Continuous tea leaf enzyme-deactivating and carding machine and enzyme-deactivating method thereof

A technology for fixing stripping machine and tea leaves, which is applied in the direction of tea processing before extraction, can solve the problems of low fixing efficiency, consumption of manpower, affecting product quality, etc., and achieve the effect of improving the fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

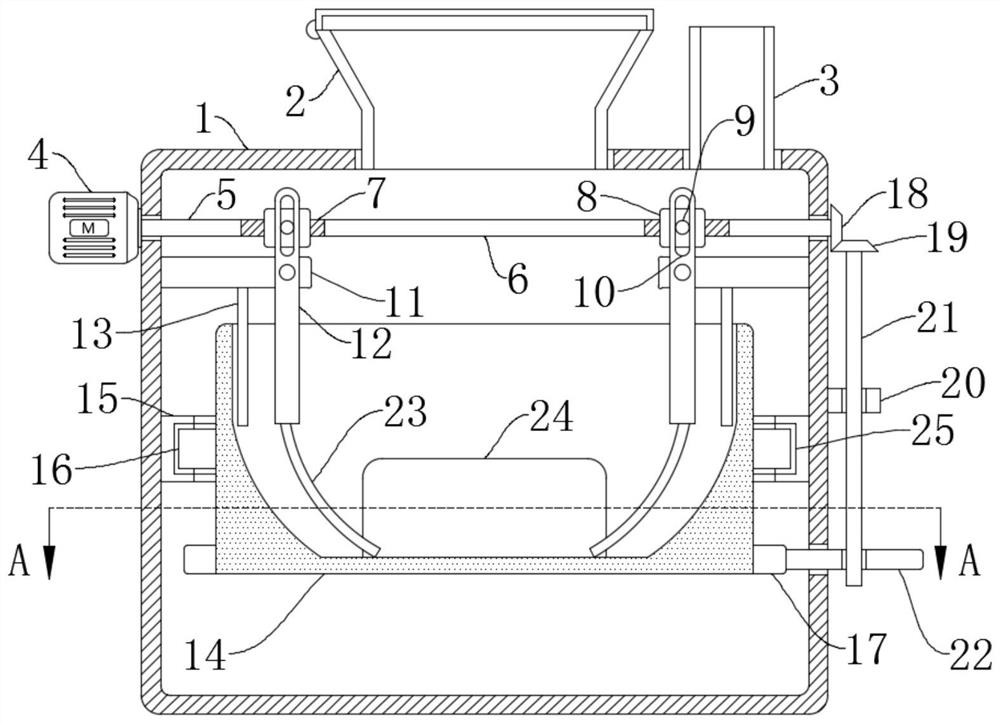

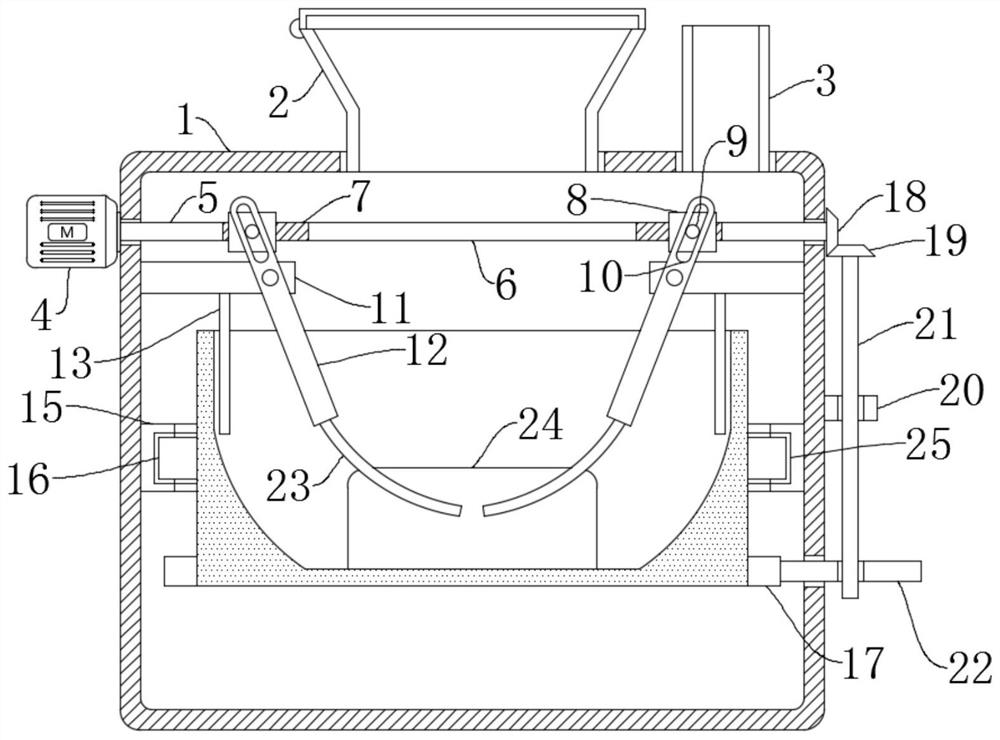

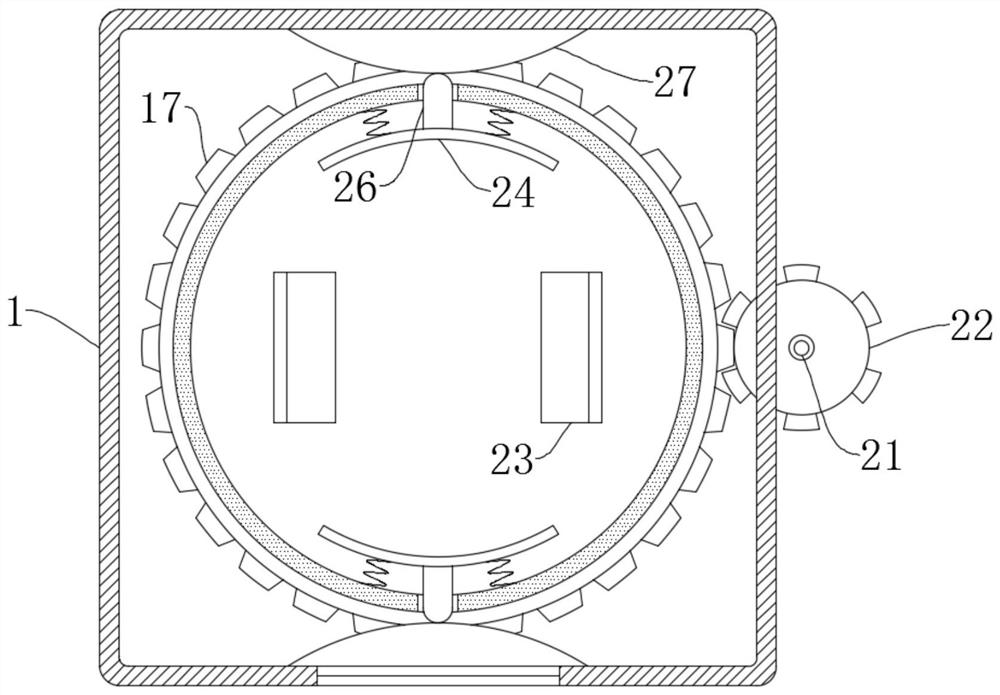

[0035]ReferFigure 1-3A continuous tea kills, including killing boxes 1, and the wall of the killing box 1 is connected to the opening, the interior wall is rotated by the hinge, and the door can be removed by opening the box, killing the tea 1 The upper wall is connected to the hopper 2, the upper hopper 2 side wall is provided with a cover, and the upper wall of the killing box 1 is connected to the air tube 3, and the inner wall of the killing box 1 is fixedly connected to the fixed block 15, and the fixed block 15 side wall is sliding The groove 25, the killing box 1 is provided with a turning shell 14, and the turning shell 14 is fixedly connected to the rotating plate 16, and the turning plate 16 is extended to the chute 25, and the turning plate 16 is in contact with the inner wall of the chute 25, and it is possible to prevent rotation The shell 14 swayed to ensure that the stability of the rotating shell 14 is rotated, and the cross section of the turning plate 16 and the fi...

Embodiment 2

[0050]ReferFigure 4 Unlike Example 1, the inner bottom portion is fixed to the inner bottom portion, and the heat transfer oil is filled in the heating box 30, and the heating box 30 is fixed to the heating rod 31, and the bottom fixed connection in the bottom of the kill box 1 The water pump 32, the water supply end of the water pump 32 is in communication with the heating tank 30, and a heat transfer tube 28 is provided in the rotating case 14, and the heat transfer tube 28 is disposed in the rotation case 14, which can greatly increase the heating area of the device, so that tea leaves The heat is well received, and the device is improved to the killing effect of the tea, and the inner wall of the killing box 1 is fixedly connected to two fixing plates 29, and the two fixing plate 29 side walls are fixedly connected to the water pipe 33 and the water pipe 34, the heat transfer tube 28 Both of which are coupled to the water pipe 33, the water pipe 34, respectively, such that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com