Test equipment and test method for automatic guidance system assembly of electronic cabin

A technology of automatic guidance and system components, applied in the field of testing, can solve the problems of low efficiency, low reliability and high error rate, and achieve the effect of simplifying the testing process, improving the testing efficiency and improving the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

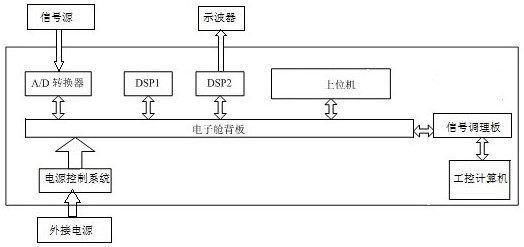

[0034] In order to overcome the problems of separate testing of each component, long test cycle and low work efficiency in the existing electronic cabin automatic guidance system component testing process, the present invention provides such figure 1 Shown is a testing device for electronic cabin automatic guidance system components. The invention connects multiple components centrally through the electronic cabin backplane, improves reliability, safety and precision, and realizes multi-component signal interaction and other functional joint debugging. And compatibility testing between components, simplifying the testing process of components and improving the testing efficiency.

[0035] Such as figure 1 As shown, a test device for electronic cabin automatic guidance system components, including a cabinet, industrial computer, signal conditioning board, power control system, electronic cabin backplane and upper computer, said industrial computer, signal conditioning board, T...

Embodiment 2

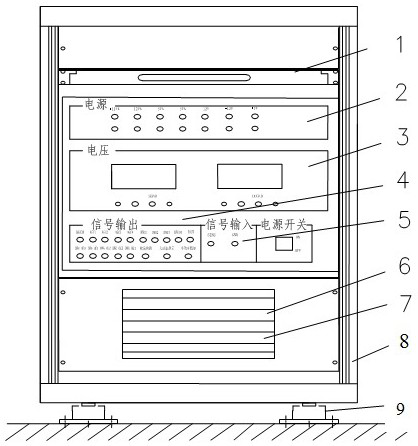

[0038] Such as figure 2 As shown, preferably, on the basis of Embodiment 1, in this embodiment, the host computer is a VG5 single-board computer. The cabinet includes a cabinet housing 8 and legs 9, and the cabinet housing 8 is provided with a display 1, a power panel 2, a voltage panel 3, a signal output panel 4, a signal input panel 5, and an A / D converter With DSP1 and DSP2 installation position 6, upper computer installation position 7, described display 1, signal output panel 4, signal input panel 5 are connected with described industrial control computer, described power supply panel 2, voltage panel 3 and described Power control system connection.

[0039] In actual use, the overall structure of the test equipment adopts an integrated cabinet design, which is compact, safe and reliable; the cabinet is designed with a power panel 2, a voltage panel 3, a signal output panel 4, and a signal input panel, which can provide input signals required for testing. Visually disp...

Embodiment 3

[0049] A method for using testing equipment for electronic cabin automatic guidance system components, using any of the above-mentioned testing equipment for electronic cabin automatic guidance system components, the specific steps include:

[0050] S1: Test preparation, install test components;

[0051] Install the A / D converter, DSP1 and DSP2 in the installation position 6 of the A / D converter, DSP1 and DSP2, install the VG5 single-board computer in the installation position 7 of the VG5 single-board computer, and start the power supply of the test equipment;

[0052] S2: Turn on the power switch of power panel 2 to start component testing;

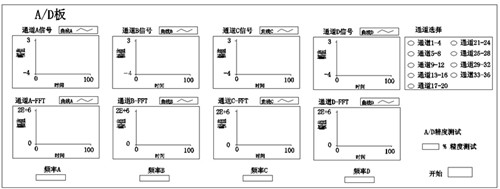

[0053] Such as Figure 6 As shown, after the industrial computer is running, first define the communication data structure, and then send the test command data through the network port according to the defined data format. The VG5 single-board computer receives the test command from the industrial computer through Ethernet and parses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com