Large mine stone surface treatment device

A technology of a surface treatment device and a surface treatment chamber, which is applied in the field of mining machinery tooling, can solve problems such as inconvenience and rock research photography errors, and achieve the effect of facilitating research and analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

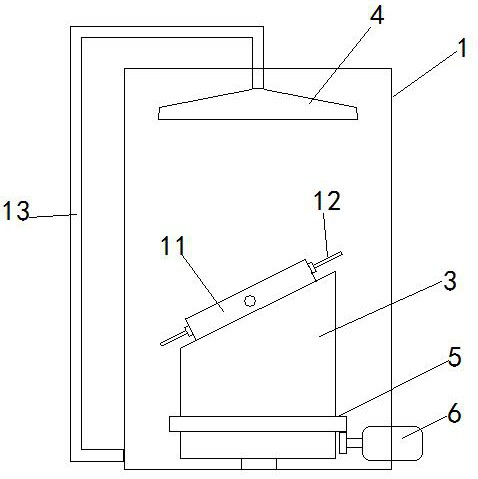

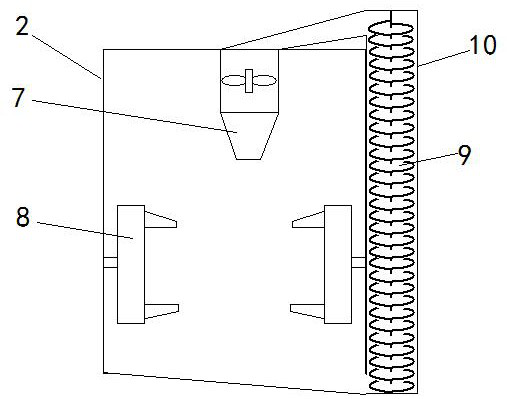

[0014] A large mine stone surface treatment device of the present invention comprises a surface softening chamber 1 and a surface treatment chamber 2, and the large mine stones are sequentially processed through the surface softening chamber 1 and the surface treatment chamber 2;

[0015] The surface softening chamber 1 is provided with a stone fixing platform 3 and an atomizing nozzle 4. The atomizing nozzle 4 is a certain concentration of dilute hydrochloric acid, which can serve the rock surface layer slightly. The stone fixing platform 3 is a cylindrical structure. Fixedly placed on the upper end of the stone fixing platform 3, the center of the bottom surface of the stone fixing platform 3 has a rotating shaft connected to the inner bottom of the surface softening chamber 1, and the stone fixing platform 3 is provided with rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com