Preservative film

A technology of plastic wrap and vinylidene chloride, which is applied in the field of plastic wrap, can solve the problems of reduced productivity and perforation, and achieve the effects of less frequency of occurrence, excellent cutting performance, and suppression of cracking failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0217] 91.3 parts by mass of vinylidene chloride-based resin with a weight average molecular weight of 90,000 (vinylidene chloride repeating unit is 88 mol%, vinyl chloride repeating unit is 12 mol%), acetyl tributyl citrate (Taoka Chemical Industry Co., Ltd.) 8.1 parts by mass and 0.6 parts by mass of epoxidized soybean oil (Newcizer 510R, NOF Corporation) were mixed for 5 minutes with a Henschel mixer. After mixing, the mixture is aged for more than 24 hours to obtain a composition.

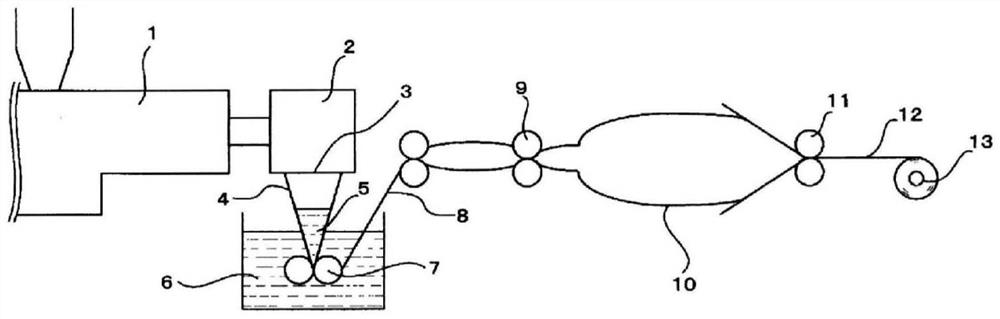

[0218] The obtained composition was supplied to a melt extruder and melted, and melted and extruded from an annular die attached to the front end of the extruder to form a soaking portion. At this time, the heating conditions of the extruder were adjusted so that the temperature of the molten resin at the branch outlet of the ring die was 170° C., and a ring shape was extruded at an extrusion rate of 10 kg / hr.

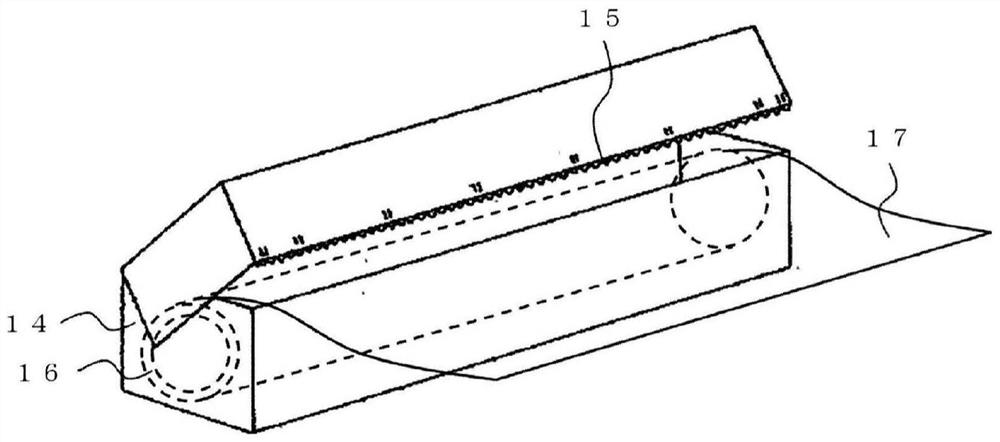

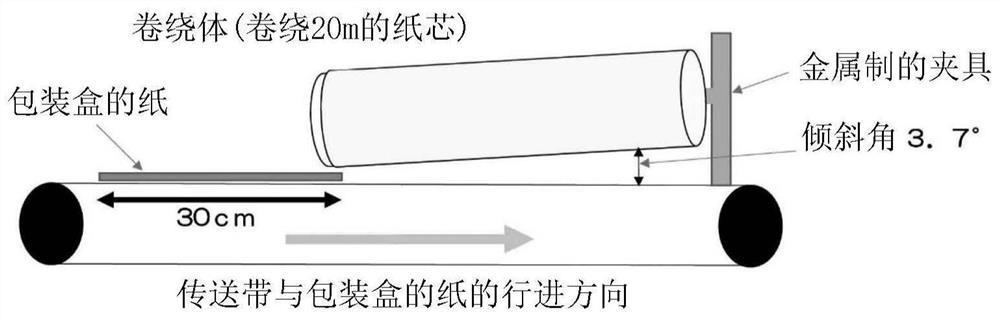

[0219] After it is cooled in the soaking liquid and cold water tank, the parison i...

Embodiment 2~6、 comparative example 1~7

[0222] Except having changed into each condition shown in Table 1, it carried out similarly to Example 1, and obtained the wound body of the wrap film of Examples 2-6 and Comparative Examples 1-7. Each evaluation was performed using the roll body of the obtained wrap film.

[0223]

[0224] ※ATBC: Acetyl tributyl citrate

[0225] DBS: dibutyl sebacate

[0226] DALG: Diacetyllauroylglycerin

[0227] ESO: Epoxidized soybean oil

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com