Pointer type instrument reading method suitable for multi-view images based on machine vision

A technology of instrument reading and machine vision, which is applied in the manufacturing industry, can solve problems such as incorrect image viewing angles, and achieve the effects of low sensitivity, improved stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

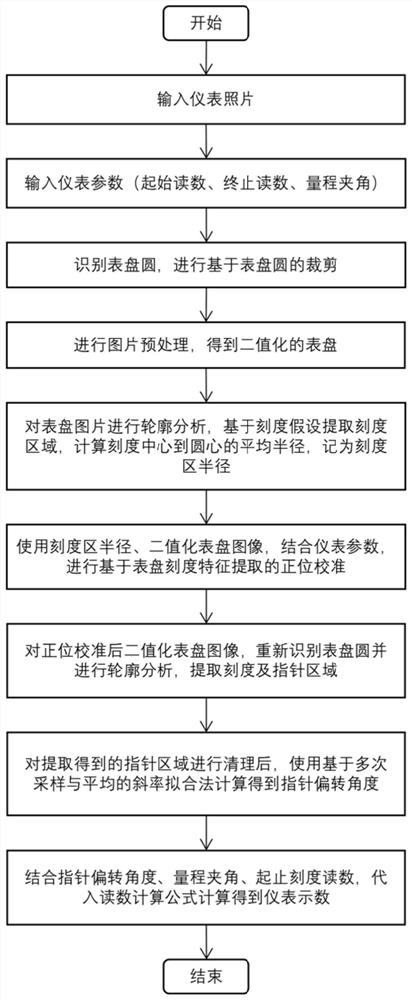

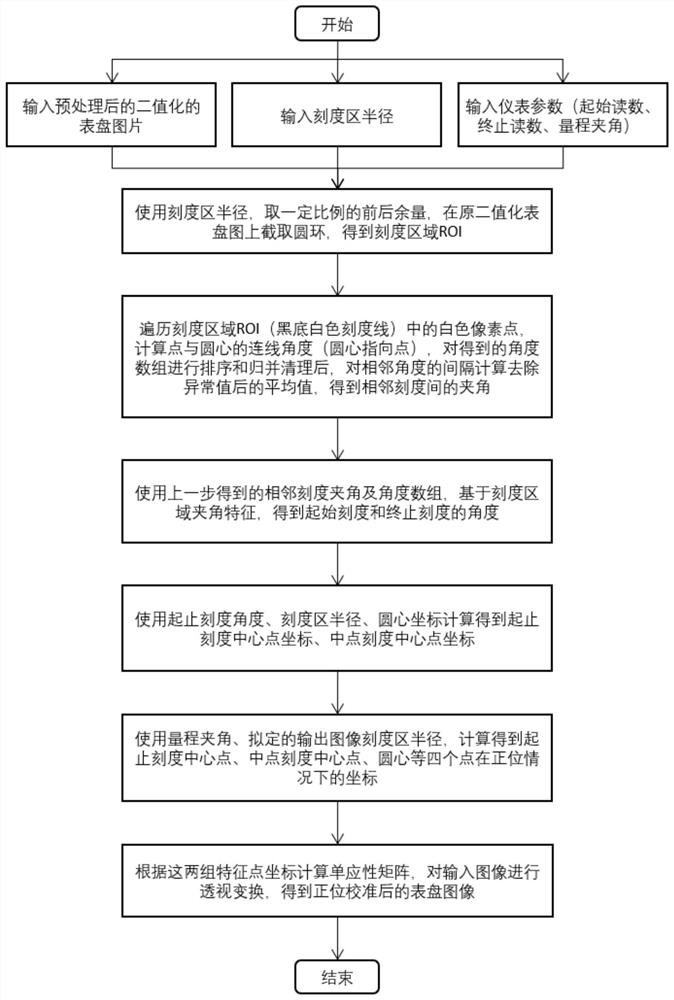

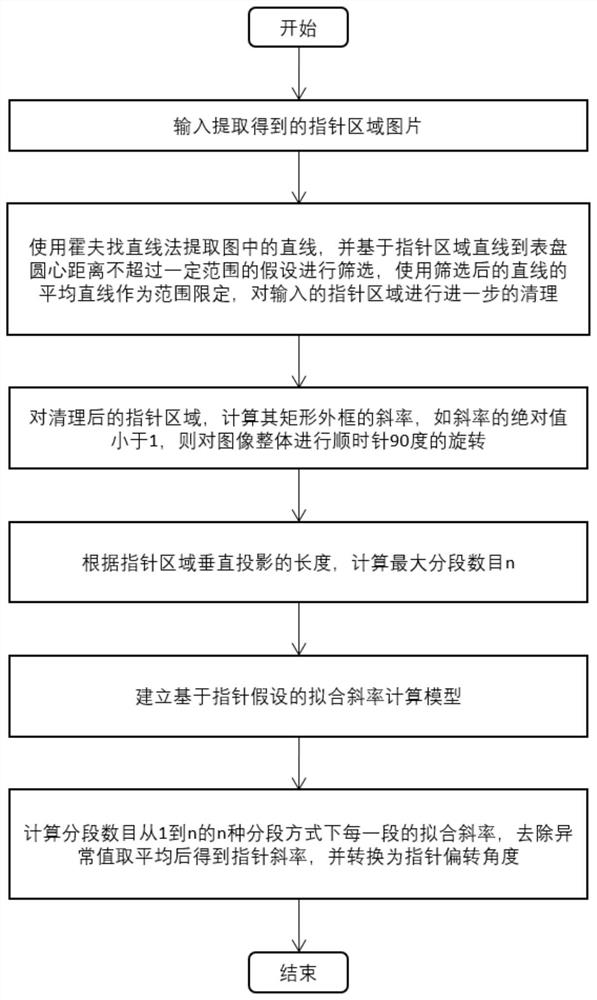

[0044] This example is a pointer meter reading method suitable for multi-view images based on machine vision. The detailed steps are:

[0045] 1. Obtain the picture of the meter to be identified and parameters such as the initial scale reading s of the instrument, the end scale reading e, and the included angle phi of the measuring range;

[0046] 2. Scale the input image proportionally, and scale the shortest side to 480 pixels;

[0047] 3. Perform preprocessing such as histogram equalization, mean filtering, and Gaussian blur on the zoomed image;

[0048] 4. For the preprocessed picture, use the Hough circle finding method to identify the dial circle, calculate the circumscribed rectangle of the dial circle based on a 5% margin, and crop the picture;

[0049] 5. Scale the cropped picture again proportionally, scale the shortest side to 480 pixels, and calculate the center coordinate O and radius r of the scaled dial circle;

[0050] 6. Perform preprocessing such as histogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com