Carbon dioxide electrolytic device and method for electrolyzing carbon dioxide

A carbon dioxide and electrolysis device technology, applied in the electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of the deterioration of the output of the electrolysis cell, the increase of the voltage of the electrolysis cell, and the reduction of the CO generation amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

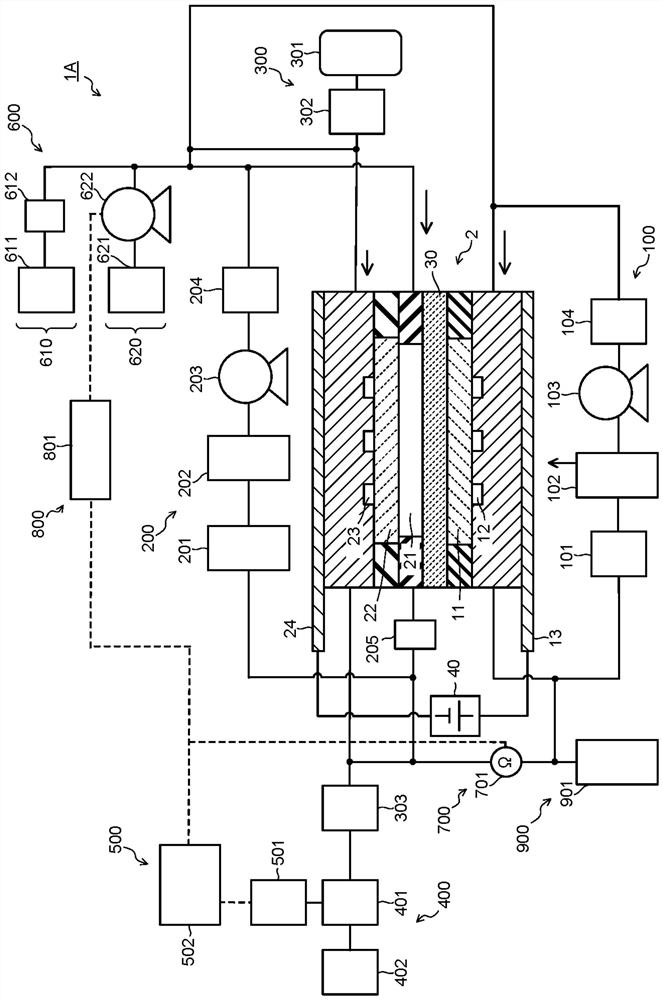

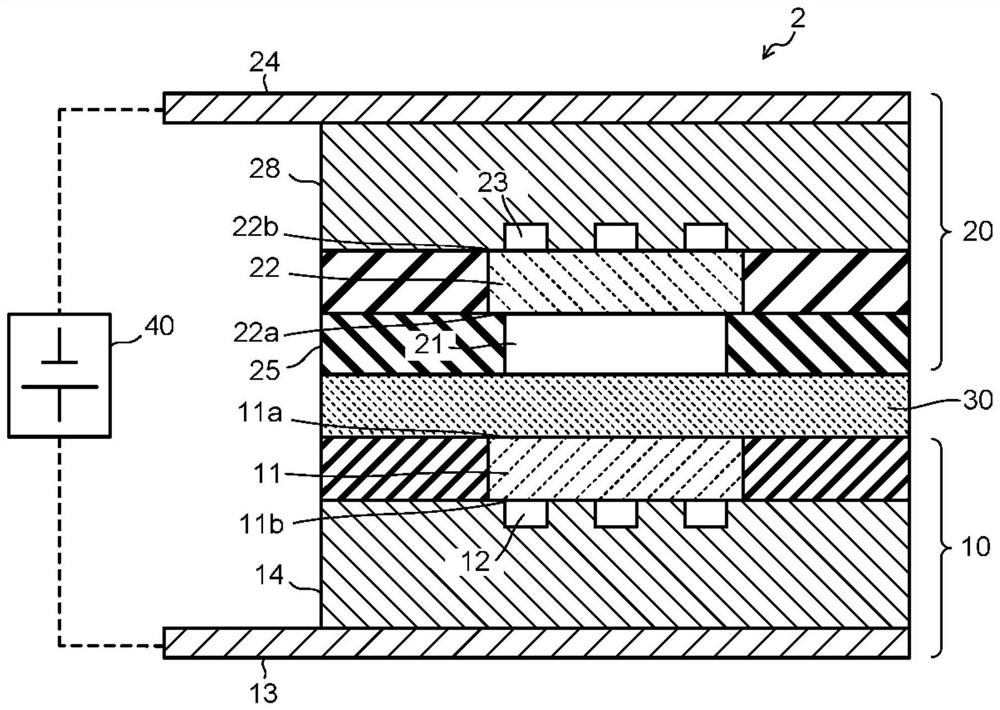

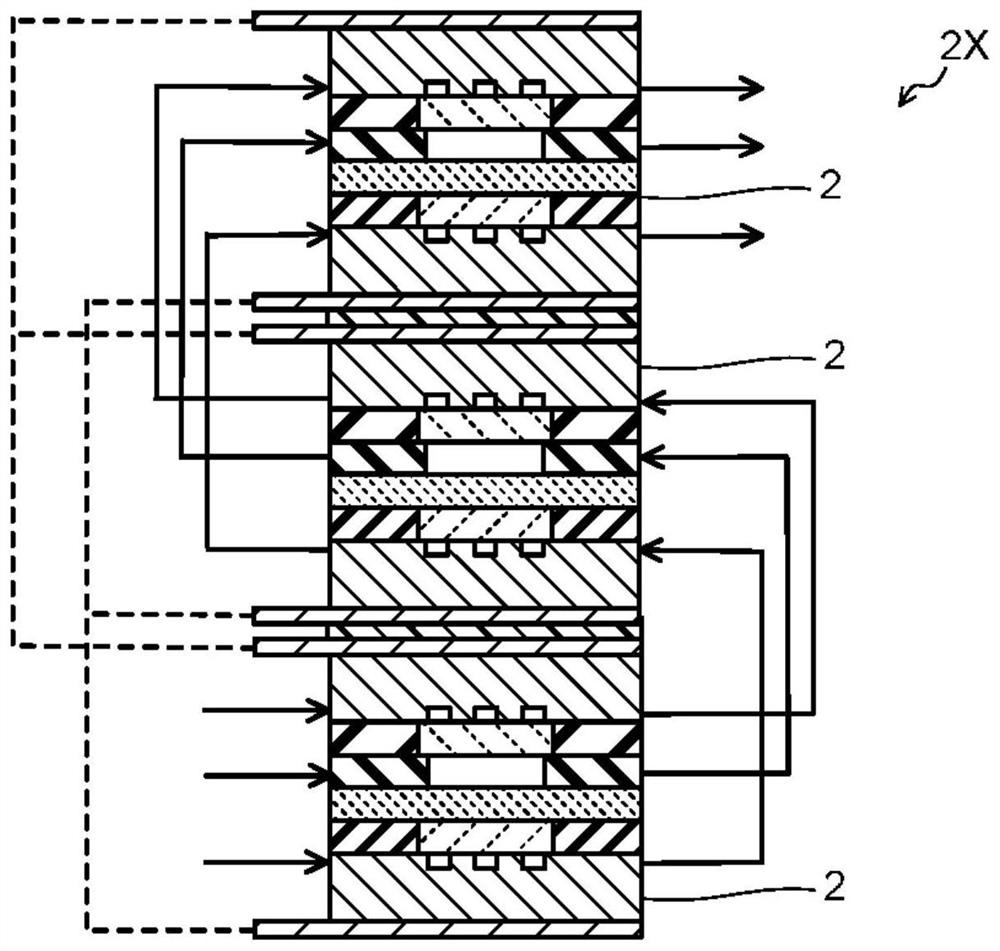

[0029] figure 1 It is a figure which shows the structure of the electrolysis apparatus 1 (1A) of the carbon dioxide of the 1st embodiment, figure 2 with image 3 is showing figure 1 A cross-sectional view showing the configuration of the electrolytic cell in the electrolytic device shown. figure 1 The illustrated carbon dioxide electrolysis device 1A includes: an electrolytic cell 2, an anolyte solution supply system 100 for supplying an anolyte solution to the electrolytic cell 2, a cathodic solution supply system 200 for supplying a cathodic solution to the electrolytic cell 2, and a system for supplying carbon dioxide gas to the electrolytic cell 2. The gas supply system 300, the product collection system 400 for collecting the product generated by the reduction reaction of the electrolytic cell 2, the electrolytic operation control system 500 for detecting the reducing performance from the collected product and controlling the electrolytic operation of the electrolytic ...

no. 2 Embodiment approach

[0064] Image 6 It is a figure which shows the structure of the electrolysis apparatus 1B of carbon dioxide of 2nd Embodiment. Image 6 The illustrated carbon dioxide electrolysis device 1B has a pipe for supplying the flushing liquid to the electrolytic cell 2 from the flow rate regulator (pump) 622 of the flushing liquid supply part 620 to the configuration of the carbon dioxide electrolysis device 1A of the first embodiment. The second conductivity meter 702 for measuring the conductivity of the flushing liquid before being introduced into the electrolytic cell 2 on the inflow port side of the flushing liquid supply line to the electrolytic cell 2 is basically the same as that of the carbon dioxide in the first embodiment. The electrolysis device 1A is the same. Like the first conductivity meter 701, the second conductivity meter 702 is electrically connected to the data collection and control unit 502 and the recovery operation control unit 801, and is controlled by the r...

no. 3 Embodiment approach

[0071] Figure 8 It is a figure which shows the structure of the electrolysis apparatus 1C of carbon dioxide of 3rd Embodiment. Figure 8 The carbon dioxide electrolysis device 1C shown in the second embodiment has an AC resistance meter 703 for measuring the impedance of the electrolytic cell 2 and an AC resistance meter 703 for measuring the impedance of the anode solution circulating in the anode solution supply system 100 are added to the configuration of the carbon dioxide electrolysis device 1B of the second embodiment. Electrolyte concentration measuring instrument 105 for electrolyte concentration, and measuring CO circulating in the electrolytic cell 2 2 The flow meter 304 for the flow rate of gas is basically the same as that of the carbon dioxide electrolysis device 1B of the second embodiment except for the configuration. The AC resistance meter 703 is the same as the first and second conductivity meters 701 and 702, and is electrically connected to the data colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com