Vehicle body draining posture debugging method, computer equipment and storage medium

A debugging method and draining technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as shrinkage cavity, difficult operation, increased dust particles, etc., to reduce operation difficulty and cost, and scope of application The effect of widening and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a method for debugging the draining posture of the vehicle body, which can directly determine the optimal draining posture of the vehicle body corresponding to the current vehicle type before the vehicle body is drained by the painting production line, and the vehicle body can be realized without multiple adjustments of the draining posture The optimal drainage of the corresponding body effectively reduces the difficulty and cost of operation. Moreover, the method for debugging the draining posture of the vehicle body is suitable for draining the vehicle bodies of different models, has a wide range of applications, and reduces the cost.

[0029] Such as figure 1 As shown, the above-mentioned vehicle body drainage posture debugging method includes the following steps:

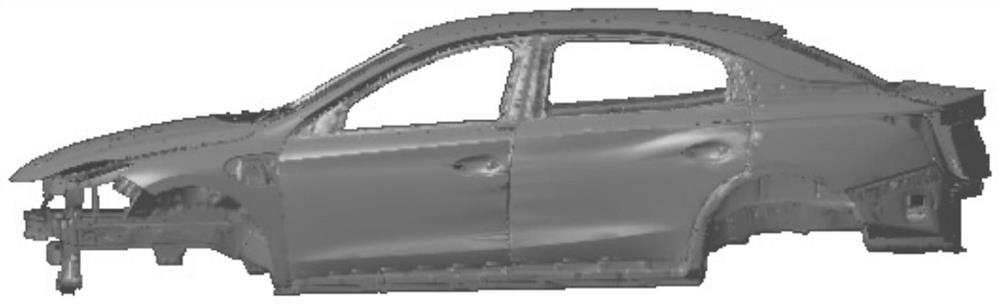

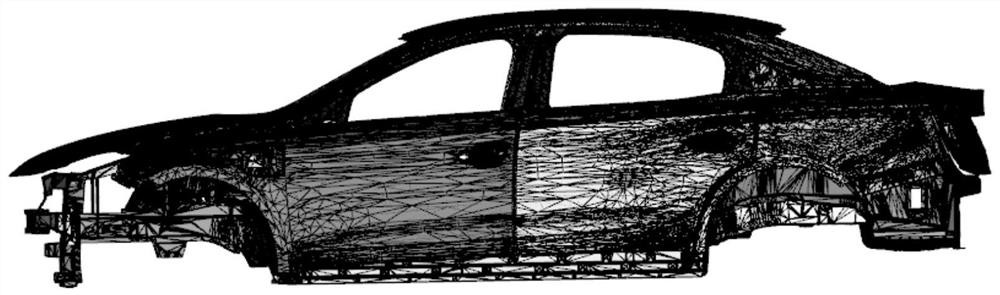

[0030] S1. Establish the digital model of the car body that needs to be drained through 3D software.

[0031] That is, before determining the optimal drainage information, it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com