High-energy density pole piece and production method thereof

A high energy density, pole piece technology, applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve problems such as small contact area between current collector surface and active material, limited binder strength, affecting battery performance, etc. , to achieve controllable thickness and uniformity, improve electrical performance and safety performance, and achieve the effect of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

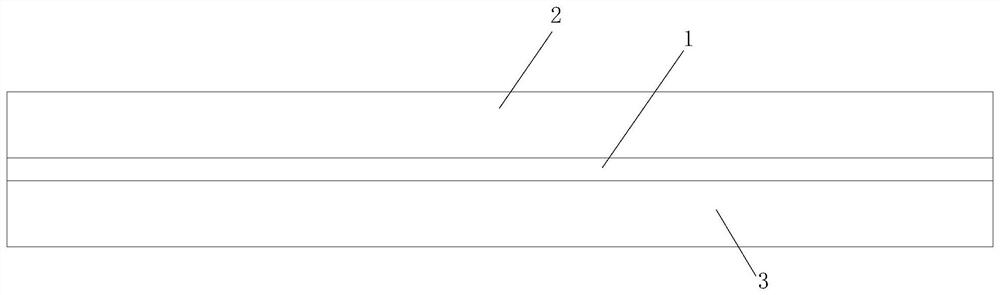

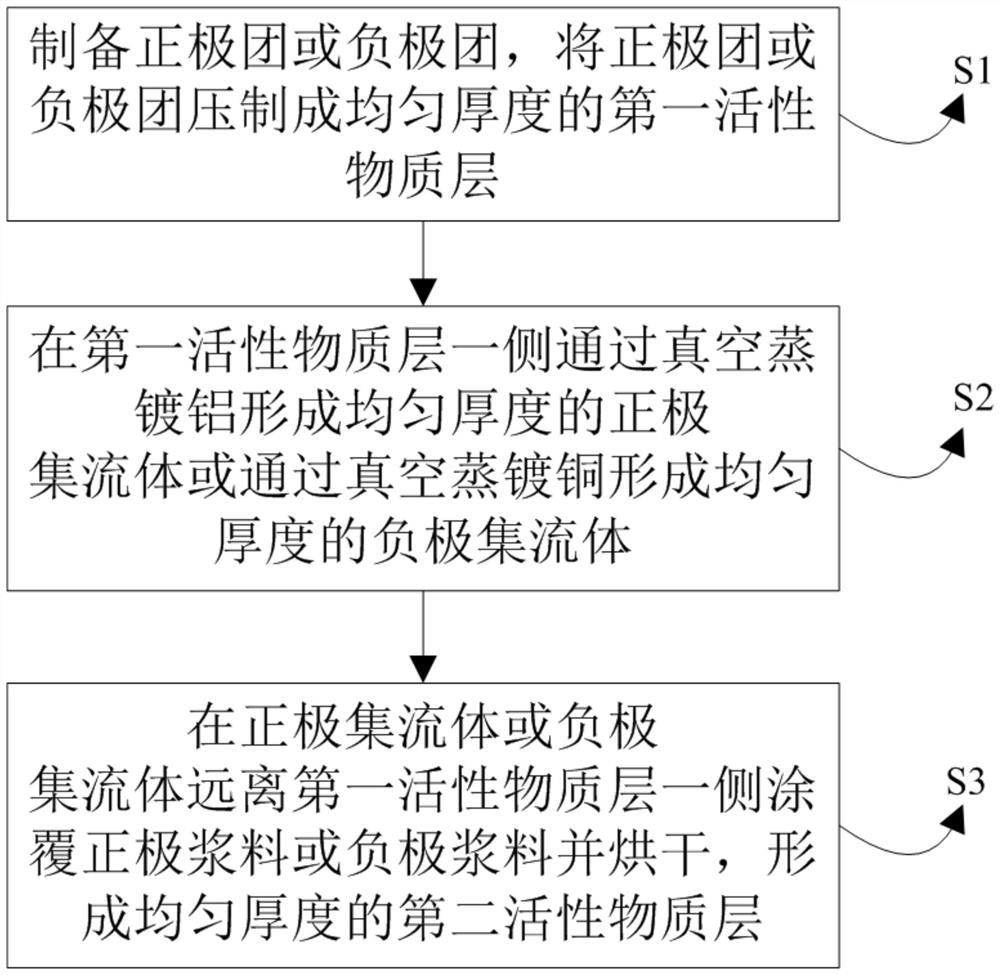

[0021] refer to figure 1 , the present invention proposes a high-energy-density pole piece, including a current collector 1 and a first active material layer 2 and a second active material layer 3 arranged on both sides of the current collector 1, the first active material layer 2 is composed of polar groups Formed by pressing, the current collector 1 is formed by vacuum evaporating metal on the side of the first active material layer 2, and the second active material layer 3 is coated with slurry on the side of the current collector 1 away from the first active material layer 2 material and dried. The areal density of the first active material layer 2 is equal to the areal density of the second active material layer 3 .

[0022] In a specific embodiment, the first active material layer 2 of the high-energy-density positive electrode sheet is formed by pressing the positive electrode group with a roller press. The current collector 1 of the high-energy-density positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com