Cigarette packaging production line

A packaging production line and cigarette technology, which is applied in the direction of packaging cigarettes, etc., can solve the problems of difficult parallel belts, troublesome operation, complex transmission system, etc., and achieve the effects of reducing the difficulty and cycle of assembly and debugging, convenient installation or disassembly, and stable and uniform air source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] see Figure 1 to Figure 22 , a cigarette packaging production line involved in the present invention, including environmental protection paper fixed folding device 1, aluminum foil paper short side fixed folding device 2, aluminum foil paper synchronous conveyor belt 3, inner frame paper pneumatic clamping device 4, aluminum foil paper Alloy channel 5 and channel corner gearbox 6;

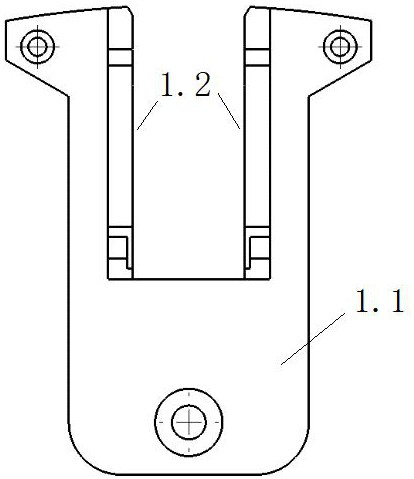

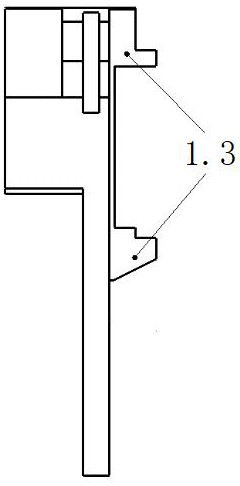

[0058] The environmentally friendly paper fixing and folding device 1 includes a No. 2 wheel mold box 1.1, a paper-supporting bump 1.3 and a working surface 1.2, and the paper-supporting bump 1.3 is arranged on the upper and lower sides of the working surface 1.2 of the No. 2 wheel mold box 1.1 At both ends, the paper-supporting bump 1.3 plays the role of lining when the first short side is folded;

[0059] The short side fixed folding device 2 of the aluminum foil paper is installed on the transition channel plate between the second wheel 7 and the third wheel, and the short side fixed fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com