Molybdenum ore tailing sand reinforcing and anti-seepage method and building structure

A technology for tailings sand and anti-seepage, applied in construction, infrastructure engineering, excavation, etc., can solve the problems of high dam failure risk, inability to eliminate or reduce the risk of heavy metal pollution, etc., to reduce heavy metal pollutants, save resources and energy. , the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

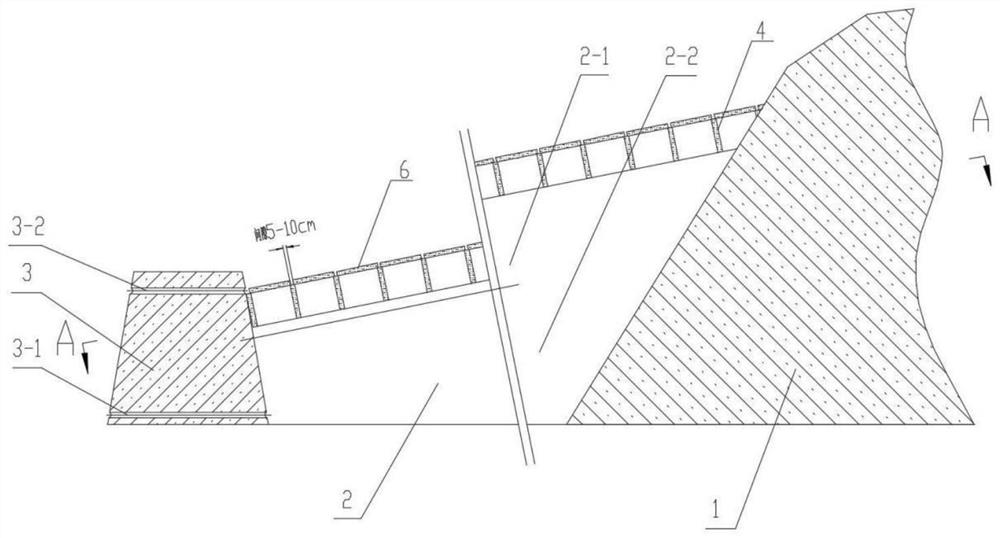

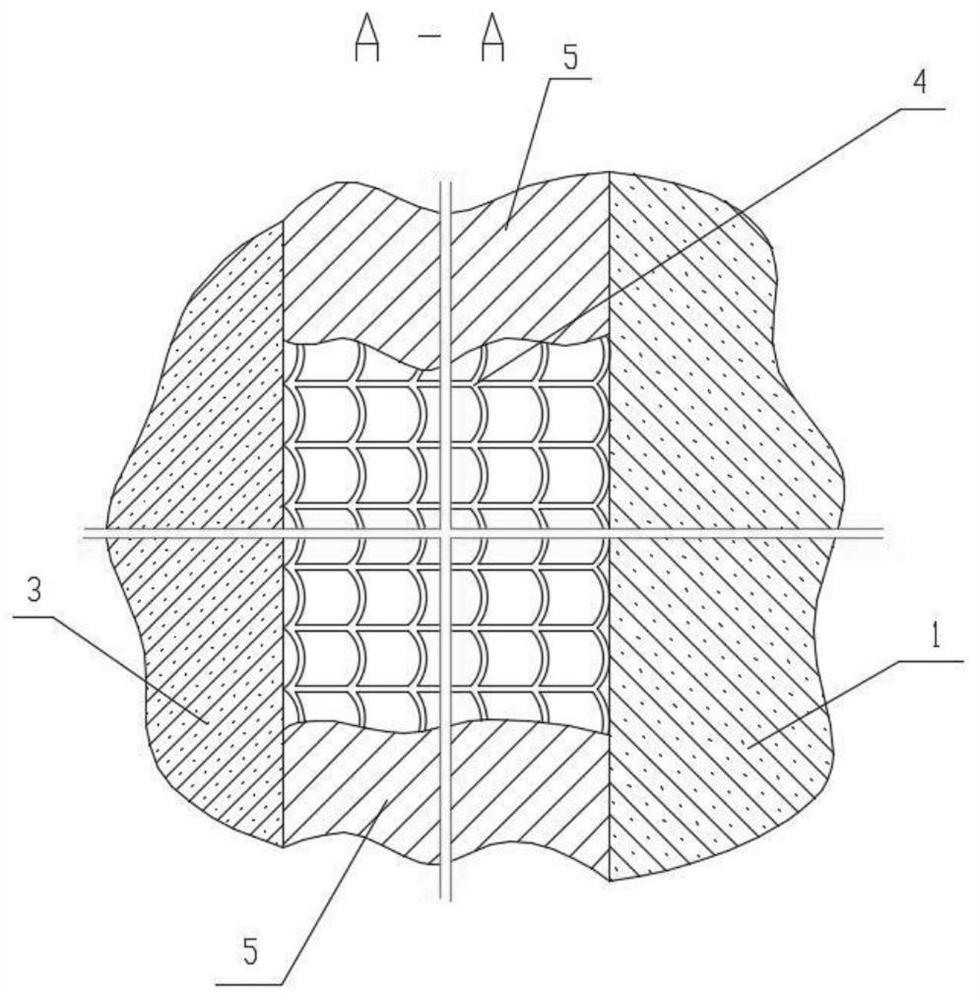

[0032] A reinforcement and anti-leakage method for molybdenum ore tailings, which uses the canyon formed by the mine mountain and side mountains to stack the molybdenum ore tailings along the slope of the canyon, and a tailings dam for blocking the tailings is built in the downstream of the canyon. Enclose the entire tailings, and open a drainage hole on the tailings dam, divide the tailings sand into two parts: the powder surface layer and the powder base layer, and use an auger drilling machine to drill on the powder surface layer, and the drilling depth reaches the powder In the body base, the screw conveying mechanism of the auger drilling machine outputs the excavated tailings powder, and at the same time fills the drilled gap with curing agent slurry through the curing agent slurry delivery pipe at the rear end of the screw conveying mechanism. It has a grid structure, and the grid-like mineral powder solidification wall is formed after the curing agent slurry is solidifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com