Automatic detection and report generation equipment for textile fabric process sheet

An automatic detection and report generation technology, applied in the direction of textile testing, material inspection, analysis of materials, etc., can solve problems such as differences, failure to meet the development trend of textiles, unreliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

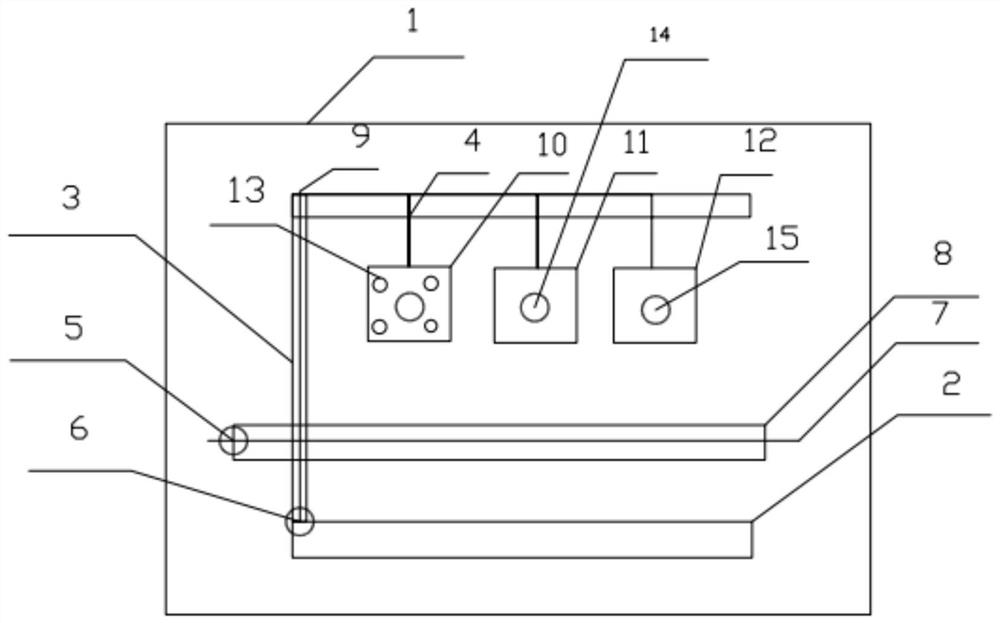

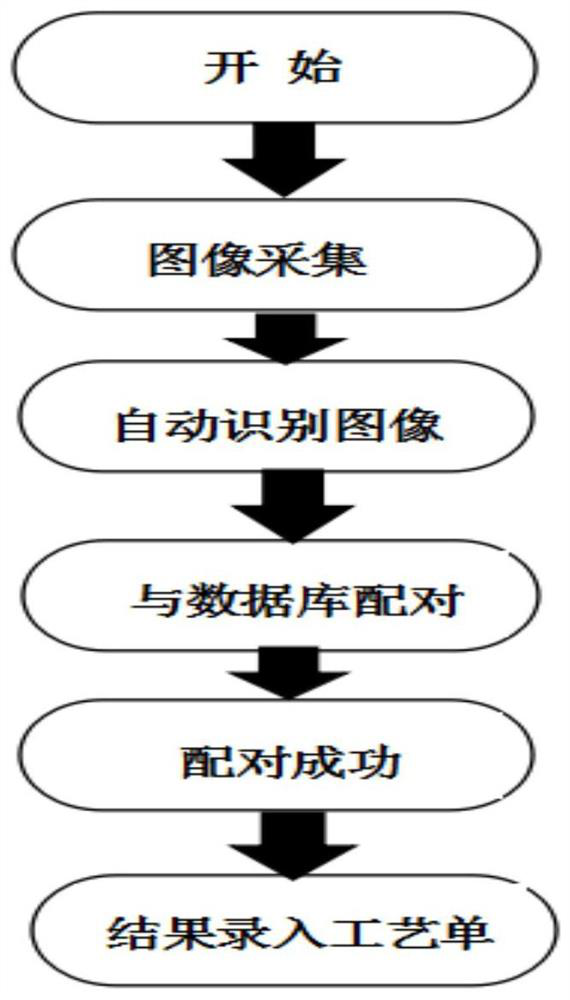

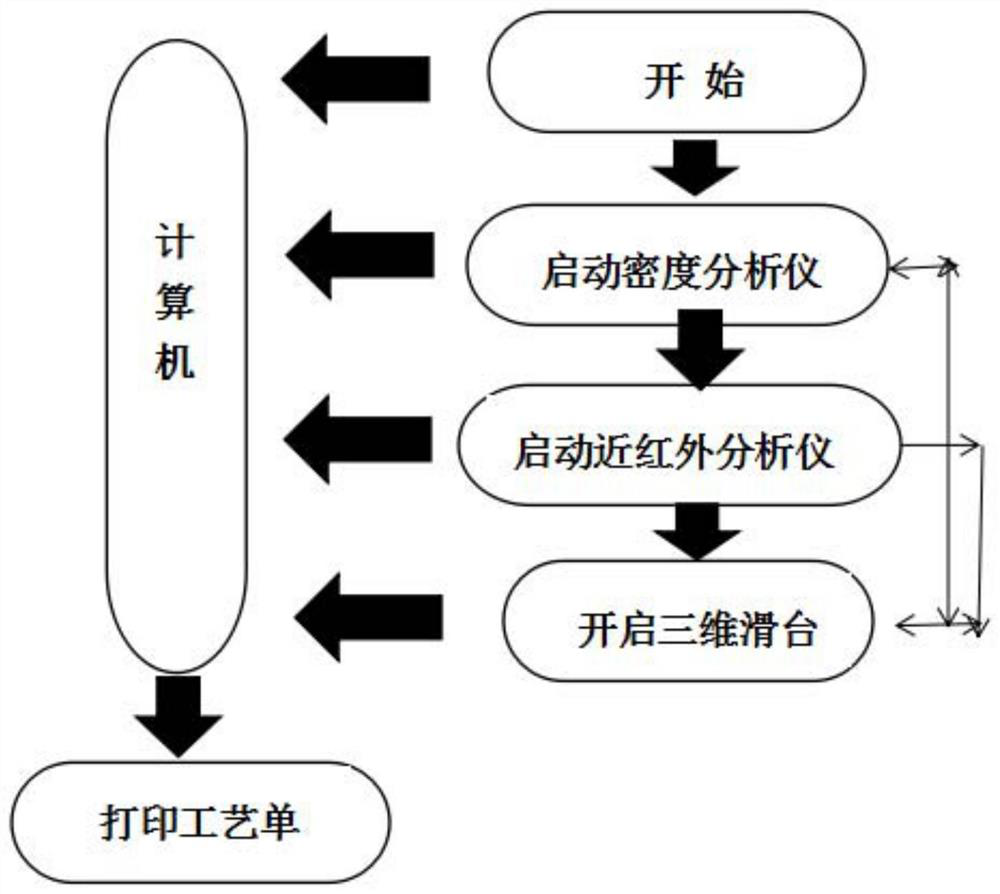

[0016] The present invention will be further described below in combination with specific implementation methods and accompanying drawings. The following functions can be realized through the device: detection of all items of the craft list. See attached Figure 1-4 As shown, an automatic detection and report generation equipment for textile fabric process sheet, which includes the following casing-1, base-2, bracket-3, fixing frame-4, horizontal stepping motor-5, vertical stepping motor-6 , horizontal sliding table track-7, vertical sliding table track-9, horizontal sliding table-8, digital fabric density meter-10 (camera, digital microscope, LED light source-13), computer-12, program software-15, near infrared Spectrometer-11.

[0017] Specifically, the digital fabric density meter includes: digital microscope, LED light source. Digital microscope pixel 200W, 4 LED light sources, support system WIN7 / 8 / 10 / 32 / 64, interface USB2.0. Install the software on your computer and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com