Multi-temperature maintenance manufacturing method of combined structure, and combined structure

A combination of structure and strength technology, applied in the field of construction and bridges, can solve problems such as poor technical effect, material bursting, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0761] Embodiment 1.——I type section ( Figure 5 and Figure 6 )

[0762] Steel pipe cement mortar composite structure, at a certain stage in the production process such as Figure 5 and Figure 6 shown. Part A is composed of a steel pipe 11 , a lower blocking plate 12 and an upper blocking plate 13 . A threaded circular hole 121 is provided at the center of the lower blocking plate 12 , and a threaded circular hole is also provided at the center of the upper blocking plate 13 , and a construction pipe 51 is connected to the hole. After the construction is completed, the construction pipe 51 will be unloaded or sawn off.

[0763] The steel pipe 11 of part A adopts Q420 steel, and when the wall thickness is less than or equal to 16mm, its design value of tensile strength is 380MPa. When the temperature does not exceed 300°C, the strength of the steel does not decrease; when the temperature is 374°C, the design strength is 363MPa. The steel pipe 11 is a seamless steel pip...

Embodiment 2

[0801] Embodiment 2.——II type section ( Figure 7 , Figure 8 )

[0802] Nearly completed CFST composite structures such as Figure 7 and Figure 8 shown. Part A of this structure is made up of steel pipe 11 , lower sealing plate 12 and upper sealing plate 13 . There is a feed circular hole 131 at the eccentric position of the upper blocking plate 13, which is used to inject B1 material; at the center of the upper blocking plate, a piston hole is arranged, and a pressurizing piston 6 is inserted in the hole, and the surface of the pressurizing piston Smooth, with a sealing ring set between the piston and the hole wall. There is an isolation device 3 inside the steel pipe. This device is an iron pipe with round holes distributed on the surface. The diameter of the round holes is 5-7mm. The outside of the iron pipe is wrapped with a metal mesh. The mesh is square and the eye width can be between 0.5-2mm. choose between. The iron pipe used as the isolation device is fixed ...

Embodiment 3

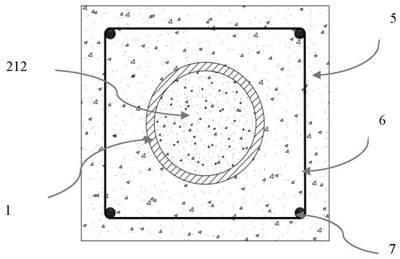

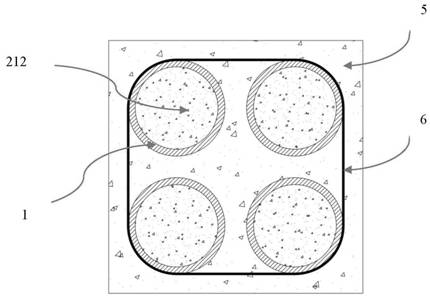

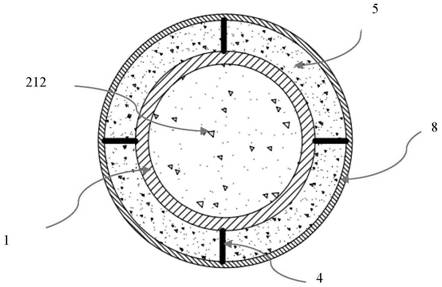

[0807] Embodiment 3.——II type section ( Figure 9 , Figure 10 )

[0808] Concrete-filled steel tube composite structures such as Figure 9 and Figure 10 As shown, part A is composed of a steel pipe 11 , a lower sealing plate 12 and an upper sealing plate 13 . The cavity of part A is provided with an isolating device, which is made up of corrugated iron plates 31 and 32, and the corrugated plates are fixed on the inner wall of the steel pipe. The surrounding area 22 of the corrugated plate is filled with material B2, the areas 211 and 212 between the steel pipe and the corrugated plate are filled with B1 material, and all the areas in the inner wall of part A that are in contact with the B1 material are coated with retarding antifriction material.

[0809] The maximum value that part A can withstand the fluid pressure in the cavity is 55MPa, and after B1 and B2 materials are filled into the cavity, a pressure of 50MPa is applied to it.

[0810] B1 material is reactive po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com