Vibration reduction design method for inner and outer casings of aero-engine under condition of extremely low frequency

An aero-engine, extremely low-frequency technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as engines that are not fundamentally raised, and achieve the effect of reducing low-frequency vibration fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific content of the present invention will be further described below with reference to the accompanying drawings.

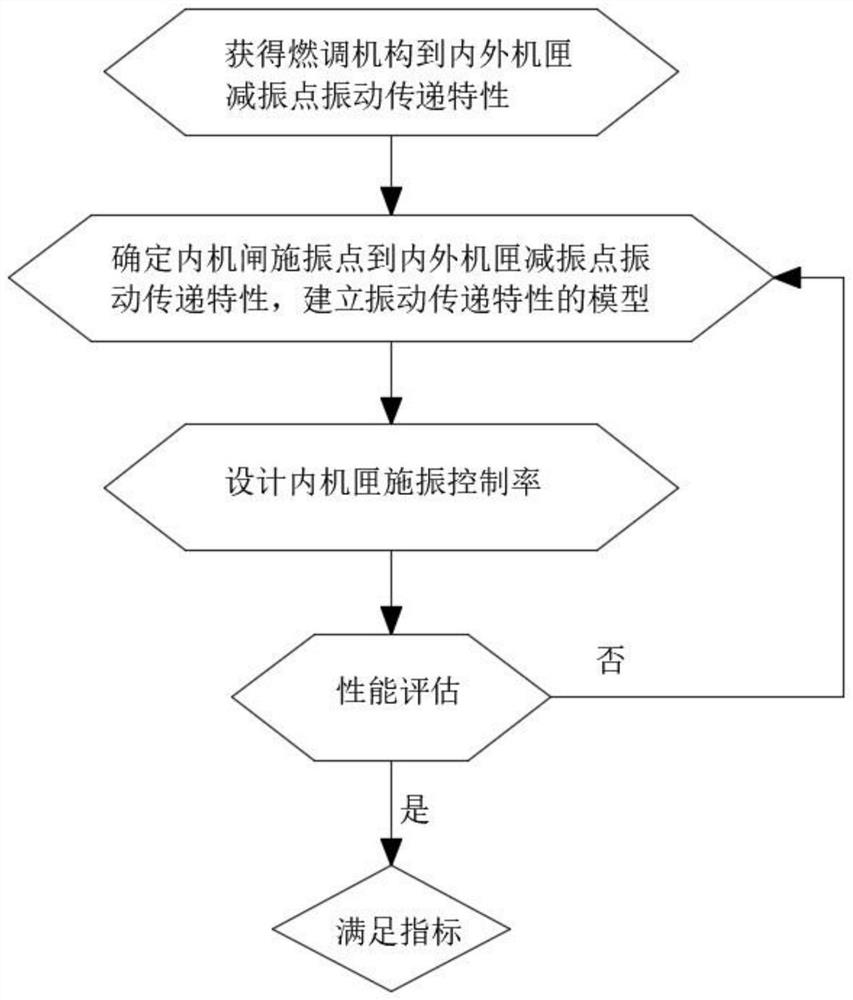

[0033]Embodiments of the present invention provide a method of damaging the air engine inside and out of the air engine in the case of a very low frequency.figure 1 As shown, including the following steps:

[0034]Step 1: The vibration transmission characteristics of the fuel adjustment mechanism to the outer miles, the vibration transmission characteristics of the fuel adjustment mechanism to the inner miles;

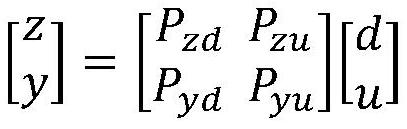

[0035]Step 2: Determine the position of the inner line, and obtain the inner cartridge, the inner miles, the vibration point vibration transmission characteristics, the inner miles of the inner cartridge, and the inner miles, the vibration point vibration transmission characteristics, establish vibration Model of passing characteristics;

[0036]Step 3: Design in the inner miles of the robe control rate;

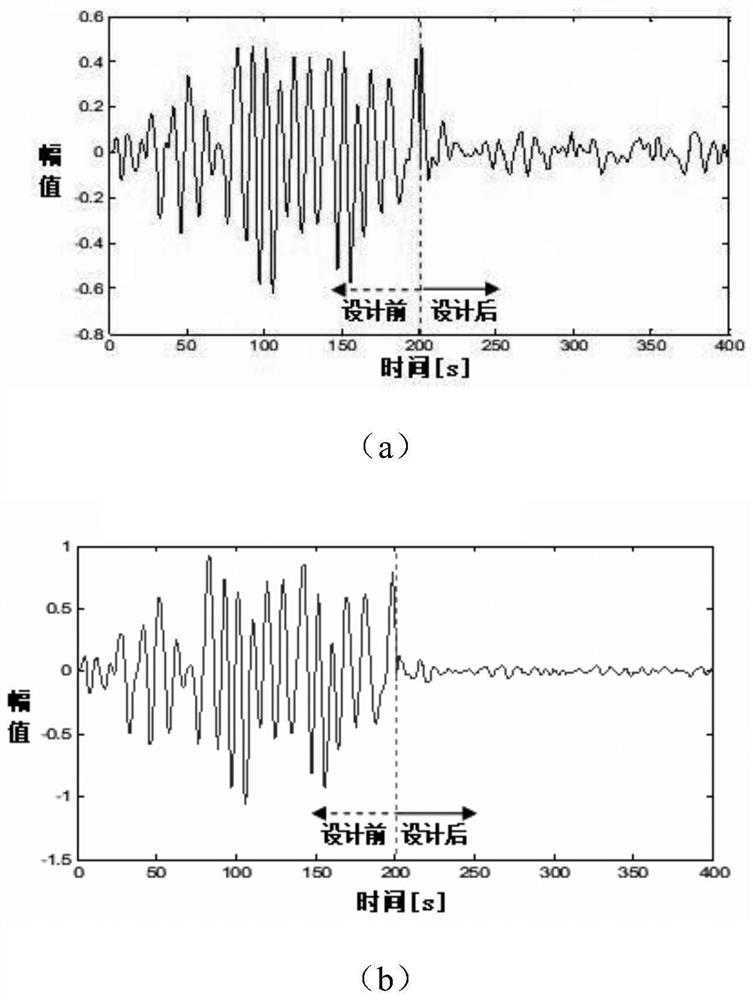

[0037]Step 4: Verify that the design in step 3 meets pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com