Wind turbine generator maintenance work quality examination auxiliary method and system

A work quality, wind turbine technology, applied in relational databases, computer parts, structured data retrieval, etc., can solve problems such as inability to compare a large number of pictures in a short time, labor and time cost, low accuracy, etc. Facilitate intuitive analysis, reduce manual confirmation, and achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

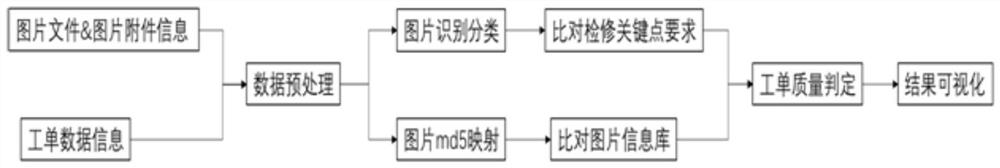

[0055] This embodiment discloses an auxiliary method for reviewing the quality of wind turbine maintenance work. The method is to synchronize the acquisition of picture data information and work order data, and take all pictures in a work order as an analysis unit, and input each picture In the image recognition and classification model that has been trained, the model gives the classification category and confidence probability. At the same time, each picture is mapped to md5 information, and the picture name and mapping information are saved to the database for repeated comparisons. Finally, according to the regular inspection According to the requirements of the specification, the quality of the maintenance work order is judged whether it is qualified or not, and the results are visualized.

[0056] Such as figure 1 As shown, the above-mentioned wind turbine overhaul work quality review auxiliary method in this embodiment includes the following steps:

[0057] 1) Image dat...

Embodiment 2

[0072] This embodiment discloses an auxiliary system for reviewing the quality of wind turbine maintenance work. The system uses deep learning image recognition technology to identify key points of maintenance, and uses encryption function mapping to identify reused pictures, such as Figure 4 As shown, the system is divided into a background data processing and analysis module and a front-end interface display and operation module, of which:

[0073] The background data processing analysis module includes the following functional units:

[0074] In order to reduce the impact of the system on network bandwidth, the timing task unit starts its analysis program at 4:00 every morning, and completes the tasks of image data synchronization, work order data synchronization, image data analysis, and work order quality judgment in sequence; of course, the program also The execution cycle can be set.

[0075] The data synchronization unit adopts the incremental update method to synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com