Tail gas treatment system for chemical production

A technology for exhaust gas treatment and chemical production, which is applied in the direction of air quality improvement, the use of liquid separation agents, chemical instruments and methods, etc., can solve the problems of increasing treatment costs, single structure, and low utilization rate of spray liquid, and achieves improved utilization. efficiency, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

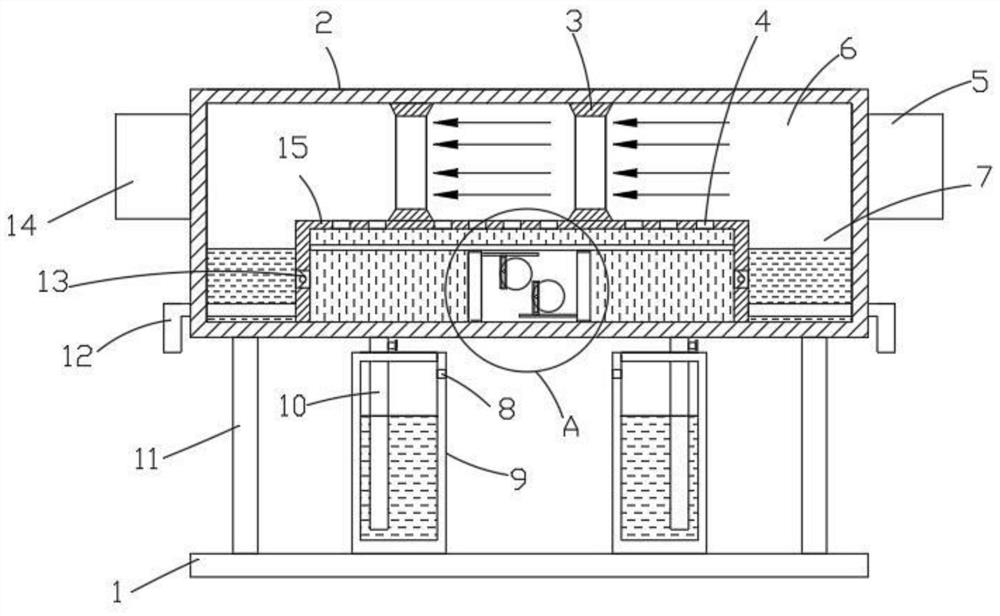

[0028] see Figure 1-4 , a chemical production tail gas treatment system, comprising a substrate 1, a processing box 2 fixed above the substrate 1, the opposite sides of the processing box 2 are respectively provided with an inlet pipe 5 and an outlet pipe 14.

[0029] The inner bottom of the treatment box 2 is provided with an inner shell 15 , and a treatment chamber 6 through which waste gas circulates is formed between the outer side of the inner shell 15 and the inner wall of the treatment box 2 . The bottom of the treatment chamber 6 has at least one liquid accumulation area 7 .

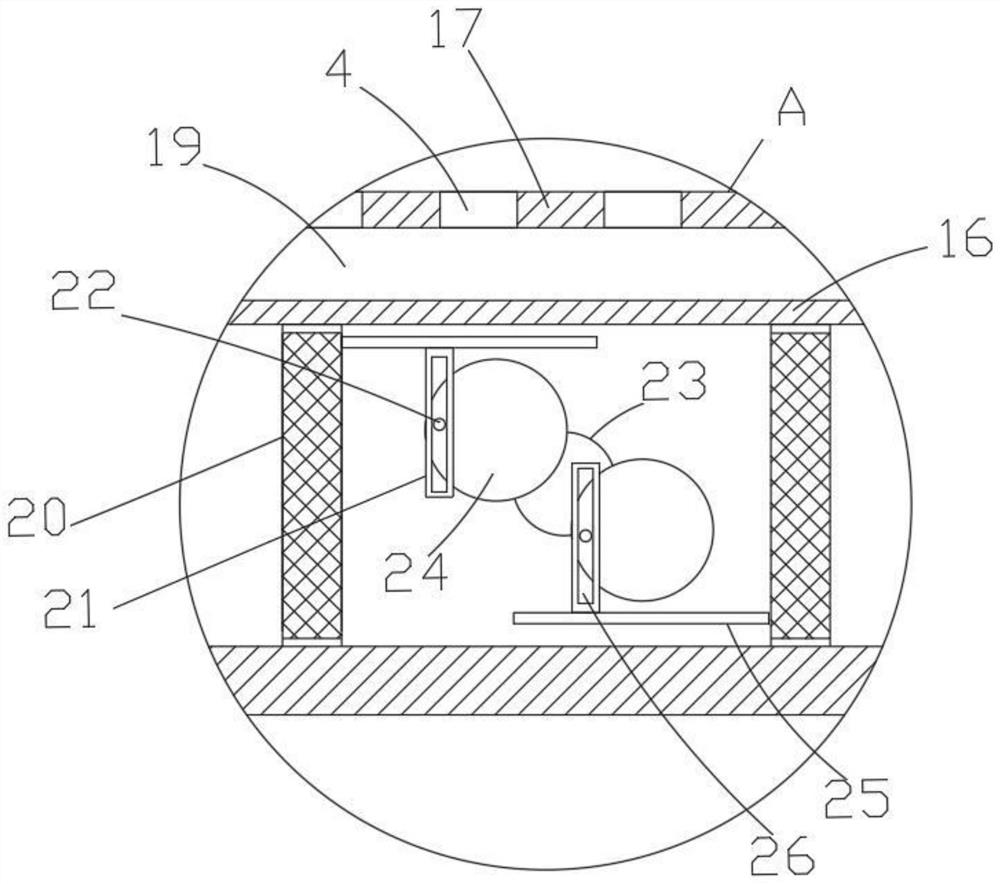

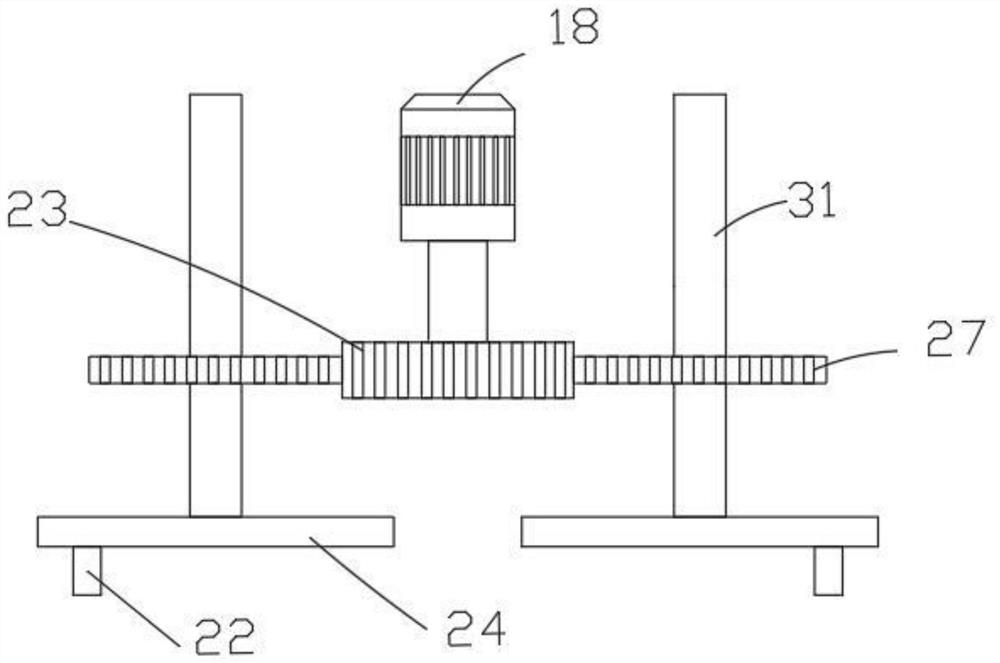

[0030] The inner partition 16 is fixed inside the inner casing 15, the liquid storage chamber 19 is formed between the inner partition 16 and the top shell of the inner casing 15, and the liquid replenishment chamber is formed between the inner partition 16 and the bottom casing of the inner casing 15, and the Two push plates 20 are arranged symmetrically in the liquid replenishing chamber, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com