Method for improving benefits of trialiphatic amine leaching uranium extraction process

A tri-fatty amine and benefit technology is applied in the field of improving the benefit of the tri-fatty amine leaching extraction and uranium extraction process, and can solve the problems of low extraction capacity, large amount of ammonium sulfate generated, and the influence of extraction capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

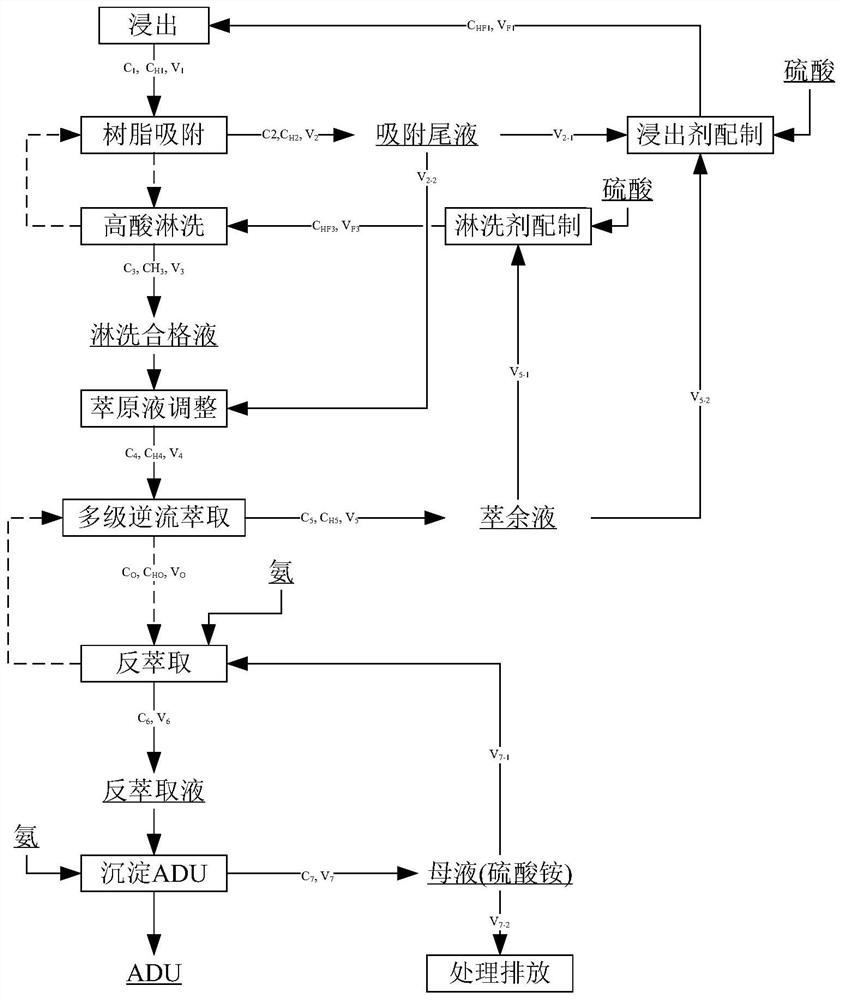

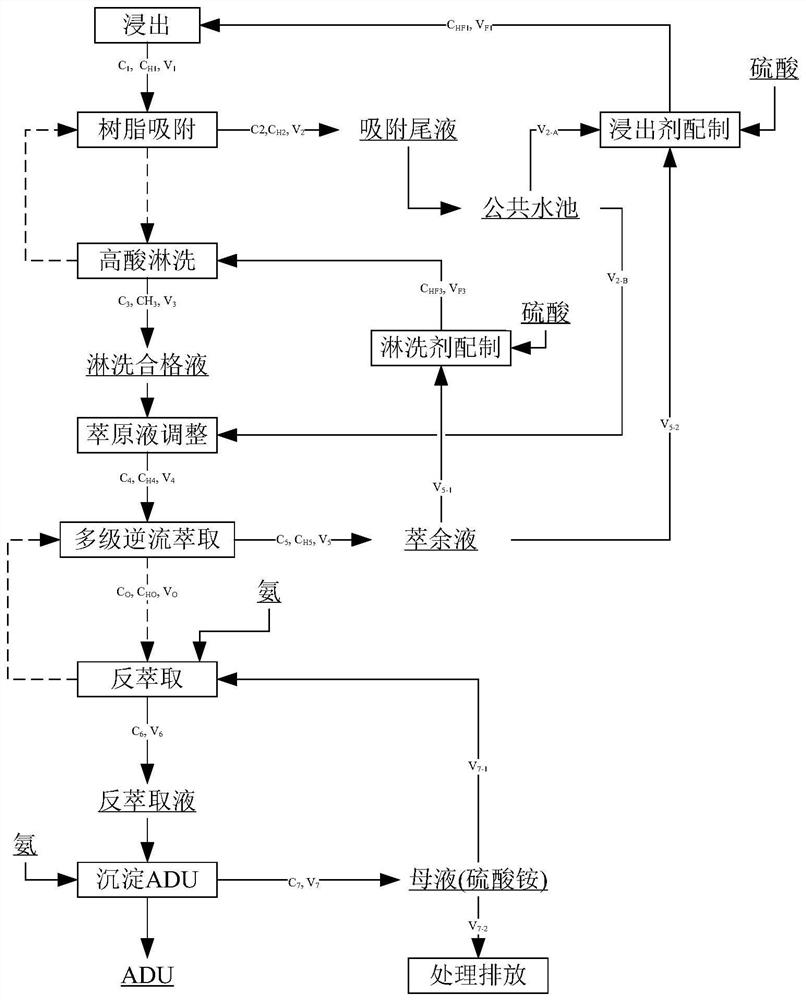

[0041] A method for improving the benefit of tri-aliphatic amine leaching and extracting uranium process, step 1, using sulfuric acid to leach the crushed ore, setting the acid consumption as Q, the unit is kg / t ore, and the unit for in-situ leaching is kg / t kg uranium, the concentration of uranium in the leaching solution is C 1 , the unit is g / L, the concentration of sulfuric acid is C H1 , the unit is g / L, 1t ore, or 1kg uranium in the in-situ leaching leachate, when the leachate volume is V 1 , the unit is L;

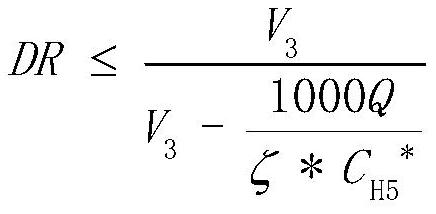

[0042] Step 2, adopting strong basic resin to adsorb the leaching solution to obtain a saturated resin, the volume of the adsorption tail liquid is V 2 , the unit is L, and then use high-concentration sulfuric acid to rinse, and the concentration of sulfuric acid is C HF3 , the unit is g / L, C HF3 ≥80g / L; obtain the eluting qualified liquid, the qualified liquid uranium concentration is C 3 , the unit is g / L, the concentration of sulfuric acid is C H2, the unit...

example 2

[0065] A uranium ore with a uranium grade of 0.117% was leached with conventional sulfuric acid stirring. The acid consumption is 30kg / t ore. The leaching liquid-solid ratio is 2L / kg. Use 201×7 to adsorb uranium in the leaching solution to obtain a saturated resin of 50 mg / ml. Use 100g / L sulfuric acid to rinse the saturated resin. The volume of the eluent is 25BV.

[0066] When DR=1, use N235 organic relative eluting liquid to extract, obtain saturated uranium concentration of 1.95g / L, raffinate 54.3% returns to leaching (volume accounts for 13.8% of leaching agent, extraction returns sulfuric acid to 25kg / t ore ), 45.7% back to the eluent preparation (volume accounts for 45.7% of the eluent, sulfuric acid accounts for 41.6% of the eluent). Use ammonia water and ammonium sulfate to back-extract the saturated organic phase to obtain a stripping liquid with a uranium concentration of 5.85g / L, add ammonia to precipitate ADU, and return the mother liquor to back-extraction prep...

example 3

[0069] A uranium ore with a uranium grade of 0.117% was leached with conventional sulfuric acid stirring. The acid consumption is 30kg / t ore. The leaching liquid-solid ratio is 2L / kg. Use 201×7 to adsorb uranium in the leaching solution to obtain a saturated resin of 50 mg / ml. Use 100g / L sulfuric acid to rinse the saturated resin. The volume of the eluent is 25BV.

[0070] When adopting DR=1, use N235 organic relative eluting qualified solution to extract, get saturated uranium concentration 1.95g / L, raffinate 21.9% return leaching (volume accounts for 5.5% of leaching agent, extraction returns sulfuric acid to be 10kg / t ore ), 78.1% return to the eluent preparation (the volume accounts for 78.1% of the eluent, sulfuric acid accounts for 70.9% of the leaching agent). Use ammonia water and ammonium sulfate to back-extract the saturated organic phase to obtain a stripping liquid with a uranium concentration of 5.85g / L, add ammonia to precipitate ADU, and return the mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com