Cutting equipment with adjustable angle fixing structure

A technology for fixing structures and cutting equipment, applied in shearing equipment, metal processing equipment, solid separation, etc., can solve problems such as poor recovery effect, poor use effect, inconvenient cutting on inclined surfaces, etc., to prevent offset, automatic Adapt to the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

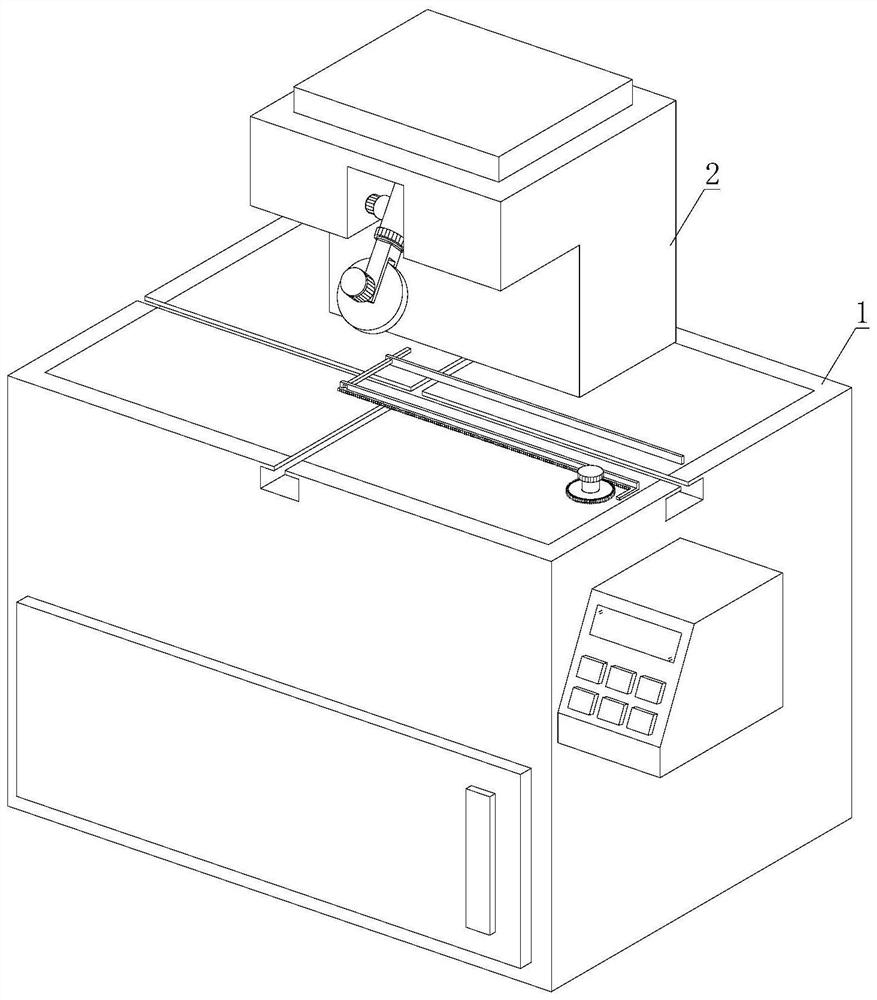

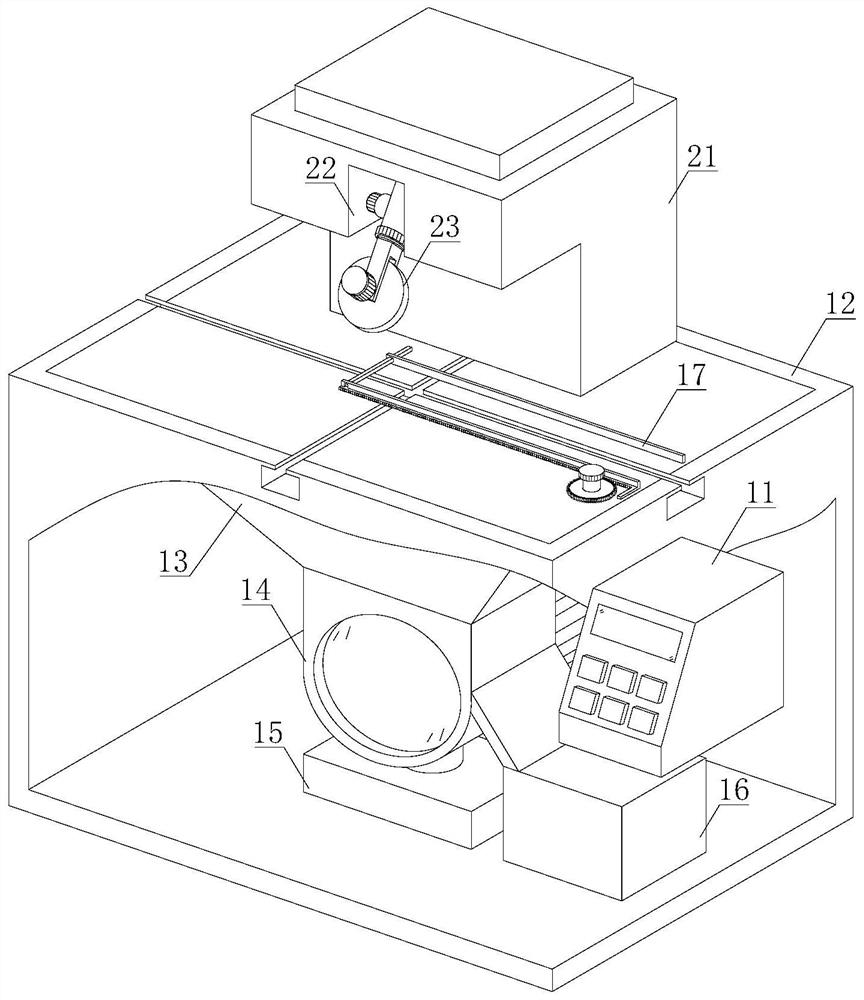

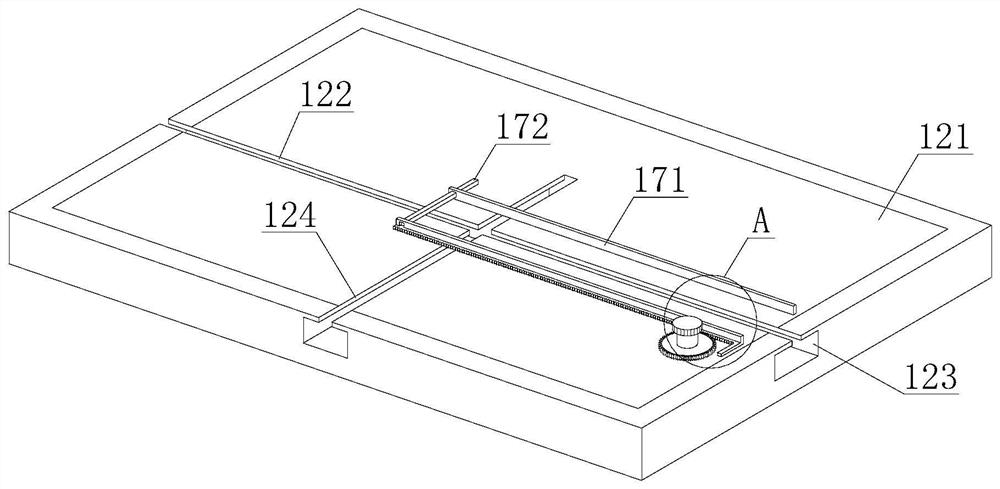

[0030] refer to figure 1 and figure 2, a cutting device with an adjustable angle fixing structure, including a workbench 1 and a cutting assembly 2, the cutting assembly 2 is arranged on the upper end of the workbench 1, and the workbench 1 includes a control panel 11, a cutting table 12, a waste bin 13, a classification Mechanism 14, sawdust warehouse 15, storage mechanism 16 and guide mechanism 17, control panel 11 is fixedly installed on one end of workbench 1, cutting platform 12 is fixedly installed on the upper end of workbench 1, waste material bin 13 is arranged on the lower end of cutting platform 12, The sorting mechanism 14 is arranged on the lower end of the waste bin 13, the sawdust bin 15 is arranged on the lower end of the sorting mechanism 14, the storage mechanism 16 is arranged on one side of the sorting mechanism 14, and the guide mechanism 17 is arranged on the upper end of the workbench 1; the cutting assembly 2 includes a support Frame 21, groove 22 and...

Embodiment 2

[0036] refer to figure 1 and figure 2 , a cutting device with an adjustable angle fixing structure, including a workbench 1 and a cutting assembly 2, the cutting assembly 2 is arranged on the upper end of the workbench 1, and the workbench 1 includes a control panel 11, a cutting table 12, a waste bin 13, a classification Mechanism 14, sawdust warehouse 15, storage mechanism 16 and guide mechanism 17, control panel 11 is fixedly installed on one end of workbench 1, cutting platform 12 is fixedly installed on the upper end of workbench 1, waste material bin 13 is arranged on the lower end of cutting platform 12, The sorting mechanism 14 is arranged on the lower end of the waste bin 13, the sawdust bin 15 is arranged on the lower end of the sorting mechanism 14, the storage mechanism 16 is arranged on one side of the sorting mechanism 14, and the guide mechanism 17 is arranged on the upper end of the workbench 1; the cutting assembly 2 includes a support Frame 21, groove 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com