Modified asphalt binder, mixture and preparation method thereof

A technology of asphalt mixture and modified asphalt, which is applied in the direction of building insulation materials, buildings, building components, etc., can solve the problems of easy aging and high temperature degradation, and achieve the effects of avoiding pollution, improving weather resistance, and avoiding the use of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Break 70 kg of butonite bitumen (ash content about 49%) to about 300 mesh, add 30 kg of SK-70 bitumen heated to 160°C at room temperature and stir, then raise the temperature to 175°C, and Grinding at this temperature and by means of a ball mill.

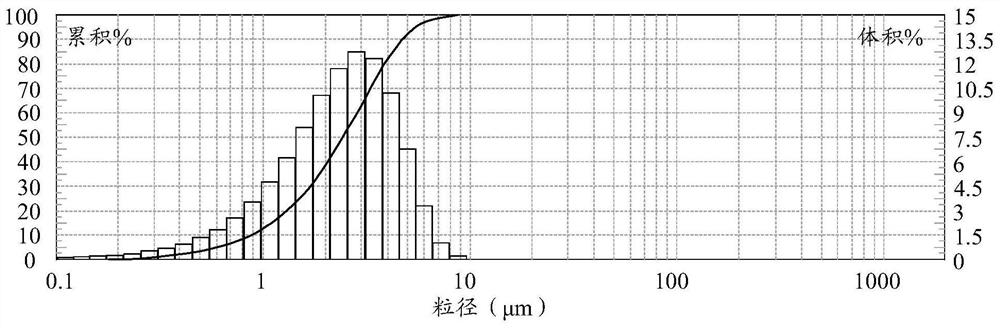

[0050] The trichlorethylene insolubles in the asphalt binder obtained account for 4.5% by volume of particles above 6 microns, and the average particle diameter is 2.6 μm (see figure 1 shown in the particle size distribution diagram), the penetration range is 10-25dmm.

Embodiment 2

[0052] Crumble 30 kg of Iranian rock bitumen (about 9% ash content) to about 300 mesh, add 70 kg of SK-70 pitch that has been heated to 160°C at room temperature and stir, then heat up to 175°C, and temperature and grind by ball mill.

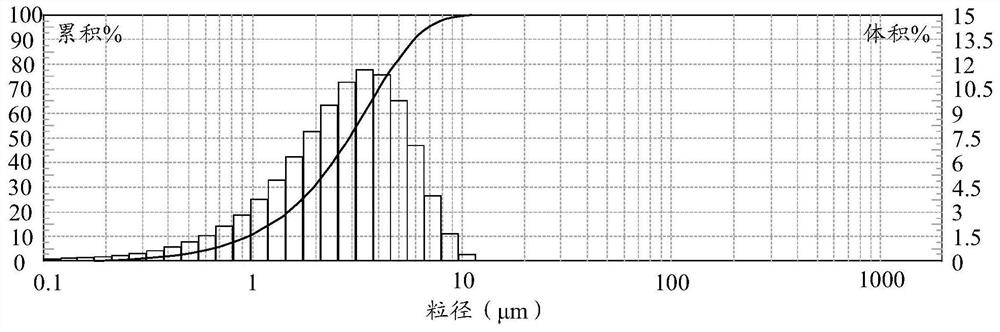

[0053] The trichlorethylene insolubles in the asphalt binder obtained account for 10% by volume of particles above 6 microns, and the average particle diameter is 3.2 μm (see figure 2 shown in the particle size distribution diagram), the penetration range is 10-25dmm.

Embodiment 3

[0055] Crush 60 kg of Trinidad Lake asphalt (about 35% ash content) to about 300 mesh, add 40 kg of SK-70 asphalt heated to 160°C at room temperature and stir, then heat up to 175°C, And grind at this temperature and through a grinder.

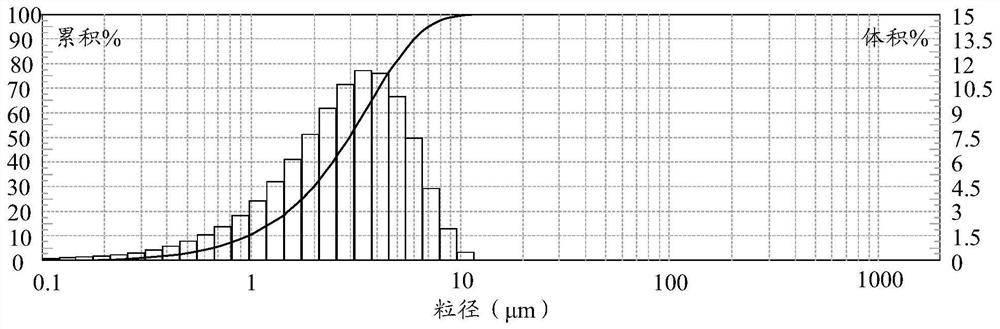

[0056] The trichlorethylene insolubles in the asphalt binder obtained account for 10% by volume of particles above 6 microns, and the average particle diameter is 3.3 μm (see image 3 shown in the particle size distribution diagram), the penetration range is 10-25dmm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com