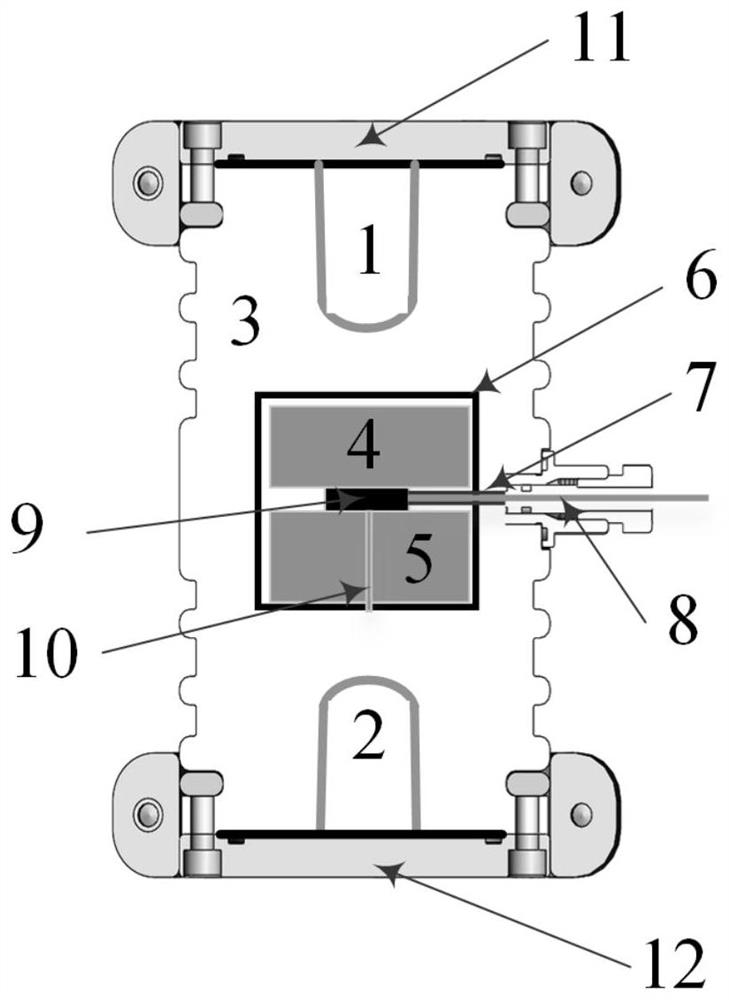

Gas switch structure based on low working coefficient and low jitter triggering

A working coefficient, gas switch technology, applied in spark gaps, electrical components, spark gaps and other directions with auxiliary triggering devices, can solve the problems of restricting the construction of large pulse power devices, unable to meet the low working coefficient of FLTD, etc., to reduce the trigger shock. The effect of wearing time delay and jitter, reducing the switching factor, and shortening the generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The FLTD is charged with positive and negative polarity, and when the discharge circuit inductor produces a nanosecondal large current pulse, when multiplexing is used in parallel, it is necessary to accurately synchronize the current pulse generation, and the power peak is superimposed.

[0045] The three-electrode field distortion gas switch is used as its main discharge branch switch, the charging voltage is ± 80kV, the high pressure pulse capacity is 100NF, and the current pulse generated by the single branch discharge is 120 ns, peak current 40kA, peak power 5GW. In order to improve the trigger consistency of the plurality of branch parallel transport, the switch structure proposed by the apparatus of the present invention can be reduced from 0.66 to 0.50, and the trigger jitter is kept within 1.5 ns, and the gas switch is effectively improved. Work reliability,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com