 is provided with a spring 311. The two sides of the spring 311 The ends are respectively fixedly connected with t...

Embodiment 2

[0037] Embodiment 2: In this embodiment, the same parts as in Embodiment 1 will not be described in detail. What is not needed is that the present invention can also adjust the air suction port of the inner cylinder 408 through the ventilation steering adjustment mechanism 6, which increases the convenience of use When it is necessary to turn around, turn the turntable 603 by hand, the rotation of the turntable 603 will drive the third screw 604 to move upward or downward, and the up and down movement of the third screw 604 will drive the outer cylinder 404 to center on the bottom end of the connecting rod 601 Rotate to realize the adjustment of the position of the air suction port of the inner cylinder 408, which has good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com