Hole groove machining device facilitating assembly and disassembly for plastic product machining

A technology for processing devices and plastic products, which is applied in the field of plastic products, can solve the problems of low degree of automation of processing equipment, time-consuming and labor-intensive problems, and achieve the effects of improving practicability, convenience, and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

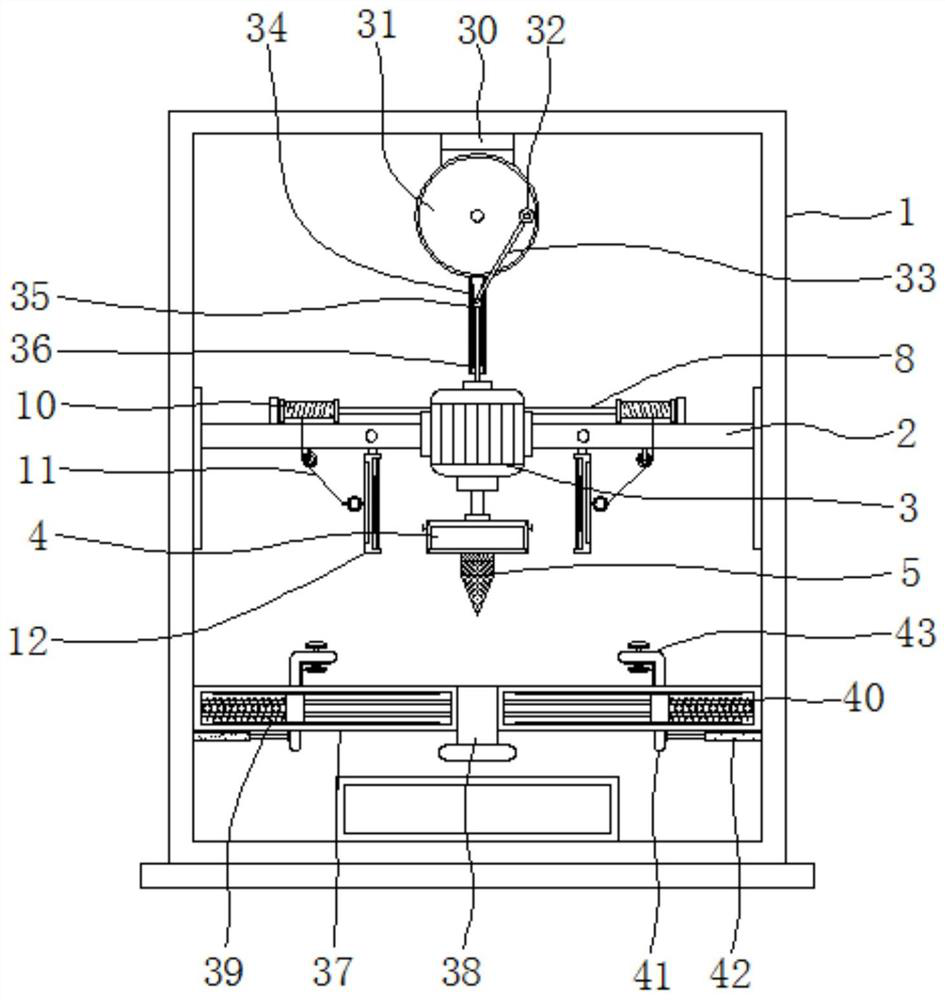

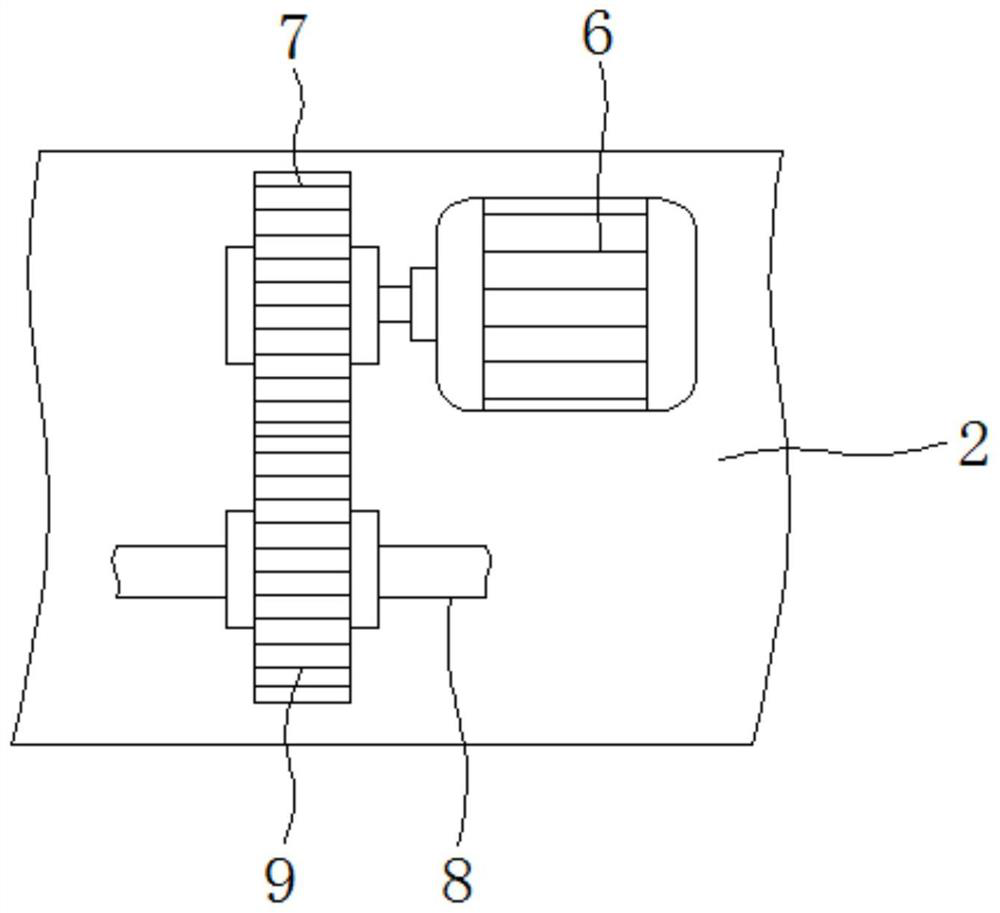

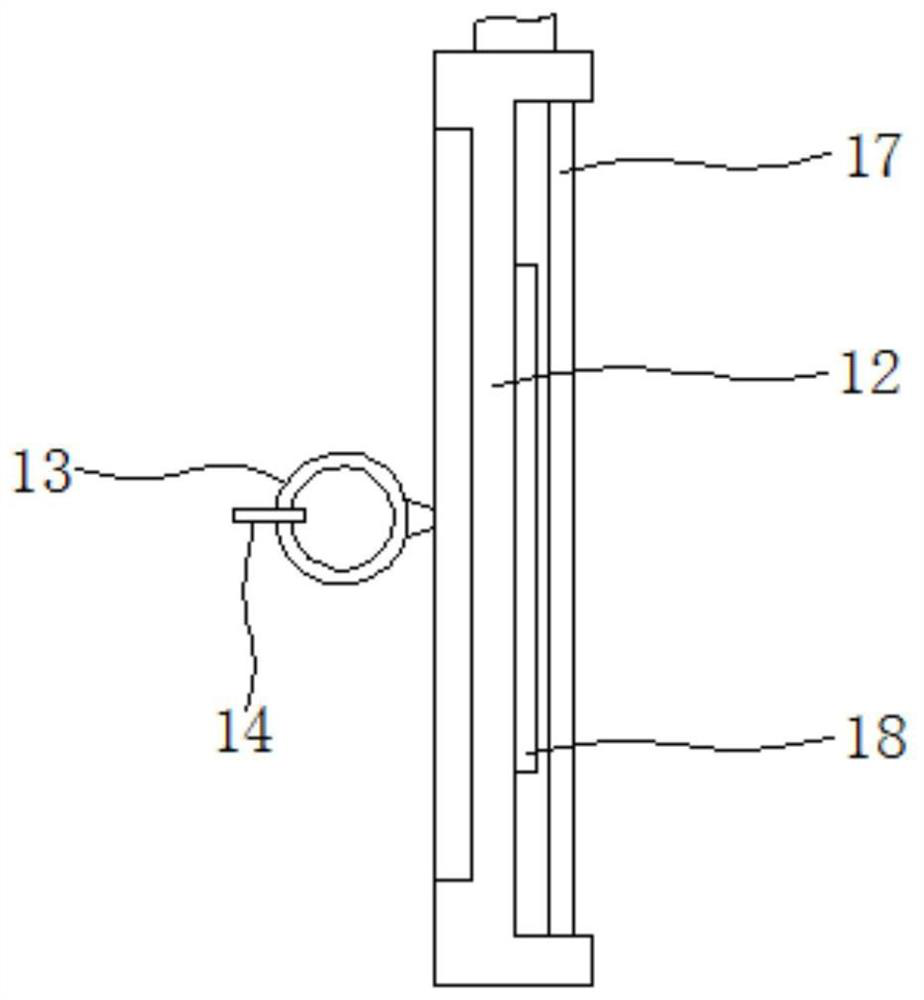

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the hole processing device for processing plastic products that is convenient for loading and unloading provided by the present invention; figure 2 for figure 1 The schematic diagram of the top view structure of the sliding plate shown; image 3 for figure 1 The schematic diagram of the structure of the protective plate shown; Figure 4 for image 3 The schematic diagram of the top view structure of the hook shown; Figure 5 for image 3 The schematic diagram of the back structure of the protective plate shown; Figure 6 for figure 1 The schematic diagram of the cross-sectional structure of the connection box shown; Figure 7 for figure 1 A schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com