Single-channel multilayer coil pipe type phase change heat storage device

A phase-change heat storage and coil-type technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as uneven temperature distribution of heat storage devices, and achieve easy distributed application promotion, The effect of high device integration and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

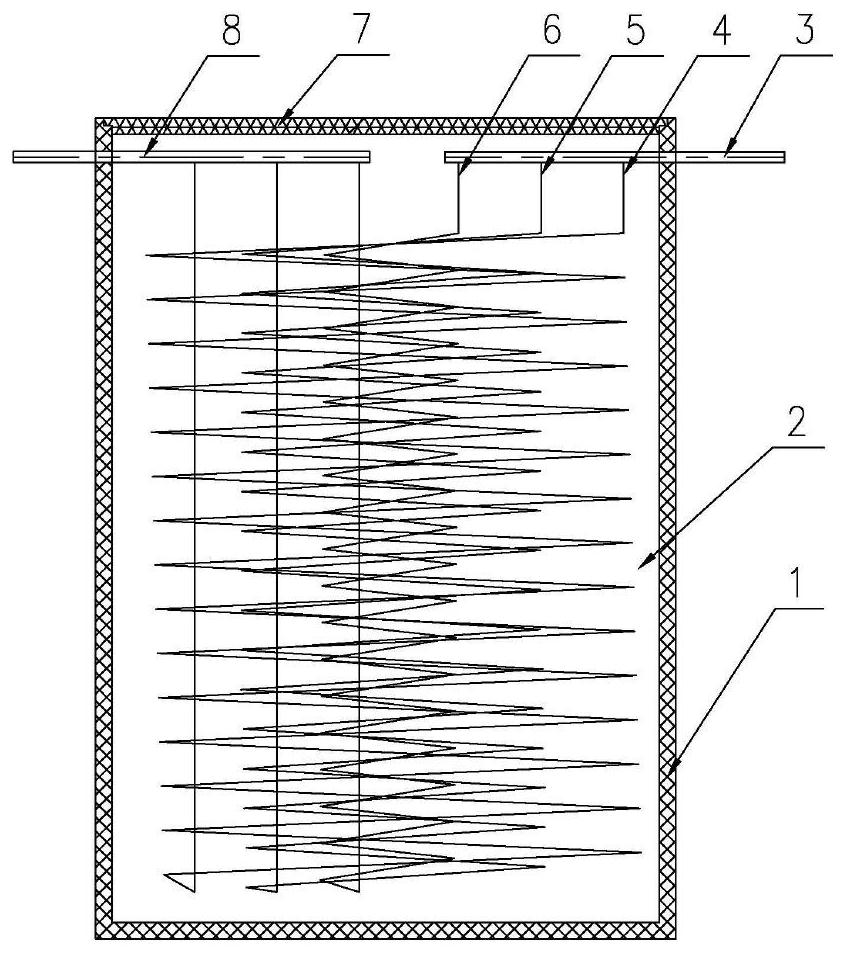

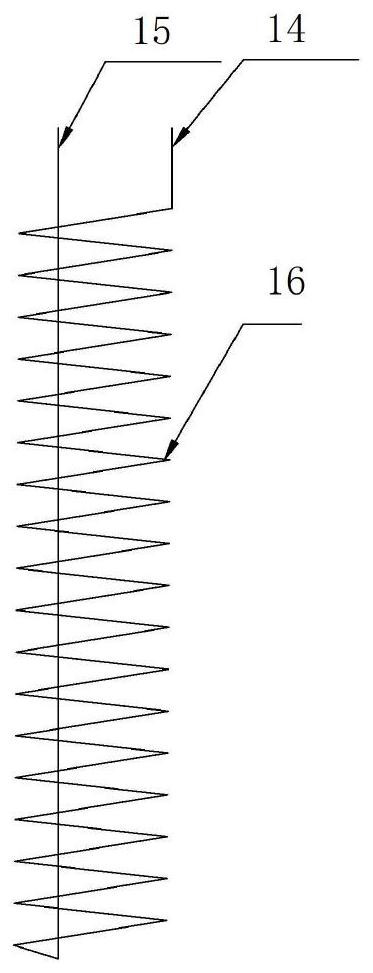

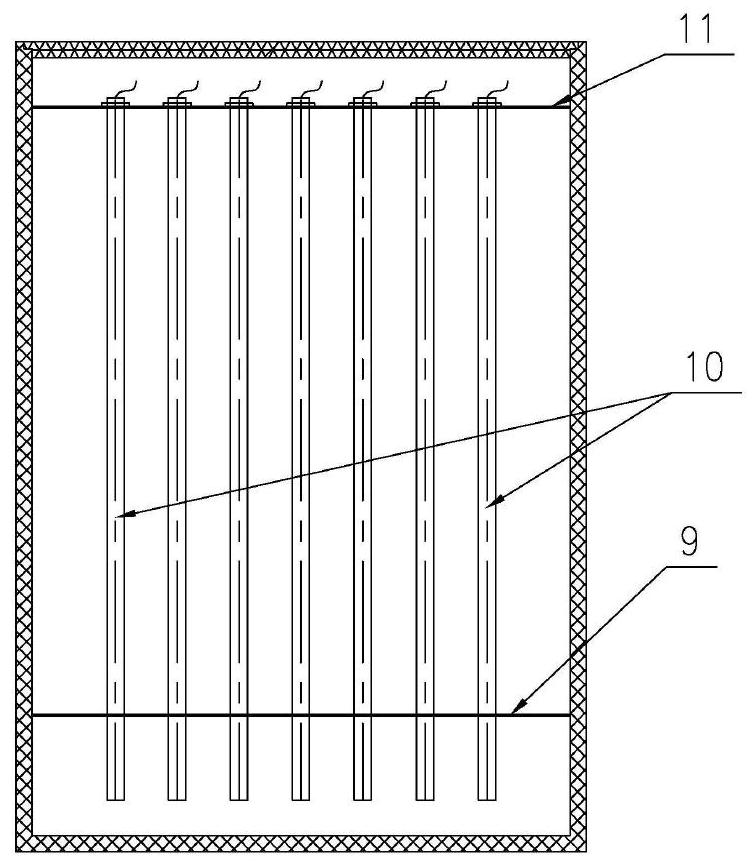

[0049] A single-channel multi-layer sleeve coil type phase change heat storage device, mainly composed of three layers of heat preservation shell 1, phase change material 2, heat exchange fluid outlet header 3, and heat exchange coil 16, specifically the first layer The heat exchange coil 4, the second heat exchange coil 5 and the third heat exchange coil 6 also include a top cover plate 7 of the box body, a heat exchange fluid inlet header 8, a fixed rod 9, an electric heating element 10, Support bar 11, support angle steel 12, U-shaped bolt 13 etc. are formed.

[0050] The first layer of heat exchange coils 4 , the second layer of heat exchange coils 5 , and the third layer of heat exchange coils are arranged in six layers and connected in parallel to the outlet header 3 and the inlet header 8 of the heat transfer fluid. The vertical direction of the heat exchange coils 16 of each layer is connected and fixed by the supporting angle steel 12 and the U-shaped bolt 13, the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com