PBAT/PHA/wood powder composition suitable for preparing thin film and preparation and application of PBAT/PHA/wood powder composition

A technology of composition and wood powder, which is applied in the field of PBAT/PHA/wood powder composition, can solve the problems of reducing costs and reducing the amount of PBAT from petrochemical sources, and achieves the effects of reducing costs, ensuring biodegradability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

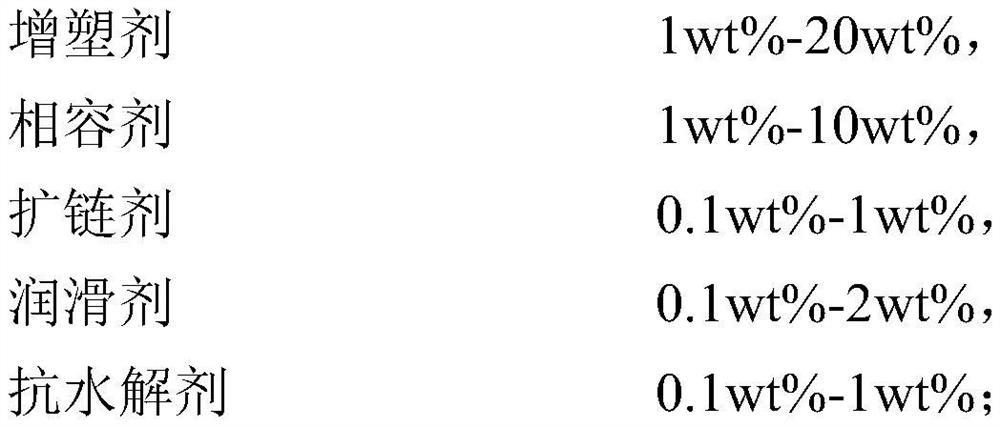

[0067] PBAT / PHA / wood flour composition, comprising the following raw materials:

[0068] 55 parts by weight of PBAT BX8145, 10 parts by weight of PHA F1005, 23 parts by weight of poplar wood powder;

[0069] Based on the total weight of PBAT, PHA and poplar wood powder, triethanolamine 8wt%, EMH3wt%, KC-37280.2wt%, triglyceryl distearate 0.8wt%, N,N'-bis(2,6- Diisopropylphenyl) carbodiimide 0.1 wt%.

Embodiment 2

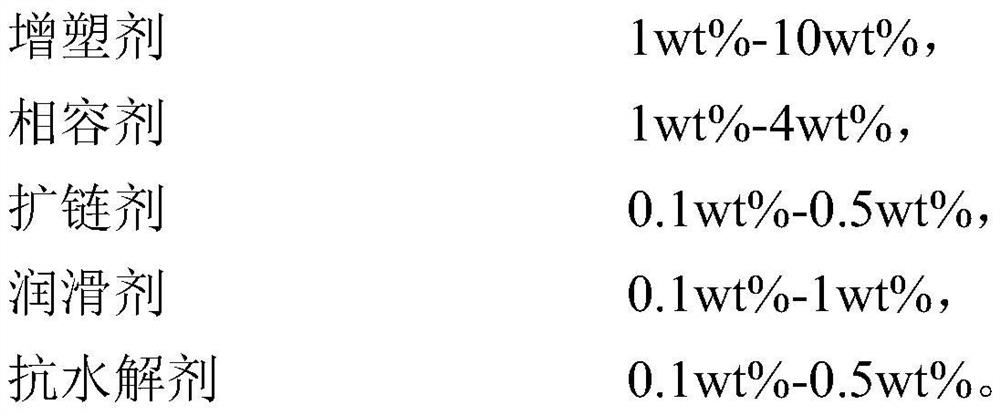

[0071] PBAT / PHA / wood flour composition, comprising the following raw materials:

[0072] 45 parts by weight of PBAT C1200, 20 parts by weight of PHA EM40010, 25 parts by weight of poplar wood powder;

[0073] Based on the total weight of PBAT, PHA and poplar wood flour, diethanolamine 7.5wt%, PBS-g-GMA 2wt%, ADR-4468 0.2wt%, pentaerythritol stearate 0.3wt%, poly-di(1,3 , 5-triisopropylphenyl) carbodiimide 0.2wt%.

Embodiment 3

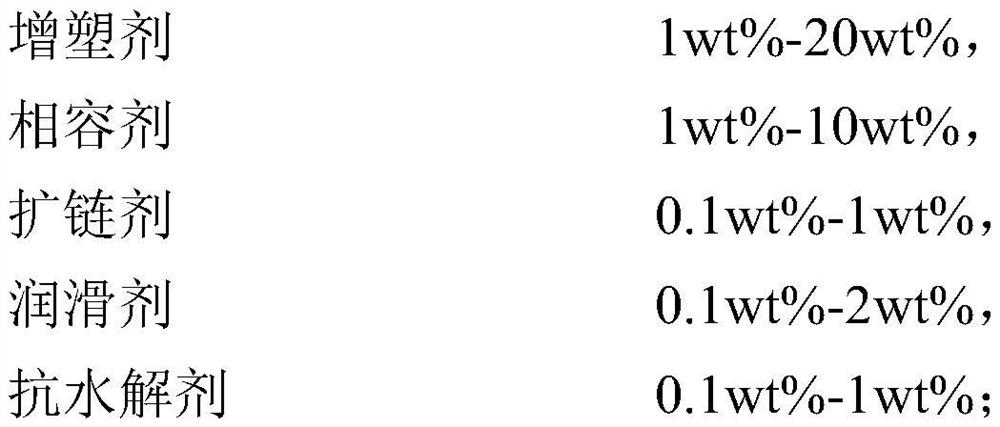

[0075] PBAT / PHA / wood flour composition, comprising the following raw materials:

[0076] 55 parts by weight of PBAT C1200, 12 parts by weight of PHA EM10080, 25 parts by weight of poplar wood powder;

[0077] Based on the total weight of PBAT, PHA and poplar wood powder, triglycerol 3.5wt%, EBA-GMA 4wt%, ADR-4400 0.3wt%, pentaerythritol stearate 0.2wt%, polymerized carbodiimide UN- 03 0.3 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com