A sludge desanding method and system for adjusting pH value step by step

A step-by-step adjustment and sludge technology, applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the wear and tear of sludge treatment equipment, the difficulty of effectively increasing the organic matter content, energy consumption and cost problems such as large, to achieve the effect of improving utilization, reducing interference, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

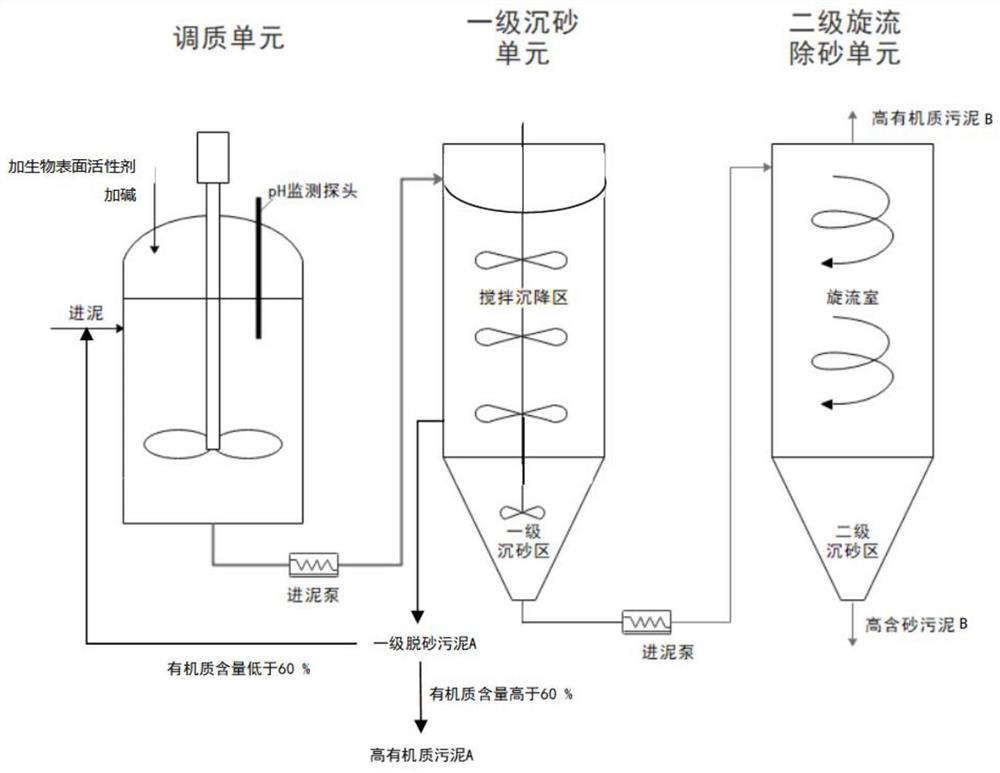

[0049] A sludge desanding method and system for adjusting the pH value step by step, such as figure 1 , including the tempering unit, the first-stage sand settling unit and the second-stage cyclone desanding unit, the steps are as follows:

[0050] (1) Add sandy sludge with volatile solids to total solids ratio (VS / TS) of 55% and a water content of 99% into the conditioning unit, and add NaOH step by step to adjust the pH value. Add the surfactant sophorolipid at 5‰, and stir for 10 minutes at 50 r / min for every 0.3 rise in the pH value until the pH rises to 10.

[0051] (2) The effective volume ratio of the first-stage sand settling unit and the conditioning unit is 1:1, pump 1 / 2 of the sludge volume after adjusting the pH value in the conditioning unit into the first-stage sand settling unit, and the first-stage sand settling unit The volume ratio of the primary sand settling area to the stirring and sedimentation area in the unit is 3:1, the length of the stirring paddle i...

Embodiment 2

[0054] A sludge desanding method and system for adjusting pH value step by step, comprising a conditioning unit, a primary desanding unit and a secondary cyclone desanding unit. Proceed as follows:

[0055] (1) Add sandy sludge with a volatile solid to total solid ratio (VS / TS) of 40% and a water content of 96% into the conditioning unit, and add NaOH step by step to adjust the pH value, so that the dry weight of the sludge is Add surfactant rhamnolipid at 10‰, and stir for 5 minutes at 100 r / min for every 0.5 rise in pH value until the pH rises to 10.

[0056] (2) The effective volume ratio of the first-stage sand settling unit and the conditioning unit is 2:1, pump 1 / 4 of the sludge volume after adjusting the pH value in the conditioning unit into the first-stage sand settling unit, and the first-stage sand settling unit The volume ratio of the primary sand settling area to the stirring and sedimentation area in the unit is 5:1, the length of the stirring paddle in the prim...

Embodiment 3

[0059] A sludge desanding method and system for adjusting pH value step by step, comprising a conditioning unit, a primary desanding unit and a secondary cyclone desanding unit. Proceed as follows:

[0060] (1) Add sandy sludge with a volatile solid to total solid ratio (VS / TS) of 35% and a moisture content of 98% into the conditioning unit, and add NaOH step by step to adjust the pH value, so that the dry weight of the sludge is 8‰ Add surfactant phospholipids, and stir for 5 minutes at 80r / min for every 0.5 rise in pH value until the pH rises to 10.

[0061] (2) The effective volume ratio of the first-stage sand settling unit and the conditioning unit is 2:1, and 1 / 3 of the sludge volume after adjusting the pH value in the conditioning unit is pumped into the first-stage sand settling unit, and the first-stage sand settling unit The volume ratio of the primary sand settling area to the stirring and sedimentation area in the unit is 4:1, the length of the stirring paddle in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com