Flue-cured tobacco blending coloring agent as well as preparation method and application thereof

A technology for fixing agent and flue-cured tobacco, which is applied in the application, tobacco, tobacco treatment and other directions, and can solve the problems of excessive oxidation of polyphenols, production of brown pigments, and reduced quality of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

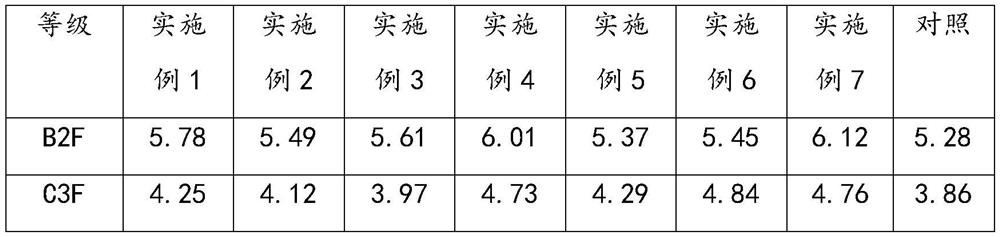

Examples

Embodiment 1

[0043] This embodiment provides a flue-cured tobacco prepared toner solution, the carrier of the solution is distilled water or tap water, and the components and concentrations are as follows:

[0044] Sodium lauryl sulfate 50g / L, vitamin C10 g / L, vitamin E10g / L, sodium sulfite 20g / L, citric acid 20g / L.

[0045] The preparation process of above-mentioned flue-cured tobacco modulation fixer solution is as follows:

[0046] 1) Dissolve 50g of sodium lauryl sulfate in 500mL of water, stir until completely dissolved, and prepare a liquid;

[0047] 2) Dissolve 10g of vitamin E in a small amount of ethanol, stir until completely dissolved, and prepare b liquid;

[0048] 3) Dissolve 20g of citric acid in 100mL of water, stir until completely dissolved, and prepare c liquid;

[0049] 4) Dissolve 10g vitamin C in 100mL water, stir until completely dissolved, and prepare d liquid;

[0050] 5) Dissolve 20g of sodium sulfite in 100mL of water, stir until completely dissolved, and prepa...

Embodiment 2

[0059] This embodiment provides a flue-cured tobacco prepared toner solution, the carrier of the solution is distilled water or tap water, and the components and concentrations are as follows:

[0060] Sodium lauryl sulfate 50g / L, vitamin C 8 g / L, vitamin E 8g / L, sodium sulfite 16g / L, citric acid 16g / L.

[0061] The method of preparing and using the flue-cured tobacco coloring agent is the same as in Example 1, and the comparison is the same amount of tap water.

Embodiment 3

[0063] This embodiment provides a flue-cured tobacco prepared toner solution, the carrier of the solution is distilled water or tap water, and the components and concentrations are as follows:

[0064] Sodium lauryl sulfate 50g / L, vitamin C14 g / L, vitamin E14g / L, sodium sulfite 28g / L, citric acid 26g / L.

[0065] The method of preparing and using the flue-cured tobacco coloring agent is the same as in Example 1, and the comparison is the same amount of tap water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com