Low-frequency sound absorption covering layer with gradient change cylindrical cavity

A technology of sound-absorbing covering layer and gradient change, which is applied in the direction of sound-emitting devices and instruments, can solve the problem of narrow frequency bandwidth and achieve simple structure, good underwater low-frequency sound absorption effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

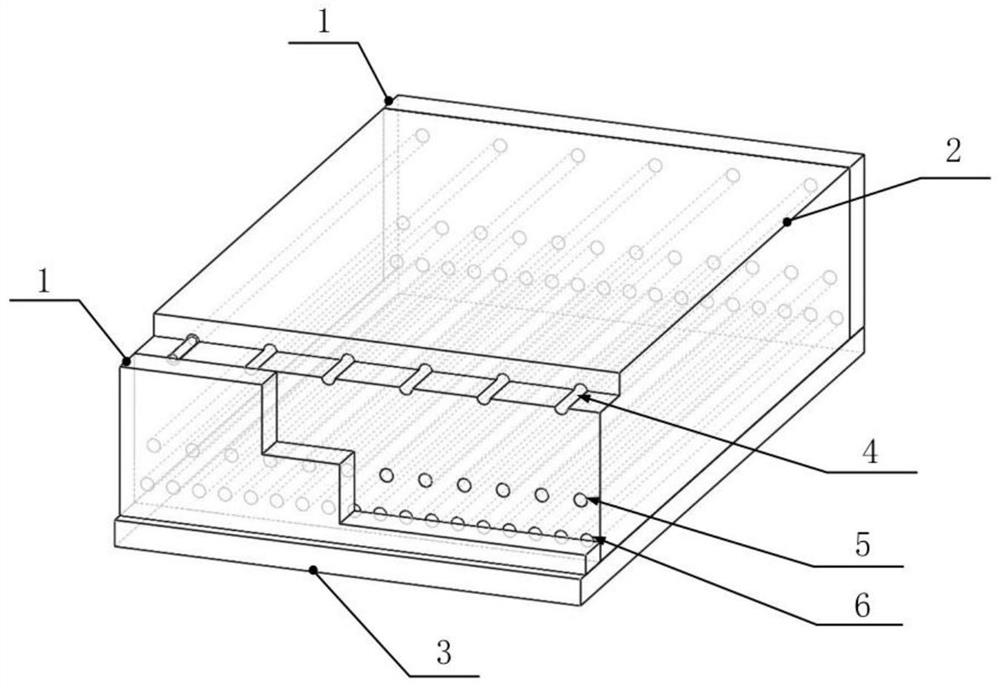

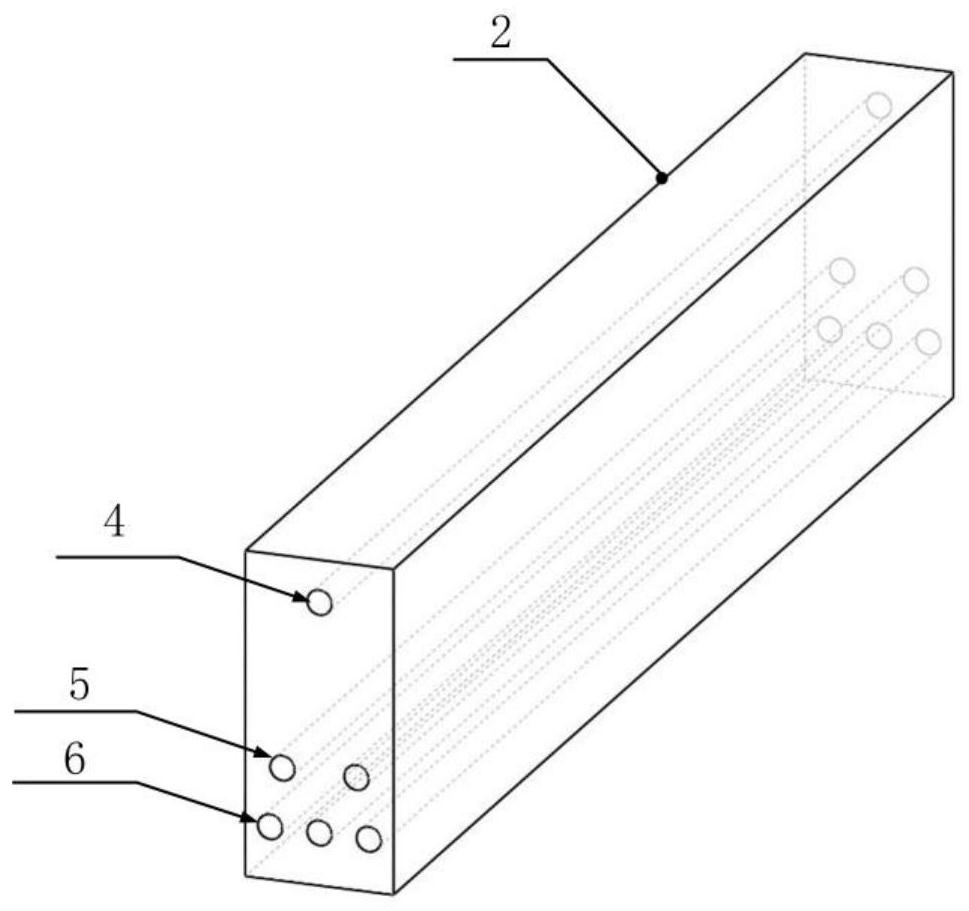

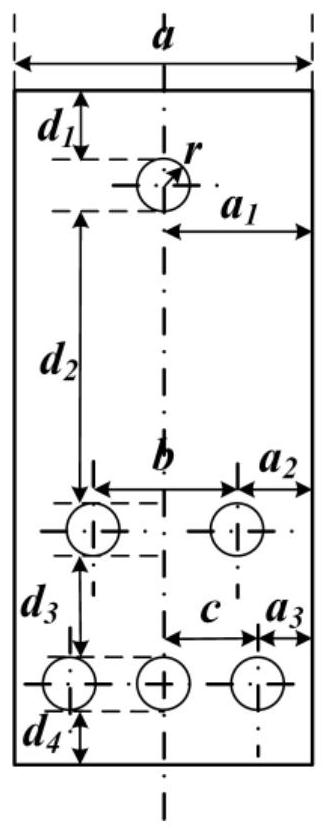

Embodiment 1

[0026] The material of the sound-absorbing layer and the sealing layer in the sound-absorbing covering layer of this example is a kind of PDMS silicone rubber, and the density of PDMS silicone rubber is 1000kg / m 3 , the complex Young's modulus is (1.879+0.540i) MPa, and Poisson's ratio is 0.4997. The density of the base layer is 7890kg / m 3 , Young's modulus is 210GPa, Poisson's ratio is 0.3. Three layers of cylindrical cavities are distributed in the sound-absorbing covering. The sound-absorbing covering layer with the same number and spacing of the cylindrical cavities of the present invention is compared with the sound-absorbing covering layer with the same number and spacing of the cylindrical cavities. For the embodiment of the present invention, the sound-absorbing covering layer with gradient changes in the number and spacing of cylindrical cavities: in each unit, the first layer contains 1 cylindrical cavity, and the second layer contains 2 cylindrical cavities at equ...

Embodiment 2

[0028] The material of the sound-absorbing layer and the sealing layer in the sound-absorbing covering layer of this example is a kind of PDMS silicone rubber, and the density of PDMS silicone rubber is 1000kg / m 3 , the complex Young's modulus is (1.879+0.540i) MPa, and Poisson's ratio is 0.4997. The density of the base layer is 7890kg / m 3 , Young's modulus is 210GPa, Poisson's ratio is 0.3. Three layers of cylindrical cavities are distributed in the sound-absorbing covering.

[0029] The sound-absorbing covering layer with the number and gradient of the cylindrical cavities with different parameters from that of Example 1 was used for comparison with the sound-absorbing covering layer with the same number and spacing of cylindrical cavities. In the embodiment of the present invention, the sound-absorbing covering layer with a gradient change in the number and spacing of cylindrical cavities: in each unit, the first layer contains 1 cylindrical cavity, and the second layer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com