Vacuum brazing method for slender weld joint of hole-shaft matched part

A technology of hole-shaft matching and brazing method, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc. Easy to assemble and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A preferred embodiment of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution in a preferred embodiment of the present invention will be clearly and completely described.

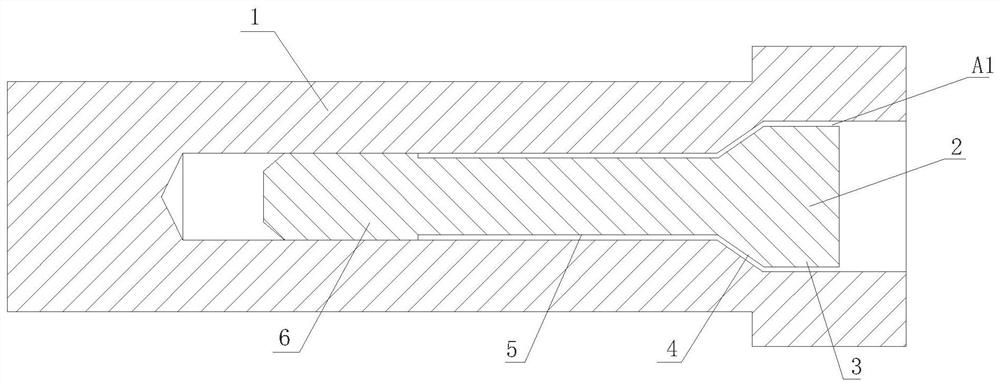

[0037] figure 1 It is a schematic diagram of the assembly of the hole-shaped part 1 and the shaft-shaped part 2. The shaft-shaped part 2 includes a large-diameter part 3, a small-diameter part 5 and a conical part 4 connecting the two. There is a welding gap of 0.05-0.1 cm on one side, and the front end of the small diameter part 5 has a clamping part 6 that can be tightly matched with the hole type part 1. The vacuum brazing method of the above-mentioned hole and shaft matching part slender welding seam includes the following steps,

[0038] 1. Check parts:

[0039] (1) Spare parts: get the hole type part 1 and the shaft type part 2, nickel-based alloy powder solder, adhesive, nickel foil with a thickness of 0.05cm; in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com