Preparation method of special carbon black water-phase dispersion liquid for fruit cultivating bag paper

A technology for growing fruit bag paper and carbon black water, applied in chemical instruments and methods, papermaking, paper coatings, etc., can solve problems such as unevenness, loss and dispersion of carbon black, and achieve improved uniformity, low production cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

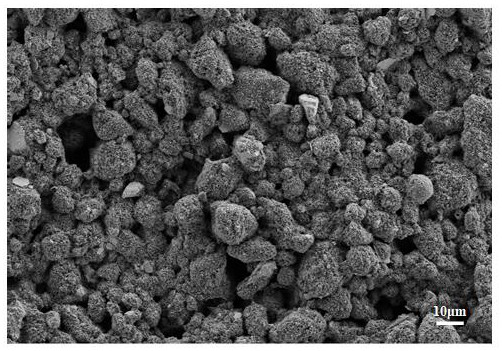

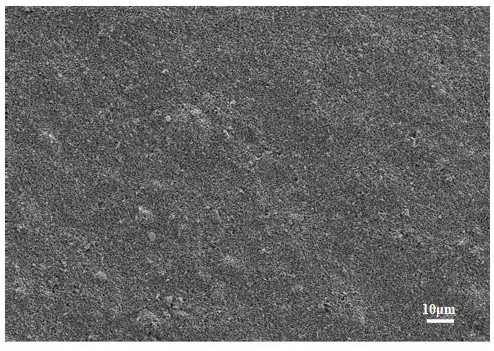

Image

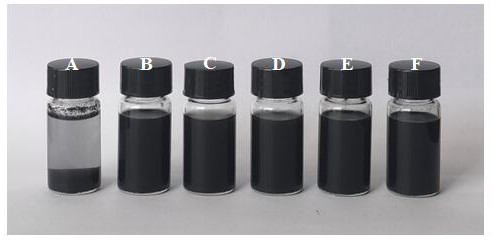

Examples

Embodiment 1

[0028] (1) Prepare sodium lauroyl sarcosinate solution: Dissolve 0.6 wt.% (to absolute dry carbon black) sodium lauroyl sarcosinate in 40 ml deionized water, adjust the pH to 8.0~8.5, 1200 r / min Stir at a shear rate for 15 min to obtain a sodium lauroyl sarcosinate solution;

[0029] (2) Preparation of hydroxypropyl methylcellulose solution: Dissolve 1.4 wt.% (to absolute dry carbon black) of hydroxypropyl methylcellulose in 40 ml of deionized water, adjust the pH to 8.0-8.5, 1200 r Stir 15 min under the shear speed of / min, obtain hydroxypropyl methylcellulose solution;

[0030] (3) Preparation of dispersant: Mix the sodium lauroyl sarcosinate solution obtained in step (1) with the hydroxypropyl methylcellulose solution obtained in step (2), adjust the pH to 8.0~8.5, and Continue stirring for 30 min under the min shear rate to obtain a dispersant;

[0031] (4) Preparation of carbon black aqueous dispersion: Add carbon black to the dispersant prepared in step (3), continue s...

Embodiment 2

[0033] (1) Prepare sodium lauroyl sarcosinate solution: Dissolve 0.8 wt.% (relative to absolute dry carbon black) sodium lauroyl sarcosinate in 40 ml deionized water, adjust the pH to 8.0~8.5, 1200 r / min Stir at a shear rate for 15 min to obtain a sodium lauroyl sarcosinate solution;

[0034] (2) Preparation of hydroxypropyl methylcellulose solution: Dissolve 1.2 wt.% (relative to absolute dry carbon black) of hydroxypropyl methylcellulose in 40 ml of deionized water, adjust the pH to 8.0~8.5, 1200 r Stir 15 min under the shear speed of / min, obtain hydroxypropyl methylcellulose solution;

[0035] (3) Preparation of dispersant: Mix the sodium lauroyl sarcosinate solution obtained in step (1) with the hydroxypropyl methylcellulose solution obtained in step (2), adjust the pH to 8.0~8.5, and Continue stirring for 30 min under the min shear rate to obtain a dispersant;

[0036] (4) Preparation of carbon black aqueous dispersion: Add carbon black to the dispersant prepared in st...

Embodiment 3

[0038] (1) Prepare sodium lauroyl sarcosinate solution: Dissolve 1.0 wt.% (relative to absolute dry carbon black) sodium lauroyl sarcosinate in 40 ml deionized water, adjust the pH to 8.0~8.5, 1200 r / min Stir at a shear rate for 15 min to obtain a sodium lauroyl sarcosinate solution;

[0039] (2) Preparation of hydroxypropyl methylcellulose solution: Dissolve 1.0 wt.% (to absolute dry carbon black) of hydroxypropyl methylcellulose in 40 ml of deionized water, adjust the pH to 8.0-8.5, 1200 r Stir 15 min under the shear speed of / min, obtain hydroxypropyl methylcellulose solution;

[0040] (3) Preparation of dispersant: Mix the sodium lauroyl sarcosinate solution obtained in step (1) with the hydroxypropyl methylcellulose solution obtained in step (2), adjust the pH to 8.0~8.5, and Continue stirring for 30 min under the min shear rate to obtain a dispersant;

[0041] (4) Preparation of carbon black aqueous dispersion: Add carbon black to the dispersant prepared in step (3), c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com