Digital detection and inspection system for coal

An inspection system and coal technology, applied in manufacturing computing systems, office automation, data processing applications, etc., can solve the problems of many human intervention factors, lack of an integrated information platform for coal quality inspection, and extensive on-site management, so as to reduce labor costs. and economic costs, improve work quality and efficiency, and achieve the effect of effective regulation and supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

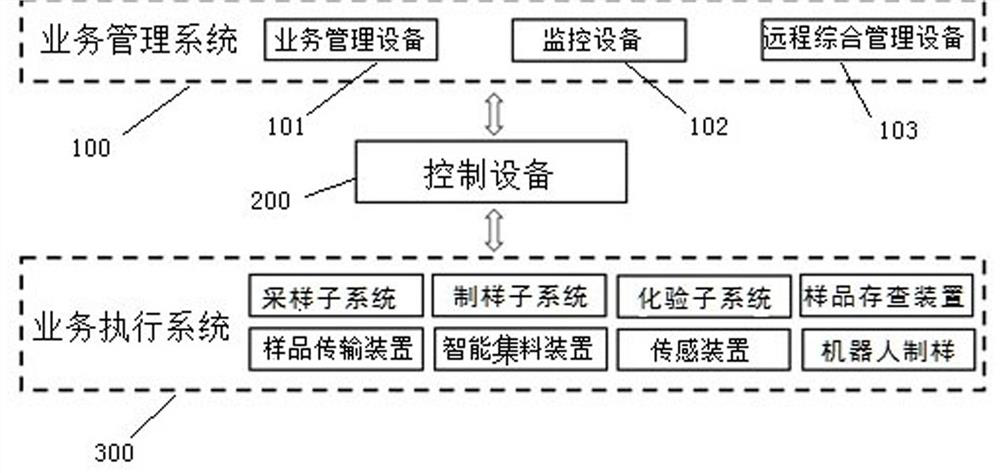

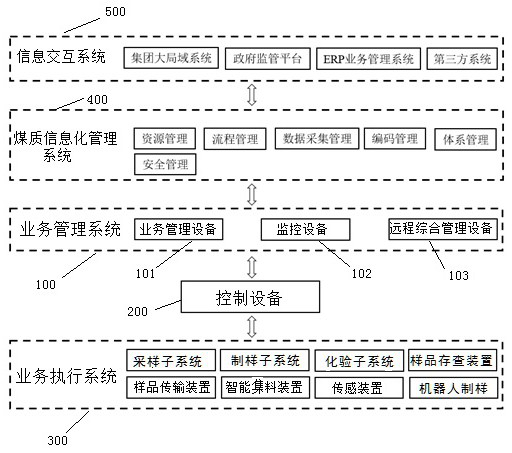

[0029] Coal quality detection has the characteristics of multiple coal types, large batches, complex processes, many uncertain factors in sampling and preparation, high precision requirements, and strong detection timeliness. It belongs to a typical discrete production process. In view of this feature, the embodiment of the present invention provides a coal digital detection and inspection system, which utilizes informatization and digital technology to construct a coal quality detection system that integrates mining, production, drive and execution, unattended, and fully automatic operation. link, planning, managing, diagnosing, and optimizing the process to achieve streamlined testing, paperless process, no data landing, and traceable traces, so as to meet the basic requirements of intelligent testing.

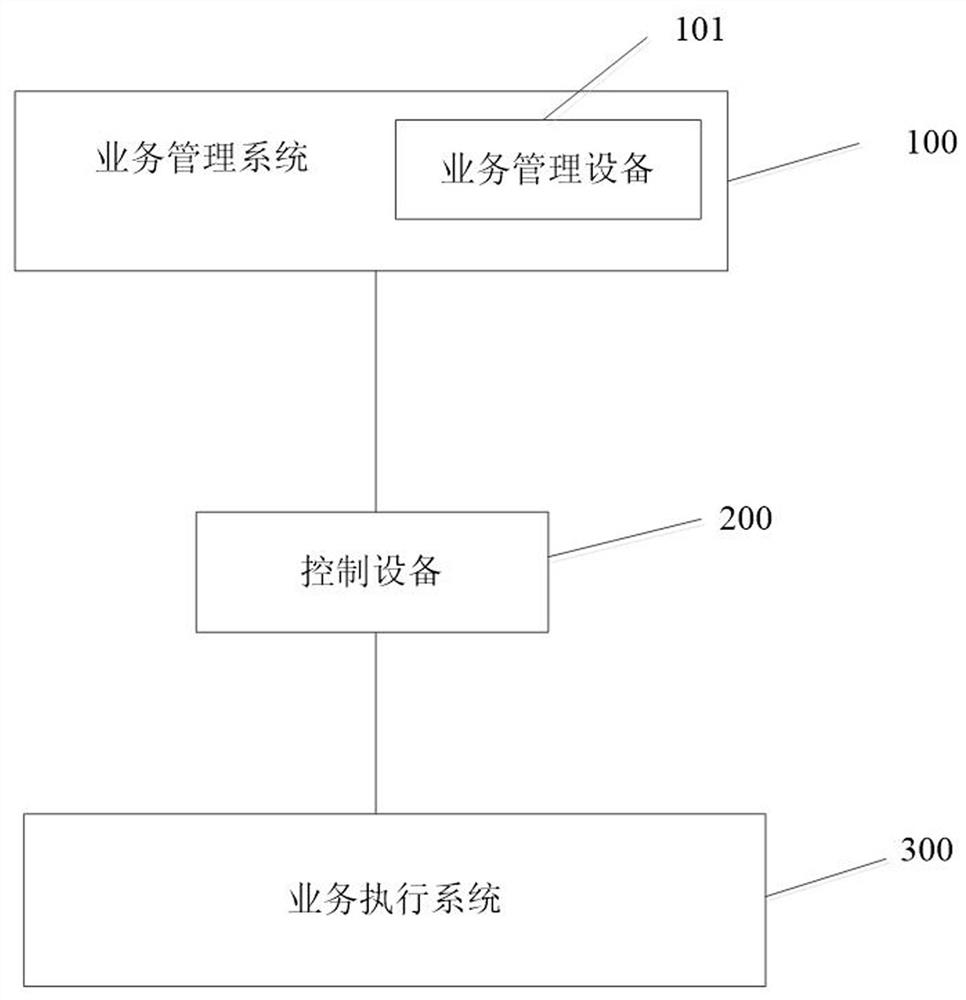

[0030] Such as figure 1 As shown, it is a schematic diagram of the architecture of a coal digital detection and inspection system provided by the embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com