A kind of microchannel reactor and method thereof for preparing modified nano-calcium carbonate

A microchannel reactor, nano-calcium carbonate technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, calcium carbonate/strontium/barium, etc. It can solve the problems of poor homogenization, dispersion and modification effect, and decline in material properties, so as to achieve the effect of favorable for explosive nucleation, small mixing scale and shortened reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

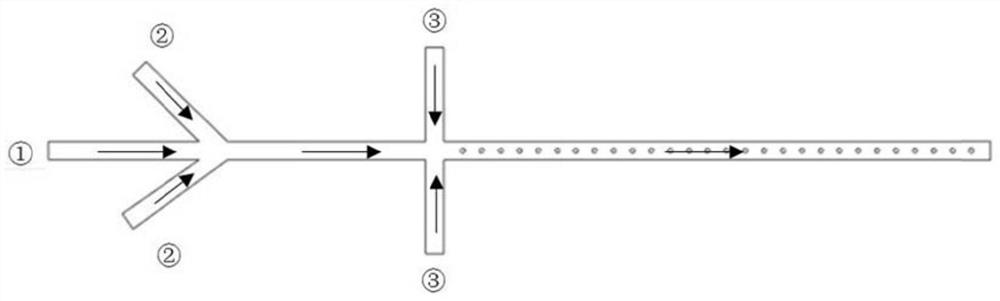

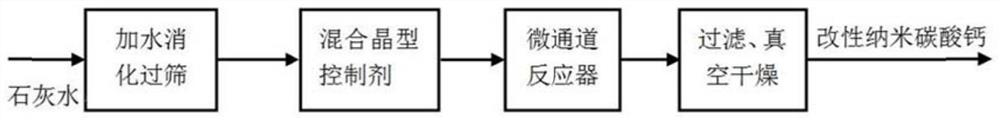

[0045] The quicklime and water are stirred and digested at a mass ratio of 1:20. After 1 hour of reaction, the slag is removed by filtration through a 200-mesh sieve to obtain calcium hydroxide slurry. The solid content of the calcium hydroxide slurry is adjusted to 3%, and a 1% sodium hexametaphosphate solution is added and fully stirred to prepare a homogeneous calcium hydroxide suspension. The calcium hydroxide suspension is continuously pumped into the main channel of the microchannel reactor at a flow rate of 0.0035m / s. At this time, the calcium hydroxide suspension is in a laminar flow state in the main channel. The flow rate is continuously pumped into the branch channels of the microchannel reactor. The calcium hydroxide suspension is wrapped by the surface modifier at the intersection of the main channel and the branch channel to form a dispersed phase together. After the calcium hydroxide suspension and the surface modifier meet in the main channel, a stable stratifi...

Embodiment 2

[0047] The quicklime and water are stirred and digested at a mass ratio of 1:5. After 1 hour of reaction, the slag is removed by filtration through a 200-mesh sieve to obtain calcium hydroxide slurry. The solid content of the calcium hydroxide slurry is adjusted to 18%, and a 1% sodium hexametaphosphate solution is added and fully stirred to prepare a homogeneous calcium hydroxide suspension. The calcium hydroxide suspension is continuously pumped into the main channel of the microchannel reactor at a flow rate of 0.003m / s. At this time, the calcium hydroxide suspension is in a laminar flow state in the main channel. The flow rate is continuously pumped into the branch channels of the microchannel reactor. The calcium hydroxide suspension is wrapped by the surface modifier at the intersection of the main channel and the branch channel to form a dispersed phase together. After the calcium hydroxide suspension and the surface modifier meet in the main channel, a stable stratifie...

Embodiment 3

[0055] The quicklime and water are stirred and digested in a mass ratio of 1:5. After 1 hour of reaction, the slag is removed by filtration through a 200-mesh sieve to obtain calcium hydroxide slurry. The solid content of the calcium hydroxide slurry is adjusted to 20%, and a 1% sodium hexametaphosphate solution is added and fully stirred to prepare a homogeneous calcium hydroxide suspension. The calcium hydroxide suspension is continuously pumped into the main channel of the microchannel reactor at a flow rate of 0.004m / s. At this time, the calcium hydroxide suspension is in a laminar flow state in the main channel. The flow rate is continuously pumped into the branch channels of the microchannel reactor. The calcium hydroxide suspension is wrapped by the surface modifier at the intersection of the main channel and the branch channel to form a dispersed phase together. After the calcium hydroxide suspension and the surface modifier meet in the main channel, a stable stratifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com