A strain purified silicon substrate for semiconductor quantum computation and method of forming same

A quantum computing and silicon substrate technology, applied in semiconductor/solid-state device manufacturing, nanotechnology for information processing, electrical components, etc., can solve the problems of large influence of epitaxial purified silicon and small electron mobility of purified silicon layer, etc. Achieve the effect of improving electron mobility, great research significance and economic benefits, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

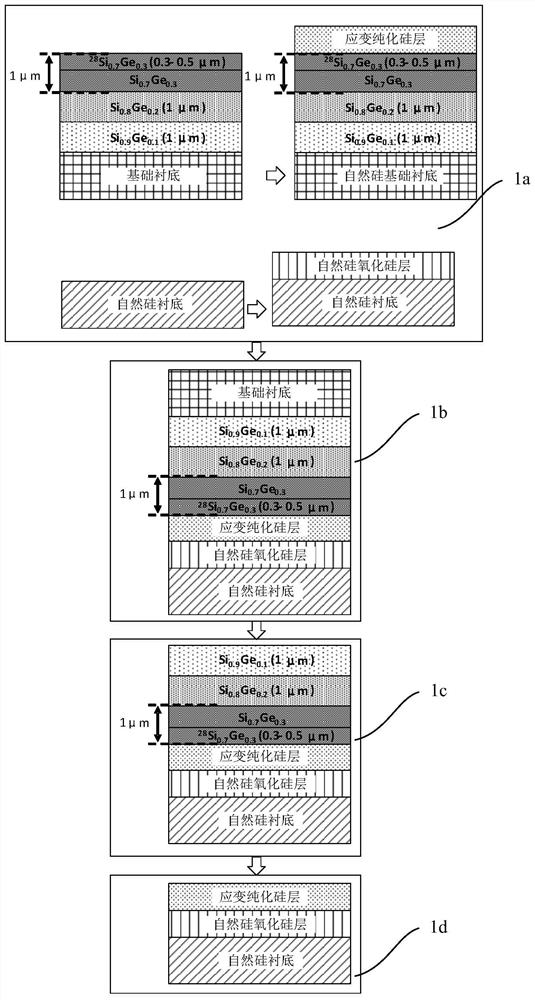

[0071] The strained purified silicon substrate in this embodiment includes a natural silicon substrate, a natural silicon oxide layer and a strained purified silicon layer stacked in sequence, see figure 1 , the specific formation method includes the following steps:

[0072] Step 1a: Provide a basic substrate, and epitaxially form four layers of silicon-germanium buffer layers on the basic substrate, which are respectively the first silicon-germanium buffer layer (Si 0.9 Ge 0.1 layer), the second silicon germanium buffer layer (Si 0.8 Ge 0.2 layer), the third silicon germanium buffer layer (Si 0.7 Ge 0.3 layer) and the fourth SiGe buffer layer ( 28 Si 0.7 Ge 0.3 layer), forming a strained purified silicon layer epitaxially on the fourth silicon germanium buffer layer to obtain a donor substrate;

[0073] Provide a natural silicon substrate, and form a layer of natural silicon oxide layer on the natural silicon substrate;

[0074] Step 1b: pressure bonding the donor s...

Embodiment 2

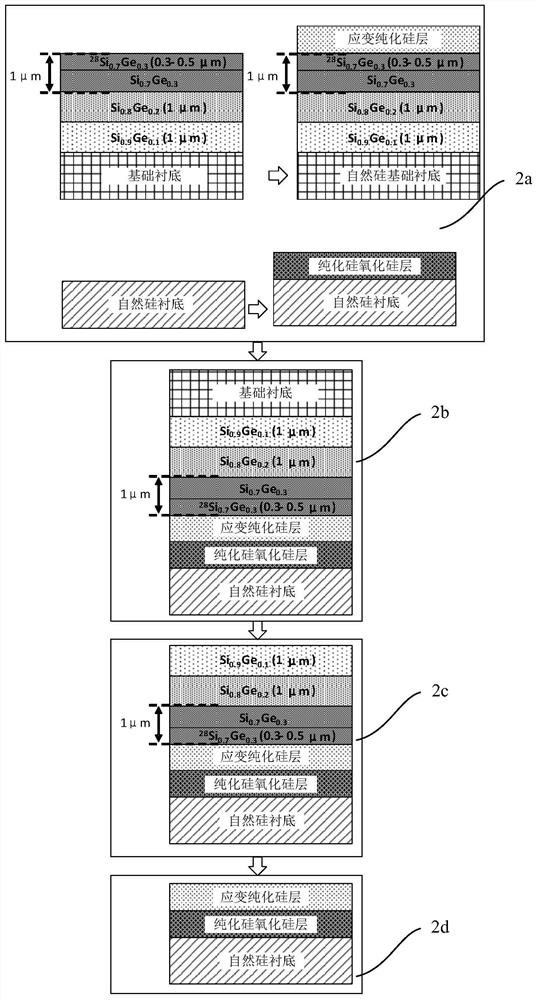

[0078] The strained purified silicon substrate in this embodiment includes a natural silicon substrate, a purified silicon oxide layer and a strained purified silicon layer stacked in sequence, see figure 2, the specific formation method includes the following steps:

[0079] Step 2a: Provide a basic substrate, and epitaxially form four layers of silicon-germanium buffer layers on the basic substrate, which are respectively the first silicon-germanium buffer layer (Si 0.9 Ge 0.1 layer), the second silicon germanium buffer layer (Si 0.8 Ge 0.2 layer), the third silicon germanium buffer layer (Si 0.7 Ge 0.3 layer) and the fourth SiGe buffer layer ( 28 Si 0.7 Ge 0.3 layer), forming a strained purified silicon layer epitaxially on the fourth silicon germanium buffer layer to obtain a donor substrate;

[0080] Provide a natural silicon substrate, and form a layer of pure silicon oxide layer on the natural silicon substrate;

[0081] Step 2b: pressure bonding the donor sub...

Embodiment 3

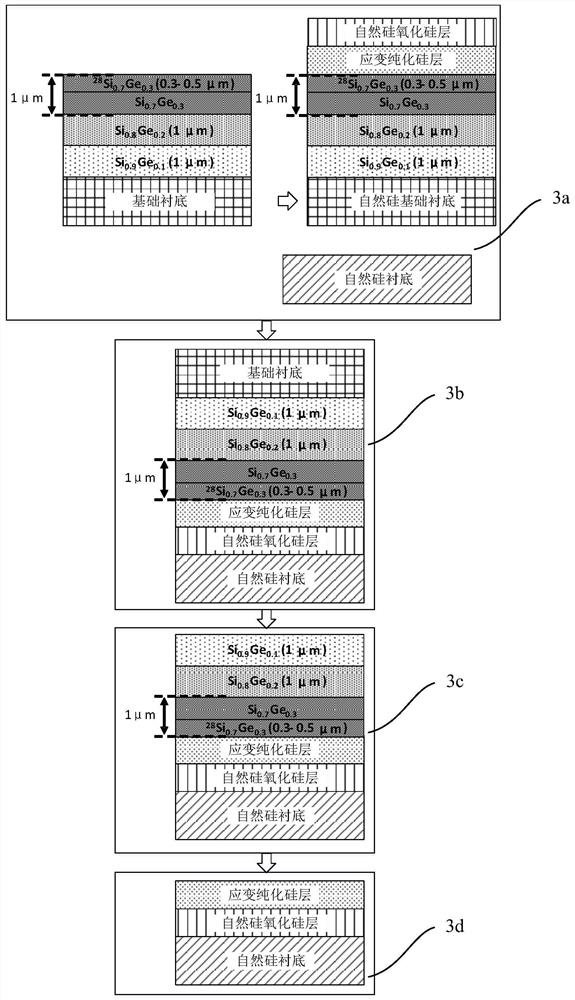

[0085] The strained purified silicon substrate in this embodiment has the same structure as the strained purified silicon substrate provided in Embodiment 1, including a natural silicon substrate, a natural silicon oxide layer and a strained purified silicon layer stacked in sequence, see image 3 , the specific formation method includes the following steps:

[0086] Step 3a: Provide a basic substrate, and epitaxially form four layers of silicon-germanium buffer layers on the basic substrate, which are respectively the first silicon-germanium buffer layer (Si 0.9 Ge 0.1 layer), the second silicon germanium buffer layer (Si 0.8 Ge 0.2 layer), the third silicon germanium buffer layer (Si 0.7 Ge 0.3 layer) and the fourth SiGe buffer layer ( 28 Si 0.7 Ge 0.3 layer), forming a strained purified silicon layer epitaxially on the fourth silicon germanium buffer layer, and forming a layer of natural silicon oxide silicon layer on the strained purified silicon layer to obtain a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com