Wort film enhanced mass transfer boiling system and low-heat load boiling process thereof

A technology of wort and thin film, which is applied in the wort boiling system and its technology field, can solve the problems of high heat load, reduce heat load in the precipitation stage, and high heat load in the boiling stage, so as to reduce volatilization loss, reduce heat load, and reduce TBA value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

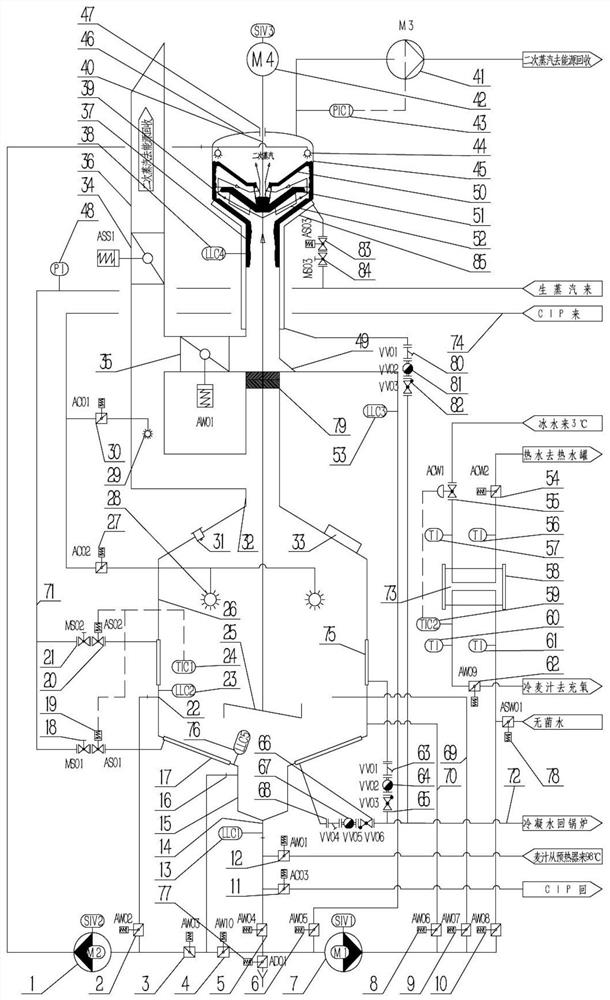

[0037] A wort film enhanced mass transfer boiling system, including a boiling sedimentation tank body 26, a centrifugal film forming enhanced mass transfer device 45, a steam inlet pipeline system 71, a steam outlet pipeline system 72, a frequency conversion material pump 7, and a steam outlet pipeline system 72. No. frequency conversion material pump 1, wort cooling system 73 and CIP system 74.

[0038] Centrifugal film forming enhanced mass transfer device 45 is provided with film forming device housing 46, liquid level switch 4 38, mechanical seal 47, rotating shaft 40, frequency conversion motor 42, pressure sensor 43, wort buffer cylinder 37, outlet 49 and liquid distribution device 44. A gravitational field diaphragm 50 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com