Alkali-activated clinker-free refractory self-leveling concrete and preparation method thereof

A self-leveling concrete, clinker-free technology, applied in the field of building materials, can solve the problems of increased raw material cost, high consumption of materials, and high technical requirements, and achieves the advantages of promoting compressive and flexural strength, preventing puncture, and improving volume stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

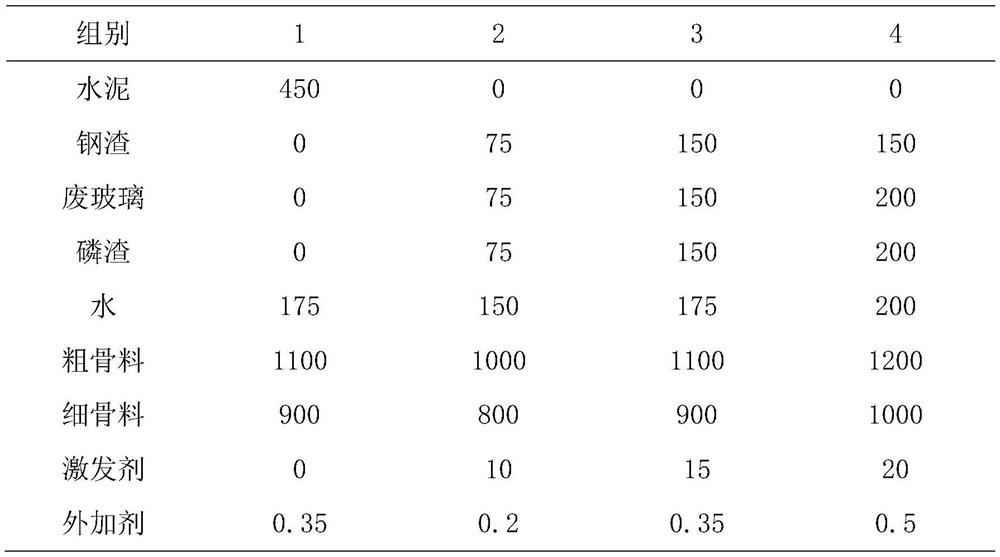

[0027] Embodiment 1——control group:

[0028] Take 450 parts of cement, 175 parts of water, 1100 parts of fine aggregate, 900 parts of coarse aggregate, and 0.35 parts of admixture by mass and stir in proportion to obtain concrete;

Embodiment 2-4

[0029] Embodiment 2-4 is some embodiments of the present invention:

Embodiment 2

[0031] (1) Take a certain amount of steel slag, waste glass, and phosphorus slag and send them into the crusher respectively for crushing until the average particle diameter is 20-50 μm;

[0032] (2) Take a certain number of copper tailings and send them into the ball mill, and sieve to obtain coarse aggregates with an average particle diameter of 8-10mm; fine aggregates with an average particle diameter of 3-4.75mm;

[0033] (3) Send the three broken materials obtained in step (1) into the wet ball mill respectively. Add water according to the weight ratio of water to material 0.5-0.6, then add 1-5 parts of grinding aid, ball mill for 1-2 hours, and ball-mill steel slag, waste glass and phosphorus slag respectively until the average particle diameter is 6-10μm, 3- 5μm, 1-5μm, get three kinds of slurry respectively;

[0034] (4) The three kinds of slurries obtained in step (3) are mixed according to 75 parts of steel slag, 75 parts of waste glass and 75 parts of phosphorus sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com