Water floating wind driven generator built on bamboo-wound composite pressure buoyancy tank

A wind power generator and pressure technology, which is applied in the direction of wind power storage, wind power generation, wind power motors, etc., can solve the problems that are not used to remove lake water pollutants, and achieve the effects of expanding employment, protecting the ecological environment, and increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

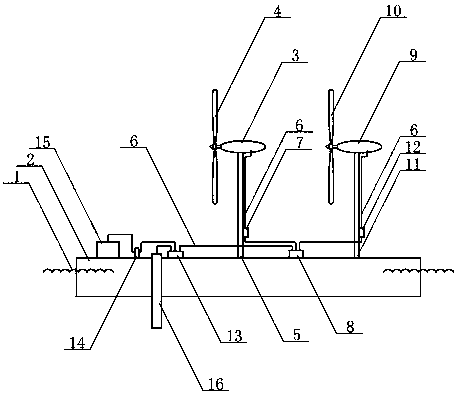

[0023] The wind power pillar armor is installed on the middle part of the upper surface of the bamboo winding composite pressure buoyancy tank, the horizontal axis wind power generator armor is installed on the top surface of the wind power pillar armor, the blade armor is installed at the front end of the horizontal axis wind power generator armor, and the wind power pillar armor is installed on the front end of the horizontal axis wind power generator armor. Wind power controller A is installed on the side of A, wind power prop B is installed on the rear portion of the upper surface of bamboo winding composite pressure buoyancy tank, horizontal axis wind power generator B is installed on the top surface of wind power prop B, and horizontal axis wind power generator B is installed on the top surface of wind power prop B. Blade B is installed on the front end of machine B, and wind power controller B is installed on the side of wind power pillar B. The wind blows blade A to rota...

Embodiment 2

[0025] The wind power pillar armor is installed on the middle part of the upper surface of the bamboo winding composite pressure buoyancy tank, the vertical axis wind power generator armor is installed on the top surface of the wind power pillar armor, and the blade armor is installed at the front end of the vertical axis wind power generator armor. Wind power controller A is installed on the side of A, wind power prop B is installed on the rear of the upper surface of the bamboo winding composite pressure buoyancy tank, vertical axis wind power generator B is installed on the top surface of wind power prop B, and vertical axis wind power generator B is installed on the top surface of wind power prop B. Blade B is installed on the front end of B, and wind power controller B is installed on the side of wind power pillar B. The wind blows blade A to rotate and drives the current generated by vertical axis wind power generator A to enter the smart confluence through conductive wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com