Light beam drift compensation device without mechanical structure and implementation method thereof

A drift compensation, non-mechanical technology, applied in the field of optical communication and atmospheric optics, can solve the problems of demodulation failure, low response rate, short life, etc., achieve the effect of reducing algorithm complexity, no need for photoelectric conversion, and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

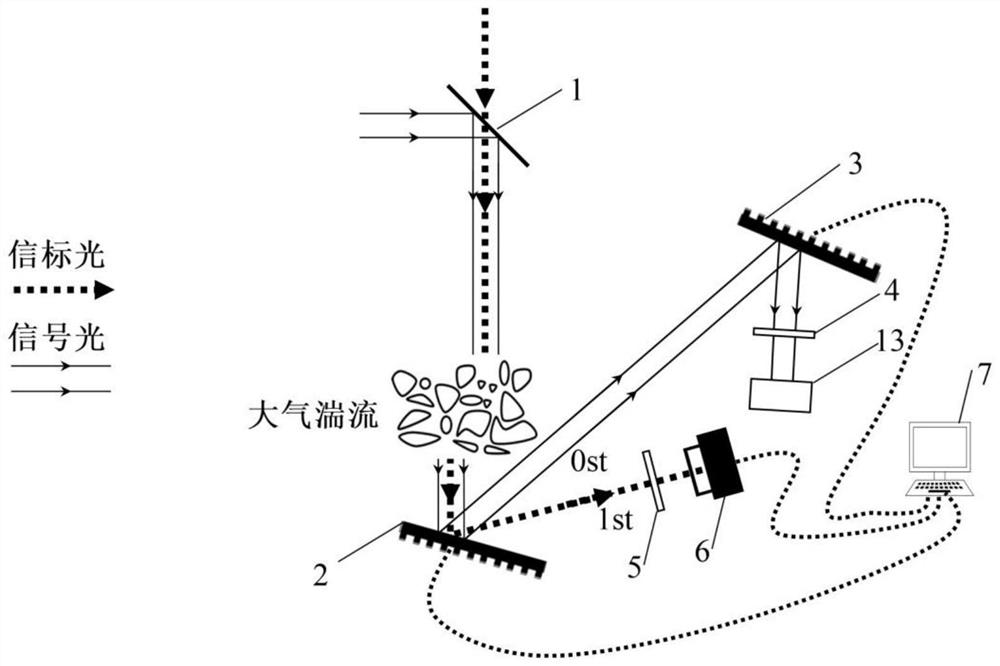

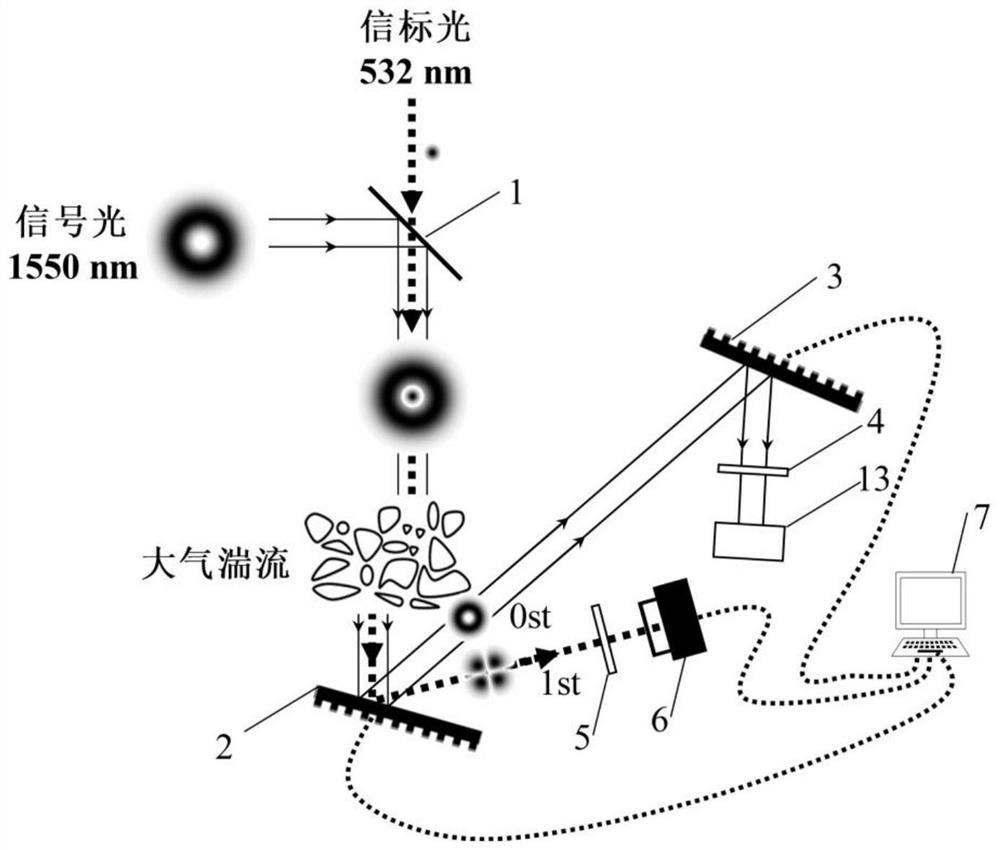

[0061] refer to image 3 As shown, it is a schematic diagram of Embodiment 1 of a beam drift compensation device without a mechanical structure. Based on the response of the spatial light modulator to different wavelengths, this embodiment provides a beam drift compensation device without a mechanical structure. The device comprises a dichroic mirror 1, a first spatial light modulator 2, a phase hologram 201, a blazed grating hologram 202, a second spatial light modulator 3, a first optical filter 4, a second optical filter 5, CCD camera 6 , computer 7 and signal receiving unit 13 . Wherein, the first spatial light modulator 2 and the second spatial light modulator 3 are placed in parallel.

[0062] The dichroic mirror 1 is used to coaxially combine the signal light and the beacon light, and the first spatial light modulator 2 is loaded with a phase hologram 201 and a blazed grating hologram 202 for modulating the beacon light and combining the beacon light Light and signal ...

Embodiment 2

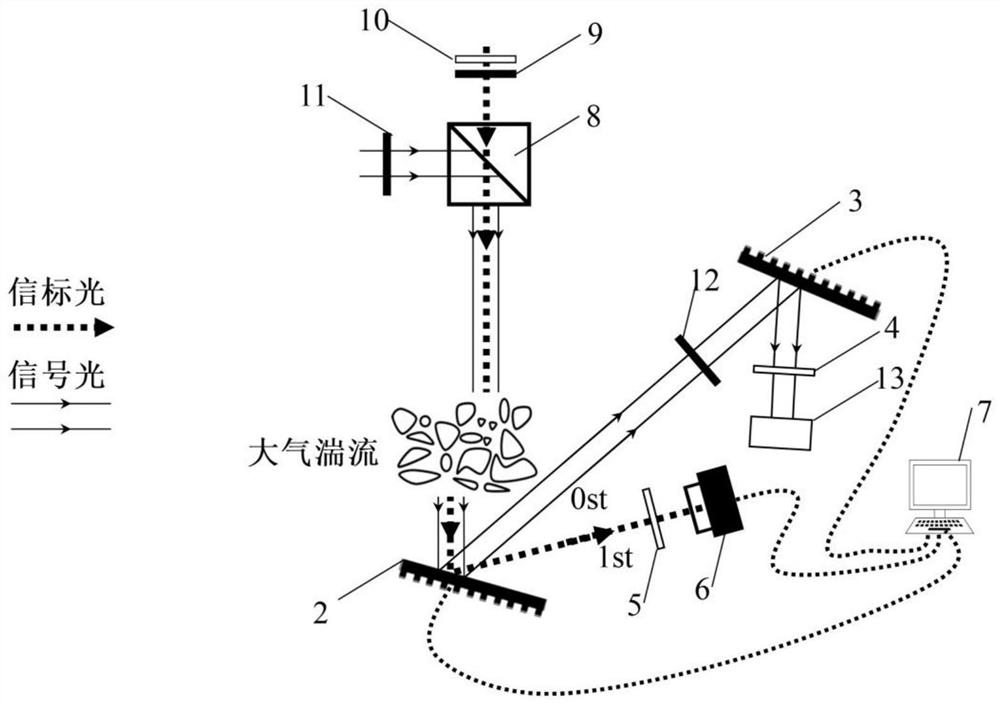

[0074] refer to Figure 7 Shown is a schematic diagram of Embodiment 2 of a beam drift compensation device without a mechanical structure. The difference between this device and the first embodiment is that the second embodiment is based on the response of the spatial light modulator to different polarization states to realize the spatial separation of the beacon light and the signal light, so it is necessary to change the dichroic mirror 1 in the first embodiment to Beam combiner 8, and add optical elements for adjusting the polarization state of incident signal light and beacon light: polarizer 10, first half-wave plate 9, second half-wave plate 11, third half-wave plate 12. The polarizer 10 and the first half-wave plate 9 are placed in parallel, the beacon light enters the beam combiner 8 through the polarizer 10 and the first half-wave plate 9, the signal light enters the beam combiner 8 through the second half-wave plate 11, and the third The half-wave plate 12 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com